Académique Documents

Professionnel Documents

Culture Documents

Ern 1387

Transféré par

thanhhung_hyTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Ern 1387

Transféré par

thanhhung_hyDroits d'auteur :

Formats disponibles

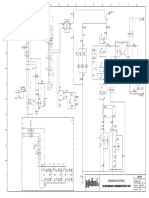

UP = 5 V 5%

(I max. 130 mA)

EN 50 178/4.98; 5.2.9.5

IEC 364-4-41: 1992; 411(PELV/SELV)

360 el.

(siehe, see, voir, vedi, vase

HEIDENHAIN D 231 929)

0.8 ... 1.2 VSS

( 1 VSS; Z0 = 120 W)

0

90 el.

A, B, R

C, D

0.2 V ... 0.85 V

( 0.5 V; Z0 = 120 W)

DIN EN 100 015 1

CECC 00015 1

360 mech.

0.8 ... 1.2 VSS

( 1 VSS; Z0 = 1 kW)

Montageanleitung

Mounting Instructions

Instructions de montage

Istruzioni di montaggio

Instrucciones de montaje

90 mech.

ERN 1387

7/2005

62S14-70

ERN 1387

HEIDENHAIN

DR. JOHANNES HEIDENHAIN GmbH

Dr.-Johannes-Heidenhain-Strae 5

83301 Traunreut, Germany

{ +49 (86 69) 31-0

| +49 (86 69) 50 61

e-mail: info@heidenhain.de

b

a

D-83301 Traunreut-Germany

1234 567

1b

7a

5b

3a

6b

2a

3b

5V

UP

5V

Sensor

0V

UN

0V

Sensor

A+

B+

5a

4b

4a

7b

1a

2b

6a

R+

C+

D+

150 m

Technical support | +49 (86 69) 31-10 00

Measuring systems { +49 (86 69) 31-31 04

e-mail: service.ms-support@heidenhain.de

TNC support

{ +49 (86 69) 31-31 01

e-mail: service.nc-support@heidenhain.de

NC programming { +49 (86 69) 31-31 03

e-mail: service.nc-pgm@heidenhain.de

PLC programming { +49 (86 69) 31-31 02

e-mail: service.plc@heidenhain.de

Lathe controls

{ +49 (7 11) 95 28 03-0

e-mail: service.hsf@heidenhain.de

www.heidenhain.de

> 100 mm

Schirm auf Gehuse

Shield on housing

Blindage sur boter

Schermo sulla carcassa

Blindaje a carcasa

> 100 mm

> 200 mm

Strquellen

Noise sources

Sources parasites

Origine del disturbo

Fuentes de interferencias

Ve 00

533 398-91 50 8/2005 H Printed in Germany nderungen vorbehalten

Subject to change without notice Sous rserve de modifications Con riserva di modifiche Sujeto a modificaciones

Elektrischen Anschluss herstellen

Electrical connection

Prparer le raccordement lectrique

Realizzare il collegamento elettrico

Establecer conexin elctrica

ERN 1387

Mae in mm

Dimensions in mm

Cotes en mm

Dimensioni in mm

Dimensiones en mm

A = Lagerung

Bearing

Roulement

Cuscinetto

Rodamiento

TO

P

k = Kundenseitige Anschlussmae

Required mating dimensions

Conditions requises pour le montage

Dimensioni di collegamento lato cliente

Cotas de montaje requeridas

Id.-Nr. 332 199-xx

Id.-Nr. 332 200-xx

Kabel einclicken und auf Anschlag schieben

Click cable into place, and push it in as far as possible

Encliqueter le cble et le pousser jusqu'en bute

Fissare il cavo e spingere fino in battuta

Doblar el cable y deslizarlo hasta el tope

2.

Md = 5 0.5 Nm

Zwei Mglichkeiten zur Demontage des Drehgebers

Two possibilities for dismounting the encoder

Deux possibilits de dmontage du capteur rotatif

Due possibilit di smontaggio dell'encoder

Dos posibilidades para el desmontaje del encoder

1.

M5 x 50 DIN 6912

SW4

Md = 5 + 0.5 Nm

a)

3.

b)

1.

SW3/SW4

Md = 1.25 Nm

SW2

1.

M5

R1

T 40 C

(40 F)

R2

T 10 C

(14 F)

4.5 mm

R1 18 mm

8 mm

R1 40 mm

R2 100 mm

ca. 360 .... 720

(C

(F)

M5 x 10

30 ... 80 C

(22 ... 176 F)

2.

M6 x 70

2.

M10

Vous aimerez peut-être aussi

- ATV 58-Manuel - Sodivar PDFDocument51 pagesATV 58-Manuel - Sodivar PDFJustin RichardPas encore d'évaluation

- Mic-V ERROR-Log 01 PDFDocument47 pagesMic-V ERROR-Log 01 PDFKHALLPas encore d'évaluation

- Bbv46396 Altivar 312 User ManualDocument256 pagesBbv46396 Altivar 312 User ManualanoopunniPas encore d'évaluation

- La Teb D 26 PDFDocument23 pagesLa Teb D 26 PDFQuentin RuidePas encore d'évaluation

- Telealarme MemcomDocument12 pagesTelealarme MemcomKarim SadjiPas encore d'évaluation

- ORONA Verification Des Cables GainesDocument11 pagesORONA Verification Des Cables GainesKhaled ZakariaPas encore d'évaluation

- CatalogueDocument768 pagesCatalogueChiboub Ben MabroukPas encore d'évaluation

- Emerson m200Document20 pagesEmerson m200Mohamed amine Benfarhat100% (1)

- DMG Encoder Deum8 16 Ed.1.0Document10 pagesDMG Encoder Deum8 16 Ed.1.0coco MPPas encore d'évaluation

- Otis France: GénéralitésDocument6 pagesOtis France: Généralitéssali noureddine100% (1)

- The Smart Controller: Installation Électrique PrécâbléeDocument60 pagesThe Smart Controller: Installation Électrique PrécâbléegomesPas encore d'évaluation

- 300 I 9010445 F 06 - BUCHER - DSV A3 - Montage - FRDocument32 pages300 I 9010445 F 06 - BUCHER - DSV A3 - Montage - FRpaul5791Pas encore d'évaluation

- Altivar 71Document108 pagesAltivar 71Martin Yauri CaceresPas encore d'évaluation

- MHN30PDBGW Installation Instruction EN PDFDocument36 pagesMHN30PDBGW Installation Instruction EN PDFEduardo HernandezPas encore d'évaluation

- Notice ANEP BOX TA V1 - 9 Web PDFDocument28 pagesNotice ANEP BOX TA V1 - 9 Web PDFcoco MPPas encore d'évaluation

- 708 V2 WebDocument38 pages708 V2 WebEl deo nguema100% (1)

- ADVANCED K2 - 3VF Gearless - Fuji Frenic Lift2 - R02 (FR)Document23 pagesADVANCED K2 - 3VF Gearless - Fuji Frenic Lift2 - R02 (FR)Khaled ZakariaPas encore d'évaluation

- Vimec A28Document17 pagesVimec A28Alessandro MuraPas encore d'évaluation

- Digicode CDVI DG502Document8 pagesDigicode CDVI DG502Aidolan UlrichPas encore d'évaluation

- VVVF Repairing Tips Fermator DoorDocument13 pagesVVVF Repairing Tips Fermator DoorNunFraPas encore d'évaluation

- DMG Technical CatalogueDocument138 pagesDMG Technical CatalogueRomeuPas encore d'évaluation

- Instruction Et Reglage Des Portes FermatorDocument21 pagesInstruction Et Reglage Des Portes FermatorDjoPas encore d'évaluation

- VVVF Fuji Frenic Lift2Document32 pagesVVVF Fuji Frenic Lift2Amine MohamedPas encore d'évaluation

- Notice Digicode CDVI DG21-DG22-FRDocument5 pagesNotice Digicode CDVI DG21-DG22-FROlivier CutayaPas encore d'évaluation

- Mli 2Document11 pagesMli 2ZoubaierPas encore d'évaluation

- 917CC000 S.COM Doc - ProprietaireDocument9 pages917CC000 S.COM Doc - ProprietaireZomaarPas encore d'évaluation

- 4/16 VVVF: Argani GearsDocument6 pages4/16 VVVF: Argani GearsYiannis ToufexisPas encore d'évaluation

- Otis Mcs321 Ovf30 Avec Outil Babasse DefautDocument90 pagesOtis Mcs321 Ovf30 Avec Outil Babasse DefautliftliftPas encore d'évaluation

- Montageanleitung F PDFDocument19 pagesMontageanleitung F PDFbaiadilPas encore d'évaluation

- Ba Ek260 FRDocument135 pagesBa Ek260 FRKarim TadjeddinePas encore d'évaluation

- Man-5011 Slim - 03.2019Document48 pagesMan-5011 Slim - 03.2019Coil98Pas encore d'évaluation

- Outil Sodimas MobeeDocument2 pagesOutil Sodimas MobeeMohamed ABIDAPas encore d'évaluation

- Manuel Console Via SERIE Babasse BleueDocument17 pagesManuel Console Via SERIE Babasse BleueKarim ChrifPas encore d'évaluation

- Module 6 - Presentation Ascenseur Et SoumissionDocument13 pagesModule 6 - Presentation Ascenseur Et Soumissionkriga OuagalPas encore d'évaluation

- Etma tm2 Tam2Document1 pageEtma tm2 Tam2cedric romeraPas encore d'évaluation

- ASP16 Manuel D39installation Et de Maintenance Pour Ascenseurs Electriques V5.xxEd04Document64 pagesASP16 Manuel D39installation Et de Maintenance Pour Ascenseurs Electriques V5.xxEd04Aurélien DRICOTPas encore d'évaluation

- Ee540 PDFDocument3 pagesEe540 PDFJosePas encore d'évaluation

- Brochure GenesisDocument15 pagesBrochure Genesiskonate.madou20Pas encore d'évaluation

- GTW9Document1 pageGTW9George PontoniPas encore d'évaluation

- VK3i Sodimas FRDocument8 pagesVK3i Sodimas FRthunder100% (1)

- FUJI Variateurs FRENIC Mini Démarrage RapideDocument16 pagesFUJI Variateurs FRENIC Mini Démarrage Rapidecoco MPPas encore d'évaluation

- Documentation Technique Technical Documentation: TouchDocument76 pagesDocumentation Technique Technical Documentation: TouchAbdel YahyaouiPas encore d'évaluation

- Documentation VSpace Sodimas PDFDocument40 pagesDocumentation VSpace Sodimas PDFDjelloul AbdelhadiPas encore d'évaluation

- TelechargementM3 1 0Document16 pagesTelechargementM3 1 0paul5791Pas encore d'évaluation

- Brother DT6-B927, B928Document70 pagesBrother DT6-B927, B928Chooper BikePas encore d'évaluation

- Do2000 Open2000 Open2002Document20 pagesDo2000 Open2000 Open2002ZoubaierPas encore d'évaluation

- Q Playboard-R2 040517-0 FR Ed.2Document46 pagesQ Playboard-R2 040517-0 FR Ed.2younes100% (2)

- ZIEHL-ABEGG Operating Instructions ZAtop SM200 40C a-TBA10 04-F FR 1626Document64 pagesZIEHL-ABEGG Operating Instructions ZAtop SM200 40C a-TBA10 04-F FR 1626AliRouyouPas encore d'évaluation

- Liste Des Defaults SANEIDocument4 pagesListe Des Defaults SANEISilviuPas encore d'évaluation

- QITouch-Découverte Et Mise en service-V3-Fr-memento-A4Document31 pagesQITouch-Découverte Et Mise en service-V3-Fr-memento-A4Yannice LefroyPas encore d'évaluation

- Schindler 3300Document32 pagesSchindler 3300coco MP100% (1)

- Fermator Vvf4 Modèle 40-10 PM SLIMDocument24 pagesFermator Vvf4 Modèle 40-10 PM SLIMcoco MPPas encore d'évaluation

- MRCDocument65 pagesMRCAbdo EmitPas encore d'évaluation

- Componentes FRDocument124 pagesComponentes FRPedro KalvinPas encore d'évaluation

- Notice VF7Document25 pagesNotice VF7Olivier CuencaPas encore d'évaluation

- Circuits Logiques Par PDFDocument34 pagesCircuits Logiques Par PDFMohamed MoudinePas encore d'évaluation

- 1XP8001-1 1XP8001-2: Drehimpulsgeber Codeur Rotatif D'impulsion Encoder Impulsi Di RotazioneDocument20 pages1XP8001-1 1XP8001-2: Drehimpulsgeber Codeur Rotatif D'impulsion Encoder Impulsi Di Rotazionejohxav10Pas encore d'évaluation

- Ecn 1313 ManualDocument2 pagesEcn 1313 ManualPerry ElevatorsPas encore d'évaluation

- GEB161.1E Fiche Produit FR PDFDocument4 pagesGEB161.1E Fiche Produit FR PDFe-genieclimatique.comPas encore d'évaluation

- B&K Vibro Senzor DatasheetDocument9 pagesB&K Vibro Senzor DatasheetIvan JablanovićPas encore d'évaluation