Académique Documents

Professionnel Documents

Culture Documents

Hoja Tecnica TP08

Transféré par

infoCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Hoja Tecnica TP08

Transféré par

infoDroits d'auteur :

Formats disponibles

TP08

HYDRAULIC

TRASH PUMP

(TP0813, TP08013H, TP08013W)

USER MANUAL

Safety, Operation and Maintenance

© 2014 STANLEY Black & Decker, Inc.

New Britain, CT 06053

U.S.A.

66364 10/2022 Ver. 28

DECLARATIONS OF CONFORMITY

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Vervier, Patrick

Je soussigné: Surname and First names/Familiennname und Vornamen/Nom et prénom/Nombre y apellido/Cognome e nome

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

1. Category: Trash Pump, Hydraulic

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca STANLEY

3. Type/Typ/Type/Tipo/Tipo: TP08013, TP08013H, TP08013B,TP08013W

4. Serial number of equipment:

Seriennummer des Geräts:

Numéro de série de l’équipement:

Numero de serie del equipo:

All

Matricola dell´attrezzatura:

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Directive/Standards No. Approved body

Richtlinie/Standards Nr Prüfung durch

Directives/Normes Numéro Organisme agréé

Directriz/Los Normas No Aprobado

Direttiva/Norme n. Collaudato

EN 809:1998/A1:2009 Self

Machinery Directive 2006/42/EC:2006 Self

5. Special Provisions: None

Spezielle Bestimmungen:

Dispositions particulières:

Provisiones especiales:

Disposizioni speciali:

6. Representative in the Union: Patrick Vervier, STANLEY Dubuis 17-19, rue Jules Berthonneau- CS 73406 41034 Blois CEDEX, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a STANLEY Infrastructure, Milwaukie, Oregon USA Date/Datum/le/Fecha/Data 11/08/2022

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione Engineering Manager

Test Report #07072016TP08

2 ► TP08 User Manual

DECLARATION OF CONFORMITY

______________________________________________________________________

I, the undersigned:

Vervier, Patrick

Surname and First names

hereby declare that the equipment specified hereunder:

1. Category: Trash Pump, Hydraulic

2. Make: STANLEY

3. Type: TP08013, TP08013H, TP08013B, TP08013L11, TP08013W

4. Serial number of equipment:

All

Has been manufactured in conformity with

Directive/Standards No. Approved body

EN 809:1998/A1:2009 Self

Supply of Machinery S.I. 2008/1597 Self

(Safety) Regulations

2008

5. Special Provisions: None

6. Representative in the Union: Patrick Vervier, STANLEY Dubuis 17-19, rue Jules Berthonneau- CS 73406 41034 Blois CEDEX, France.

Done at STANLEY Infrastructure, Milwaukie, Oregon USA Date 11/08/2022

Signature

Position Engineering Manager

TP08 User Manual ◄ 3

TABLE OF CONTENTS

SAFETY SYMBOLS..................................................................................................................................................5

SAFETY PRECAUTIONS........................................................................................................................................6

TOOL STICKERS & TAGS.......................................................................................................................................7

HOSE TYPES...........................................................................................................................................................8

HOSE RECOMMENDATIONS.................................................................................................................................9

HTMA/EHTMA REQUIREMENTS.........................................................................................................................10

OPERATION........................................................................................................................................................... 11

TOOL PROTECTION & CARE...............................................................................................................................13

TROUBLESHOOTING...........................................................................................................................................14

SPECIFICATIONS..................................................................................................................................................15

ACCESSORIES......................................................................................................................................................15

MAINTENANCE......................................................................................................................................................15

TP08 BODY ILLUSTRATION.................................................................................................................................16

TP08 IMPELLER ILLUSTRATION.........................................................................................................................17

TP08 MOTOR ILLUSTRATION..............................................................................................................................18

UNDERWATER TOOLS DEPTH GUIDELINE......................................................................................................19

To fill out a product warranty validation form, and for information on your warranty,

visit www.stanleyinfrastructure.com and select the Company tab > Warranty.

Note: The warranty validation record must be submitted to validate the warranty.

SERVICING: This manual contains safety, operation and routine maintenance instructions. STANLEY Infrastructure

recommends that servicing of hydraulic tools, other than routine maintenance, must be performed by an authorized

and certified dealer. Please read the following warning.

SERIOUS INJURY OR DEATH COULD RESULT FROM THE IMPROPER REPAIR OR

SERVICE OF THIS TOOL.

REPAIRS AND / OR SERVICE TO THIS TOOL MUST ONLY BE DONE BY AN

AUTHORIZED AND CERTIFIED DEALER.

For the nearest certified dealer, call STANLEY Infrastructure at (503) 659-5660 and ask for a Customer Service Representative.

4 ► TP08 User Manual

SAFETY SYMBOLS

Safety symbols and signal words, as shown below, are used to emphasize all operator, maintenance and repair

actions which, if not strictly followed, could result in a life-threatening situation, bodily injury or damage to equipment.

This is the safety alert symbol. It is used to alert you to potential personal injury

hazards. Obey all safety messages that follow this symbol to avoid possible

injury or death.

This safety alert and signal word indicates an imminently hazardous situation

which, if not avoided, will result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This safety alert and signal word indicates a potentially hazardous situation

which, if not avoided, could result in death or serious injury.

This signal word indicates a potentially hazardous situation which, if not avoided,

may result in property damage.

This signal word indicates a situation which, if not avoided, will result in damage

to the equipment.

This signal word indicates a situation which, if not avoided, may result in damage

to the equipment.

Always observe safety symbols. They are included for your safety and for the protection of the tool.

LOCAL SAFETY REGULATIONS

Enter any local safety regulations here. Keep these instructions in an area accessible to the operator and

maintenance personnel.

TP08 User Manual ◄ 5

SAFETY PRECAUTIONS

Tool operators and maintenance personnel must always pressure rating of 2500 psi/175 bar.

comply with the safety precautions given in this manual • Be sure all hose connections are tight.

and on the stickers and tags attached to the tool and

hose. • The hydraulic circuit control valve must be in the

“OFF” position when coupling or uncoupling the tool.

These precautions are given for your safety. Review Wipe all couplers clean before connecting. Failure

them carefully before operating the tool and before to do so may result in damage to the quick couplers

performing maintenance. and cause overheating. Use only lint-free cloths.

Supervising personnel should develop additional • Do not operate the tool at oil temperatures above

precautions relating to the specific work area and local 140 °F/60 °C. Operation at higher oil temperatures

safety regulations. Place the added precautions in the can cause operator discomfort and may cause

space provided damage to the tool.

The models TP08 Hydraulic Trash Pump will provide • Do not operate a damaged, improperly adjusted or

safe and dependable service if operated in accordance incompletely assembled tool.

with the instructions given in this manual. Read and

understand this manual and any stickers and tags • To avoid personal injury or equipment damage,

attached to the tool and hoses before operation. Failure all tool repair, maintenance and service must only

to do so could result in personal injury or equipment be performed by authorized and properly trained

damage. personnel.

• Do not exceed the rated limits of the tool or use the

tool for applications beyond its design capacity.

• Always keep critical tool markings, such as labels

and warning stickers, legible.

• Always replace parts with replacement parts

recommended by STANLEY.

• Check fastener tightness often and before each use

• Operator must start in a work area without

daily.

bystanders. The operator must be familiar with all

prohibited work areas such as excessive slopes and • Do not put your hands or any other body part under

dangerous terrain conditions. the volute while the trash pump is running.

• Establish a training program for all operators to • Do not lift the trash pump by pulling on the hydraulic

ensure safe operations. hoses. Use a suitable line fastened to the trash

pump handle.

• Do not operate the tool unless thoroughly trained or

under the supervision of an instructor. • Do not point water discharge toward bystanders.

• Always wear safety equipment such as goggles,

head protection, and safety shoes at all times when

operating the tool.

• Do not inspect or clean the tool while the hydraulic

power source is connected. Accidental engagement

of the tool can cause serious injury.

• Do not install or remove this tool while the hydraulic

power source is connected. Accidental engagement

of the tool can cause serious injury.

• Never operate the tool near energized transmission

lines. Know the location of buried or covered

services before starting work.

• Do not wear loose fitting clothing when operating the

tool. Loose fitting clothing can become entangled

with the tool and cause serious injury.

• Supply hoses must have a minimum working

6 ► TP08 User Manual

TOOL STICKERS & TAGS

CAUTION

D

30lpm at 138bar

EHTMA CATEGORY

88864 88345

TOOL NAME TAG IMPORT NAME TAG (CE MODELS)

NOTE:

THE INFORMATION LISTED ON THE STICKERS

SHOWN, MUST BE LEGIBLE AT ALL TIMES.

REPLACE DECALS IF THEY BECOME WORN OR

DAMAGED. REPLACEMENTS ARE AVAILABLE

FROM YOUR LOCAL STANLEY DISTRIBUTOR.

The safety tags (P/N 15875 and 88346) at right

and below are attached to the tool when shipped

from the factory. Read and understand the safety D A N G E R D A N G E R

instructions listed on this tag before removal. We

suggest you retain this tag and attach it to the tool

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CER- D. DO NOT LIFT OR CARRY TOOL BY THE HOSES. DO

when not in use. TIFIED AS NON-CONDUCTIVE WHEN USING HYDRAULIC

TOOLS ON OR NEAR ELECTRICAL LINES MAY RESULT IN

NOT ABUSE HOSE. DO NOT USE KINKED, TORN OR

DAMAGED HOSE.

DEATH OR SERIOUS INJURY. 3. MAKE SURE HYDRAULIC HOSES ARE PROPERLY CON-

BEFORE USING HOSE LABELED AND CERTIFIED AS NON- NECTED TO THE TOOL BEFORE PRESSURING SYSTEM.

CONDUCTIVE ON OR NEAR ELECTRIC LINES BE SURE THE SYSTEM PRESSURE HOSE MUST ALWAYS BE CON-

HOSE IS MAINTAINED AS NON-CONDUCTIVE. THE HOSE NECTED TO TOOL “IN” PORT. SYSTEM RETURN HOSE

SHOULD BE REGULARLY TESTED FOR ELECTRIC CUR- MUST ALWAYS BE CONNECTED TO TOOL “OUT” PORT.

RENT LEAKAGE IN ACCORDANCE WITH YOUR SAFETY REVERSING CONNECTIONS MAY CAUSE REVERSE

DEPARTMENT INSTRUCTIONS. TOOL OPERATION WHICH CAN RESULT IN SEVERE

PERSONAL INJURY.

2. A HYDRAULIC LEAK OR BURST MAY CAUSE OIL INJEC- 4. DO NOT CONNECT OPEN-CENTER TOOLS TO CLOSED-

TION INTO THE BODY OR CAUSE OTHER SEVERE CENTER HYDRAULIC SYSTEMS. THIS MAY RESULT IN

PERSONAL INJURY. LOSS OF OTHER HYDRAULIC FUNCTIONS POWERED BY

A. DO NOT EXCEED SPECIFIED FLOW AND PRESSURE THE SAME SYSTEM AND/OR SEVERE PERSONAL INJURY.

FOR THIS TOOL. EXCESS FLOW OR PRESSURE MAY 5. BYSTANDERS MAY BE INJURED IN YOUR WORK AREA.

CAUSE A LEAK OR BURST. KEEP BYSTANDERS CLEAR OF YOUR WORK AREA.

B. DO NOT EXCEED RATED WORKING PRESSURE OF 6. WEAR HEARING, EYE, FOOT, HAND AND HEAD PRO-

HYDRAULIC HOSE USED WITH THIS TOOL. EXCESS TECTION.

PRESSURE MAY CAUSE A LEAK OR BURST.

7. TO AVOID PERSONAL INJURY OR EQUIPMENT DAMAGE,

C. CHECK TOOL HOSE COUPLERS AND CONNECTORS ALL TOOL REPAIR MAINTENANCE AND SERVICE MUST

DAILY FOR LEAKS. DO NOT FEEL FOR LEAKS WITH

ONLY BE PERFORMED BY AUTHORIZED AND PROPERLY

YOUR HANDS. CONTACT WITH A LEAK MAY RESULT TRAINED PERSONNEL.

IN SEVERE PERSONAL INJURY.

I M P O R T A N T I M P O R T A N T

READ OPERATION MANUAL AND READ OPERATION MANUAL AND

SAFETY INSTRUCTIONS FOR THIS SAFETY INSTRUCTIONS FOR THIS

TOOL BEFORE USING IT. TOOL BEFORE USING IT.

USE ONLY PARTS AND REPAIR USE ONLY PARTS AND REPAIR

PROCEDURES APPROVED BY PROCEDURES APPROVED BY

STANLEY AND DESCRIBED IN THE STANLEY AND DESCRIBED IN THE

OPERATION MANUAL. OPERATION MANUAL.

TAG TO BE REMOVED ONLY BY TAG TO BE REMOVED ONLY BY

TOOL OPERATOR. TOOL OPERATOR.

SEE OTHER SIDE SEE OTHER SIDE

88346 88346

SAFETY TAG, FRENCH P/N 88346 (Shown smaller

then actual size, French translation of 15875) SAFETY TAG P/N 15875 (Shown smaller then actual size)

TP08 User Manual ◄ 7

HOSE TYPES

The rated working pressure of the hydraulic hose must be equal to or higher than the relief valve setting on the

hydraulic system. There are three types of hydraulic hose that meet this requirement and are authorized for use with

STANLEY hydraulic tools. They are:

Certified non-conductive — constructed of thermoplastic or synthetic rubber inner tube, synthetic fiber braid

reinforcement, and weather resistant thermoplastic or synthetic rubber cover. Hose labeled certified non-

conductive is the only hose authorized for use near electrical conductors.

Wire-braided (conductive) — constructed of synthetic rubber inner tube, single or double wire braid

reinforcement, and weather resistant synthetic rubber cover. This hose is conductive and must never be used

near electrical conductors.

Fabric-braided (not certified or labeled non-conductive) — constructed of thermoplastic or synthetic rubber

inner tube, synthetic fiber braid reinforcement, and weather resistant thermoplastic or synthetic rubber cover.

This hose is not certified non-conductive and must never be used near electrical conductors.

HOSE SAFETY TAGS

To help ensure your safety, the following DANGER tags are attached to all hose purchased from STANLEY. DO

NOT REMOVE THESE TAGS.

If the information on a tag is illegible because of wear or damage, replace the tag immediately. A new tag may be

obtained from your STANLEY Distributor.

THE TAG SHOWN BELOW IS ATTACHED TO “CERTIFIED NON-CONDUCTIVE” HOSE

D A N G E R D A N G E R

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

1. FAILURE TO USE HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE 3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE

WHEN USING HYDRAULIC TOOLS ON OR NEAR ELECTRIC LINES MAY RESULT IN OR HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE.

DEATH OR SERIOUS INJURY. KEEP HOSE AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT

CONTACT DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION

FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY

AND SEVERE PERSONAL INJURY.

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND

ELECTRIC LINES. 4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, ABRASION, CUTTING, OR

CONTACT WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT

2. BEFORE USING HYDRAULIC HOSE LABELED AND CERTIFIED AS NON-CONDUCTIVE USE HOSE TO PULL OR LIFT TOOLS, POWER UNITS, ETC.

ON OR NEAR ELECTRIC LINES. WIPE THE ENTIRE LENGTH OF THE HOSE AND FITTING 5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAM-

WITH A CLEAN DRY ABSORBENT CLOTH TO REMOVE DIRT AND MOISTURE AND TEST AGE TO COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE

HOSE FOR MAXIMUM ALLOWABLE CURRENT LEAKAGE IN ACCORDANCE WITH SAFETY IMMEDIATELY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

DEPARTMENT INSTRUCTIONS.

6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

SEE OTHER SIDE SEE OTHER SIDE

SIDE 1 SIDE 2

(Shown smaller than actual size)

THE TAG SHOWN BELOW IS ATTACHED TO “CONDUCTIVE” HOSE.

D A N G E R D A N G E R

DO NOT REMOVE THIS TAG

DO NOT REMOVE THIS TAG

1. DO NOT USE THIS HYDRAULIC HOSE ON OR NEAR ELECTRIC LINES. THIS HOSE IS 5. CHECK ENTIRE HOSE FOR CUTS CRACKS LEAKS ABRASIONS, BULGES, OR DAMAGE TO

NOT LABELED OR CERTIFIED AS NON-CONDUCTIVE. USING THIS HOSE ON OR NEAR COUPLINGS IF ANY OF THESE CONDITIONS EXIST, REPLACE THE HOSE IMMEDIATELY.

ELECTRICAL LINES MAY RESULT IN DEATH OR SERIOUS INJURY. NEVER USE TAPE OR ANY DEVICE TO ATTEMPT TO MEND THE HOSE.

2. FOR PROPER AND SAFE OPERATION MAKE SURE THAT YOU HAVE BEEN PROPERLY 6. AFTER EACH USE STORE IN A CLEAN DRY AREA.

TRAINED IN CORRECT PROCEDURES REQUIRED FOR WORK ON OR AROUND ELEC-

TRIC LINES.

3. DO NOT EXCEED HOSE WORKING PRESSURE OR ABUSE HOSE. IMPROPER USE OR

HANDLING OF HOSE COULD RESULT IN BURST OR OTHER HOSE FAILURE. KEEP HOSE

AS FAR AWAY AS POSSIBLE FROM BODY AND DO NOT PERMIT DIRECT CONTACT

DURING USE. CONTACT AT THE BURST CAN CAUSE BODILY INJECTION AND SEVERE

PERSONAL INJURY.

4. HANDLE AND ROUTE HOSE CAREFULLY TO AVOID KINKING, CUTTING, OR CONTACT

WITH HIGH TEMPERATURE SURFACES. DO NOT USE IF KINKED. DO NOT USE HOSE TO

PULL OR LIFT TOOLS, POWER UNITS, ETC.

SEE OTHER SIDE SEE OTHER SIDE

SIDE 1 SIDE 2

(Shown smaller than actual size)

8 ► TP08 User Manual

Tool to Hydraulic Circuit Hose Oil Flow Hose Lengths Inside Diameter USE Min. Working Pressure

Recommendations GPM LPM FEET METERS INCH MM (Press/Return) PSI BAR

The chart to the right shows recommended Certified Non-Conductive Hose - Fiber Braid - for Utility Bucket Trucks

minimum hose diameters for various 4-9 15-34 up to 10 up to 3 3/8 10 Both 2250 155

hose lengths based on gallons per minute Conductive Hose - Wire Braid or Fiber Braid -DO NOT USE NEAR ELECTRICAL CONDUCTORS

(GPM)/liters per minute (LPM). These 4-6 15-23 up to 25 up to 7.5 3/8 10 Both 2500 175

recommendations are intended to keep return

4-6 15-23 26-100 7.5-30 1/2 13 Both 2500 175

line pressure (back pressure) to a minimum

5-10.5 19-40 up to 50 up to 15 1/2 13 Both 2500 175

acceptable level to ensure maximum tool

performance. 5-10.5 19-40 51-100 15-30 5/8 16 Both 2500 175

5/8 16 Pressure 2500 175

This chart is intended to be used for hydraulic 5-10.5 19-40 100-300 30-90

tool applications only based on STANLEY tool 3/4 19 Return 2500 175

operating requirements and should not be 10-13 38-49 up to 50 up to 15 5/8 16 Both 2500 175

used for any other applications. 5/8 16 Pressure 2500 175

10-13 38-49 51-100 15-30

All hydraulic hose must have at least a 3/4 19 Return 2500 175

rated minimum working pressure equal to 3/4 19 Pressure 2500 175

10-13 38-49 100-200 30-60

the maximum hydraulic system relief valve 1 25.4 Return 2500 175

setting. 5/8 16 Pressure 2500 175

13-16 49-60 up to 25 up to 8

All hydraulic hose must meet or exceed 3/4 19 Return 2500 175

specifications as set forth by SAE J517. 3/4 19 Pressure 2500 175

13-16 49-60 26-100 8-30

1 25.4 Return 2500 175

PRESSURE

HOSE RECOMMENDATIONS

<<< FLOW

RETURN

FLOW >>>

Figure 1. Typical Hose Connections

TP08 User Manual ◄ 9

HTMA/EHTMA REQUIREMENTS

HTMA / EHTMA REQUIREMENTS

TOOL TYPE

HTMA

TYPE I TYPE II TYPE RR TYPE III

HYDRAULIC SYSTEM REQUIREMENTS

4-6 GPM 7-9 GPM 9-10.5 GPM 11-13 GPM

Flow range

(15-23 LPM) (26-34 LPM) (34-40 LPM) (42-49 LPM)

Nominal operating pressure 1500 psi 1500 psi 1500 psi 1500 psi

(At the power supply outlet) (103 bar) (103 bar) (103 bar) (103 bar)

System relief valve setting 2100-2250 psi 2100-2250 psi 2200-2300 psi 2100-2250 psi

(At the power supply outlet) (145-155 bar) (145-155 bar) (152-159 bar) (145-155 bar)

Maximum back pressure 250 psi 250 psi 250 psi 250 psi

(At tool end of the return hose) (17 bar) (17 bar) (17 bar) (17 bar)

Measured at a max fluid viscosity of: 400 ssu* 400 ssu* 400 ssu* 400 ssu*

(At minimum operating temperature) (82 centistokes) (82 centistokes) (82 centistokes) (82 centistokes)

Temperature: Sufficient heat rejection capacity to limit 140° F 140° F 140° F 140° F

maximum fluid temperature to: (60° C) (60° C) (60° C) (60° C)

(At maximum expected ambient temperature)

3 hp 5 hp 6 hp 7 hp

Minimum cooling capacity at a temperature difference of (2.24 kW) (3.73 kW) (5.22 kW) (4.47 kW)

between ambient and fluid temps 40° F 40° F 40° F 40° F

(22° C) (22° C) (22° C) (22° C)

Note: Do not operate the tool at oil temperatures above 140° F (60° C). Operation at higher temperatures can cause operator

discomfort at the tool.

Filter minimum full-flow filtration 25 microns 25 microns 25 microns 25 microns

Sized for flow of at least: 30 GPM 30 GPM 30 GPM 30 GPM

(For cold temp startup and maximum dirt-holding capacity) (114 LPM) (114 LPM) (114 LPM) (114 LPM)

Hydraulic fluid, petroleum based (premium grade, anti- 100-400 ssu 100-400 ssu 100-400 ssu 100-400 ssu

wear, non-conductive) Viscosity (at minimum and maximum (20-82 (20-82 (20-82 (20-82

operating temps) centistokes) centistokes) centistokes) centistokes)

Note: When choosing hydraulic fluid, the expected oil temperature extremes that will be experienced in service determine the most

suitable temperature viscosity characteristics. Hydraulic fluids with a viscosity index over 140 will meet the requirements over a wide

range of operating temperatures.

*SSU = Saybolt Seconds Universal

CLASSIFICATION

EHTMA

HYDRAULIC SYSTEM

REQUIREMENTS

B C D

3.5-4.3 GPM 4.7-5.8 GPM 7.1-8.7 GPM 9.5-11.6 GPM 11.8-14.5 GPM

Flow range (13.5-16.5 (18-22 LPM) (27-33 LPM) (36-44 LPM) (45-55 LPM)

LPM)

Nominal operating pressure 1870 psi 1500 psi 1500 psi 1500 psi 1500 psi

(At the power supply outlet) (129 bar) (103 bar) (103 bar) (103 bar) (103 bar)

System relief valve setting 2495 psi 2000 psi 2000 psi 2000 psi 2000 psi

(At the power supply outlet) (172 bar) (138 bar) (138 bar) (138 bar) (138 bar)

Note: These are general hydraulic system requirements. See tool specification page for tool specific requirements.

10 ► TP08 User Manual

OPERATION

PREPARATION PROCEDURES Do not raise or lower the trash pump by its hoses or

couplers.

CHECK POWER SOURCE

1. Using a calibrated flow meter and pressure gauge,

make sure the hydraulic power source develops a

flow of 7-10 GPM/26-38 LPM at 2000 psi/140 bar.

2. Make certain that the power source is equipped with Never point the hose at bystanders.

a relief valve set to open at 2100-2250 psi/145-155

bar maximum. 4. Turn on the hydraulic power source. Watch for solids

3. Make certain that the power source return pressure in the liquid being pumped. If solids are excessive,

does not exceed 250 psi/17 bar. the discharge flow might decrease. If this happens,

stop the trash pump and check for the cause of the

4. Make sure the trash pump inlet is clear of debris. problem.

Remove any obstruction before operating.

Under some conditions, the liquid being pumped

CONNECT HOSES might be slowed enough so It can no longer push

1. Wipe all hose couplers with a clean lint free cloth particles in the liquid. If this happens, particles can

before making connections. accumulate in the pumping chamber, causing further

restriction. The impeller then acts as a “grinding

wheel” which causes accelerated trash pump wear.

Reduced liquid flow can be caused by the following:

• The trash pump sinks into solids at the bottom

of the hole.

Do not connect pressure to the return port.

Motor shaft seal limit Is 250 psl/17 bar. • The end of the outlet hose is too high, causing

an excessive lift height for the column of liquid

2. Connect the hoses from the hydraulic power source being pushed by the trash pump. This slows the

to the couplers on the trash pump or trash pump flow of liquid to a level where it can no longer

hoses. Connect the return hose first and disconnect carry solids.

it last to minimize or avoid trapped pressure within • The flow and pressure of hydraulic fluid to the

the trash pump motor. trash pump is too low, which reduces impeller

Note: If uncoupled hoses are left in the sun, pressure speed. A 20 percent decrease in hydraulic

increase inside the hoses might make them difficult fluid flow can reduce pump performance by 50

to connect. Whenever possible, connect the free percent. When operating at reduced hydraulic

ends of the hoses together. flow and pressure, the end of the outlet hose

should not be more than 30 ft/9 m above the

3. Observe the arrow on the couplers to ensure that the

liquid.

flow is in the proper direction. The female coupler on

the trash pump is the inlet (pressure) coupler. Note: It will not damage the pump to operate it “dry.”

PUMP OPERATION 5. When pumping is complete, set the hydraulic control

valve to the “OFF” posi tion. Lift the trash pump

1. Observe all safety precautions. from the work area using the rope or cable to avoid

2. Attach a 4-inch/102 mm diameter fire hose to the damage to the hoses or couplers.

trash pump outlet. For best performance, keep the

fire hose as short as possible and lay it out to avoid

sharp bends or kinks.

Do not attach a nozzle to the outlet end of the fire Observe the following for trash pump

hose. For high-pressure water pumping, use a protection and care.

STANLEY SM20 or SM50 and nozzle. The TP08

is designed for high GPM water flow at low water 6. The trash pump must maintain a minimum impeller

pressure (head). speed in order to move solid particles through the

3. Attach a rope or cable to the trash pump’s handle. pump. While pumping liquids containing large solids,

Lower the trash pump into the liquid to be pumped. monitor the flow from the outlet of the fire hose. If it

TP08 User Manual ◄ 11

OPERATION

begins to slow, turn off the hydraulic power source

and lift the trash pump from the work area.

Disconnect the hydraulic hoses and clean at the

water hose and the pumping chamber.

Pumping liquids with a solids-to liquid ratio greater

than 30 percent will cause impeller wear.

7. To maintain optimum performance, it is good practice

to periodically inspect the impeller for wear or

damage. This is especially important following the

pumping of liquids containing sharp, abrasive solids.

COLD WEATHER OPERATION

If the trash pump is to be used during cold weather,

preheat the hydraulic fluid at low power source speed.

When using recommended fluids, fluid should be at or

above 50 °F/10 °C (400 ssu/82 centistokes) before use.

Damage to the hydraulic system or pump motor seals

can result if the fluid is too viscous or thick.

12 ► TP08 User Manual

TOOL PROTECTION & CARE

In addition to the safety precautions found

in this manual, observe the following for

equipment protection and care.

• Make sure all couplers are wiped clean before • Always keep critical tool markings, such as warning

connection. stickers and tags, legible.

• The hydraulic circuit control valve must be in • Tool repair should be performed by experienced

the “OFF” position when coupling or uncoupling personnel only.

hydraulic tools. Failure to do so may result in damage • Make certain that the recommended relief valves

to the quick couplers and cause overheating of the are installed in the pressure side of the system.

hydraulic system.

• Do not use the tool for applications for which it was

• Always store the tool in a clean dry space, safe from not intended.

damage or pilferage.

• Make sure the circuit PRESSURE hose (with male

quick disconnect) is connected to the “IN” port. The

circuit RETURN hose (with female quick disconnect)

is connected to the opposite port. Do not reverse

circuit flow. This can cause damage to internal seals.

• Always replace hoses, couplings and other parts

with replacement parts recommended by STANLEY.

Supply hoses must have a minimum working

pressure rating of 2500 psi/172 bar.

• Do not exceed the rated flow or pressure (refer to

“Specifications” on page 15 for correct flow rate

and pressure). If specifications are exceeded, rapid

failure of the internal seals may result.

TP08 User Manual ◄ 13

TROUBLESHOOTING

If symptoms of poor performance develop, the following chart can be used as a guide to correct the problem.

When diagnosing faults in operation of the tool, always make sure the hydraulic power source is supplying the

correct hydraulic flow and pressure as listed in the table. Use a flowmeter know to be accurate. Check the flow with

the hydraulic fluid temperature at least 80 °F/27 °C.

PROBLEM CAUSE SOLUTION

Pump will not start. No hydraulic fluid flow or Turn on power unit and check that 7–10

pressure. GPM/26-38 LPM at 2000 psi/140 bar is

available at the trash pump.

Defective couplers. Check the couplers by connecting them

together with the hydraulic power supply

operating and with the control valve in the “ON”

position. The power supply should operate

without “loading” from the couplers.

Impeller jammed with debris. Clean the pumping chamber.

Impeller rubbing against wear Check and adjust the impeller clearance.

plates.

Defective power module. Repair or replace the power module.

Poor pump performance. Hydraulic flow reversed. Check that the hoses are correctly connected

to the pump motor ports. The female coupler

should be connected to the “IN” port. The return

fluid must never flow through a reversing valve.

Improper hydraulic fluid flow. Check that 7–10 GPM/26–38 LPM at 2000

psi/140 bar is available at the trash pump.

A 20% decrease in flow can result in a 50%

decrease in pump performance. 8 GPM/30 LPM

is the optimum circuit flow.

Trash pump submersed in Lift the pump from the bottom of the hole or

sediment. chamber. Use a flat support under the pump if

necessary.

Trash pump inlet restricted. Remove restriction and clean thoroughly.

Discharge hose kinked or Straighten the hoes. If the hose must bend at

restricted. the top of the hole, use a piece of split rigid

conduit with large diameter of the expanded

hose. This keeps the hose from kinking. Use a

90° 4-inch pipe elbow on the trash pump outlet

if necessary.

Discharge hose too small. Use a 4-inch diameter fire hose.

Water lift too high. Lower the outlet end of the discharge hose.

Impeller worn or damaged. Check impeller for damage and excessive wear.

Replace if necessary.

Wear plates worn or damaged. Check wear plates for damage and excessive

wear. Replace if necessary.

Hydraulic fluid in discharge Motor shaft seal failure. Replace the motor shaft seal. Ensure power

flow. unit is delivering 7-10 GPM/26-38 LPM

14 ► TP08 User Manual

SPECIFICATIONS

Capacity...................................................................................................................................... 800 GPM/3028 LPM

Weight....................................................................................................................................................59 lbs/26.7 kg

Height (over handle).............................................................................................................................. 16.5 in./42 cm

Length................................................................................................................................................... 19 in./48.3 cm

Width..................................................................................................................................................... 15 in./38.1 cm

Pressure............................................................................................................................................ 2000 psi/140 bar

Flow Range............................................................................................................................. 7–10 GPM/26–38 LPM

Maximum Flow.................................................................................................................................. 10 GPM/38 LPM

Porting.............................................................................................................. #10 SAE (pressure) #12 SAE (return)

Connect Size and Type........................................................... 1/2 in. Male Pipe (pressure) 1/2 in. Male Pipe (return)

Discharge Diameter.................................................................................................................. 4 in./100 mm Camlock

Inlet Diameter.......................................................................................................................................... 4 in./100 mm

ACCESSORIES

Description Part No.

Male Adapter / Female THD 4-8 NPT.................................................................................................................21967

Lay-Flat Discharge Hose Blue, 4 in. × 25 ft with Camlock Fittings.....................................................................65624

MAINTENANCE

Daily As Needed Hours

Grease motor (Item 16, page <?>) with 2 Strokes of

100

Underwater Grease

Volute Intake (Clean) C

Check Fasteners for Tightness I

C Clean.

I Inspect.

CLEANING THE PUMPING CHAMBER

Debris such as weeds, sand and other solids may become trapped in the water hose and pumping chamber.

This can reduce pump performance. It is important that the pumping chamber be kept clean at all times.

The chamber can be cleaned as follows:

1. Remove wear plate by removing the six capscrews.

2. Remove all debris from the volute area.

3. Thoroughly clean the volute and impeller. Do not remove the impeller unless necessary for repair or replace-

ment or to remove trapped debris.

4. Re-assemble and clean the capscrews and lubricate the threads with underwater grease before installation.

5. Remove all debris from the hose. Otherwise, solids will backfill the pump.

TP08 User Manual ◄ 15

TP08 BODY ILLUSTRATION

2

1

6 7 4

8 9

10

11

12

ITEM P/N QTY DESCRIPTION

1 09579 1 Coupler (Model TP08013W)

2 09578 1 Coupler (Model TP08013W)

3 01652 2 Hose (Model TP08013W)

4 82533 1 Fitting (Model TP08013W)

5 82532 1 Fitting (Model TP08013W)

6 03976 1 Male Coupler

7 03975 1 Female Coupler

8 06264 1 Adapter

9 07882 1 Adapter

10 81261 6 Cap Screw

11 81212 1 Handle

13 12 21967 1 Camlock Coupler

13 81210 1 Volute Foot

14 59074 1 Cap Screw

14

16 ► TP08 User Manual

TP08 IMPELLER ILLUSTRATION

5

6

ITEM P/N QTY DESCRIPTION

1 21987 2 Cap Screw

9

2 21986 3 Cap Screw

3 31505 1 Motor Assembly (See page 18)

4 00600 1 Woodruff Key

10 5 06311 1 V-Ring

6 88864 1 TP08 Sticker

11 82525 1 TP08 Sticker (Model TP08013L11)

7 81132 1 Motor Adapter Plate

8 21978 3 Cap Screw

12 9 81133 3 Spacers

10 81260 1 Wear Plate

11 21989 6 Cap Screw

12 21979 1 Impeller

13

13 21989 6 Cap Screw

14 81260 1 Wear Plate

14 15 82522 1 Volute (Yellow)

82523 1 Volute (Black -Model TP08013B)

16 59074 3 Cap Screw

17 03827 1 Washer

15

18 21988 1 Acorn Nut

16

17

18

TP08 User Manual ◄ 17

TP08 MOTOR ILLUSTRATION

5

6

7

9

10 ITEM P/N QTY DESCRIPTION

1 21987 2 Cap Screw

11 2 21986 3 Cap Screw

3 82595 1 Motor Cap Assembly

4 21982 1 Idler Gear

12 5 21984 1 Idler Shaft

6 19793 1 Bushing

13 7 82602 1 Key

8 21974 1 Drive Gear

9 15385 1 O-ring

10 22065 2 Dowel Pin

11 20672 1 Bearing Carrier

14

12 21971 1 Motor Shaft

13 19793 1 Bushing

16 14 01872 1 O-ring

15

15 20680 1 Bearing Washer

16 08020 1 Thrust Bearing

17 17 26812 1 Retaining Ring

18 18 73064 1 Quad Ring

19 19 73059 1 Seal Carrier

20 21981 1 Seal Anvil

20

21 01220 1 Grease Fitting

21 22 21976 1 Housing

22

23 10793 2 Cap Screw

GA 21983 1 Idler Gear Assembly

23 (Includes Item # 4 and # 6)

18 ► TP08 User Manual

UNDERWATER TOOLS DEPTH GUIDELINE

UNDERWATER MODELS ONLY

OPERATION OVERVIEW

PERCUSSIVE ROTATIONAL

Tools: Breakers, Tools: Grinders,

Do not use hydraulic tools underwater that are not Hammer Drills and Saws, Chain Saws

designated as an “underwater” model, or this will Chipping Hammers

result in damage to the tool.

Max Depth: 1000’

DIVER

Max Depth: 500’ - - Reference hose

limitations due to sizing guide below

For underwater hydraulic tools the

applications are broken down into four accumulator PSI

quadrants depending on type of tool and max (increase 40

method of operation. PSI for every 100’)

Tools: Breakers, Tools: Grinders,

The types of tools are percussive and

rotational, each with different characteristics Hammer Drills and Saws, Chain Saws

allowing for different depth operation. With Chipping Hammers

percussive tools, the nitrogen accumulator Max Depth: 1000’

ROV

PSI must counter the increase in ambient Max Depth: 500’ - - Reference hose

pressure found at lower depths. Since there is limitations due to sizing guide below

a maximum PSI for percussive tools they are accumulator PSI

limited to certain depths. Rotational tools do max (increase 40

not have accumulators and thus are capable

of deeper depths. PSI for every 100’)

The methods are broken into diver operated

or remote operated vehicle (ROV). ROV’s RECOMMENDED HOSE DIAMETERS

can reach lower depths and with an onboard DEPTH (FT) 8 GPM 12 GPM

hydraulic power source that is depth

compensated, can operate hydraulic tools at 100 5/8” 5/8”

depths of thousands of feet. ROV operation 300 3/4” 1”

is still limited to the tool, for example a 600 1” 1”

percussive tool has the same depth limitation

whether ROV or diver operated. 1000 1” 1-1/4”

19 ► TP08 User Manual

STANLEY Infrastructure

6430 SE Lake Road

Portland, Oregon 97222 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyinfrastructure.com

Vous aimerez peut-être aussi

- Premiers Secours: un manuel pratique pour faire face aux urgencesD'EverandPremiers Secours: un manuel pratique pour faire face aux urgencesPas encore d'évaluation

- Hoja Tecnica TP03Document20 pagesHoja Tecnica TP03infoPas encore d'évaluation

- Les assurances de personnes en 60 cas pratiques: Ouvrage pédagogiqueD'EverandLes assurances de personnes en 60 cas pratiques: Ouvrage pédagogiquePas encore d'évaluation

- TP03 User Manual 5-2015 V15Document18 pagesTP03 User Manual 5-2015 V15tubjackiePas encore d'évaluation

- BR87 User Manual 2-2015 V13Document22 pagesBR87 User Manual 2-2015 V13AUDRANPas encore d'évaluation

- GT18B01 - B02 User Manual 5-2016 V17 PDFDocument26 pagesGT18B01 - B02 User Manual 5-2016 V17 PDFADJIMGARPas encore d'évaluation

- MB05 Stanley BreakerDocument34 pagesMB05 Stanley BreakerSerkanAl100% (1)

- MB656 Stanley BreakerDocument34 pagesMB656 Stanley BreakerSerkanAlPas encore d'évaluation

- Hermann Saunier Duval - Accumulo Tampone 40 LitriDocument72 pagesHermann Saunier Duval - Accumulo Tampone 40 Litriabba417Pas encore d'évaluation

- Mode D'emploi Pour L'humidificateur Automatique SIRIO: 1 - Mises en Garde Pour Une Utilisation en Toute Se CuriteDocument12 pagesMode D'emploi Pour L'humidificateur Automatique SIRIO: 1 - Mises en Garde Pour Une Utilisation en Toute Se CuriteDimitri Valdes TchuindjangPas encore d'évaluation

- LYNX ManuelDocument188 pagesLYNX ManuelAlexandre MorelPas encore d'évaluation

- MB156 Stanley BreakerDocument32 pagesMB156 Stanley BreakerSerkanAlPas encore d'évaluation

- Wilo 108215Document46 pagesWilo 108215Mhenni OUFELLAPas encore d'évaluation

- BR45 User Manual 8-2020 Ver20Document12 pagesBR45 User Manual 8-2020 Ver20Matiias PuelloPas encore d'évaluation

- Mode D'emploi Photometer 5010: Robert Riele GMBH & Co KGDocument77 pagesMode D'emploi Photometer 5010: Robert Riele GMBH & Co KGahmed serier abdelouahabPas encore d'évaluation

- PDF Dossier Tech Paletticc TSX 37Document134 pagesPDF Dossier Tech Paletticc TSX 37youri59490100% (1)

- Manual Operação Precison Cut 500 PTDocument18 pagesManual Operação Precison Cut 500 PTCJCONSTANTEPas encore d'évaluation

- 2022class Iia Bracket Ascend SL - Rmoe - MDD-MDRDocument2 pages2022class Iia Bracket Ascend SL - Rmoe - MDD-MDRRotaru AndreiPas encore d'évaluation

- An 01 FR Camera - Therm - I7 PDFDocument190 pagesAn 01 FR Camera - Therm - I7 PDFthierryPas encore d'évaluation

- Longe de Harnais Noire Fil Retro Certificat UEDocument3 pagesLonge de Harnais Noire Fil Retro Certificat UEChristophe BessonPas encore d'évaluation

- 2022class Iia Bracket Altitude M-SL - Rmoe - MDD-MDRDocument3 pages2022class Iia Bracket Altitude M-SL - Rmoe - MDD-MDRRotaru AndreiPas encore d'évaluation

- Manual - Balanza 047 CC15NDocument44 pagesManual - Balanza 047 CC15NAndry MolinaPas encore d'évaluation

- Defender 3000 T31 D31 ManuelDocument54 pagesDefender 3000 T31 D31 ManuelDIMITRIC BOGDOLPas encore d'évaluation

- 4-Series IFU FR 1498753-47 PDFDocument74 pages4-Series IFU FR 1498753-47 PDFFrancisth ZeusPas encore d'évaluation

- Manuel Installation Eclairage OperatoireDocument20 pagesManuel Installation Eclairage OperatoireMaxence KouessiPas encore d'évaluation

- MLII RCUII EXL Installation Guide FRDocument92 pagesMLII RCUII EXL Installation Guide FRXavier Enrique Barraza RíosPas encore d'évaluation

- Manuel D Utilisation Vitus15sci Mu Ac-200728-02-Vers01Document22 pagesManuel D Utilisation Vitus15sci Mu Ac-200728-02-Vers01Yoan RodriguezPas encore d'évaluation

- DT PaletticDocument136 pagesDT PaletticMohamed BelaounPas encore d'évaluation

- Communication: RéférenceDocument21 pagesCommunication: RéférenceNeven GvozdAnovićPas encore d'évaluation

- FR 13534 Holmatro CatalogueDocument140 pagesFR 13534 Holmatro CatalogueLoic FerlandaPas encore d'évaluation

- Technical Notice OXAN VULCAN Europe 1Document11 pagesTechnical Notice OXAN VULCAN Europe 1Julio SalazarPas encore d'évaluation

- Variateur Scheider Atv12h055m2 BBV28580Document131 pagesVariateur Scheider Atv12h055m2 BBV28580SAMIR BEL HADJ HMIDAPas encore d'évaluation

- CM20210604 97a8a 654ebDocument24 pagesCM20210604 97a8a 654ebŞadCherietŞıkPas encore d'évaluation

- FM3 Manual-FRDocument129 pagesFM3 Manual-FRQuentin MaumePas encore d'évaluation

- Manuel D'utilisation: BC-5380 Automate D'hématologieDocument600 pagesManuel D'utilisation: BC-5380 Automate D'hématologieMarcelo Brito100% (1)

- Technical Notice Locking Carabiners 1Document14 pagesTechnical Notice Locking Carabiners 1sieteb9876Pas encore d'évaluation

- Manuel de Maintenance APNA-370 Version 2.3Document74 pagesManuel de Maintenance APNA-370 Version 2.3faicalPas encore d'évaluation

- 2022class Iia Wires Rmoe MDD-MDRDocument2 pages2022class Iia Wires Rmoe MDD-MDRRotaru AndreiPas encore d'évaluation

- Manuel Instruc Hcr1000 FRDocument300 pagesManuel Instruc Hcr1000 FRTHONYPas encore d'évaluation

- PLC Exd Atex EnclosureDocument8 pagesPLC Exd Atex EnclosureKHANNNPas encore d'évaluation

- DELTA PLUS GROUP - Déclaration de Conformité DT117XGDocument2 pagesDELTA PLUS GROUP - Déclaration de Conformité DT117XG54r4p2ckbmPas encore d'évaluation

- Manuel Francais H264Document57 pagesManuel Francais H264nouroudine52611Pas encore d'évaluation

- NotcompDocument29 pagesNotcompxxxPas encore d'évaluation

- Access Control Terminal: User ManualDocument24 pagesAccess Control Terminal: User ManualdsfdsPas encore d'évaluation

- Machines Et Installations Industrielles. Sécurité. Conditions de Travail. Spécifications TechniquesDocument54 pagesMachines Et Installations Industrielles. Sécurité. Conditions de Travail. Spécifications TechniquesWilson CarreiraPas encore d'évaluation

- AK1555-B DRX-MobileRet UserGuide FRDocument46 pagesAK1555-B DRX-MobileRet UserGuide FRibrahima baldePas encore d'évaluation

- Adf 2023Document44 pagesAdf 2023Fredwash RichardPas encore d'évaluation

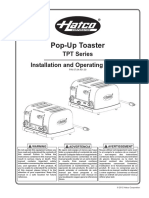

- Hatco Pop-Up Toaster ManualDocument12 pagesHatco Pop-Up Toaster ManualdigitaltextPas encore d'évaluation

- Notice Bracelet ConnectéDocument20 pagesNotice Bracelet ConnectéIdriss OSSENI ASSANIPas encore d'évaluation

- Turbo F7 F9Document43 pagesTurbo F7 F9حمدي العامريPas encore d'évaluation

- Cámara Fotos Sony DSC-RX100M4Document88 pagesCámara Fotos Sony DSC-RX100M4antonioPas encore d'évaluation

- Système de Contrôle - Variateur de Translation PDFDocument21 pagesSystème de Contrôle - Variateur de Translation PDFBoujemaa EL QAISSOUMI100% (1)

- Mindray BS 120 130 180 190 Analyzer Service Manual (001 035)Document318 pagesMindray BS 120 130 180 190 Analyzer Service Manual (001 035)zaoual abdelatif50% (2)

- PM InstructionDocument135 pagesPM InstructionCesar VenturaPas encore d'évaluation

- PTD DocorkafrDocument20 pagesPTD DocorkafrJOhnPas encore d'évaluation

- Automate de La Centrale A BetonDocument13 pagesAutomate de La Centrale A BetonKeita Abraham KalilPas encore d'évaluation

- CBM and MSO 1300 Series (V3 and E3) - CB CertificateDocument2 pagesCBM and MSO 1300 Series (V3 and E3) - CB CertificateAlbeiro buendia diagoPas encore d'évaluation

- Certificacion Tapon Silicona DaumerDocument1 pageCertificacion Tapon Silicona DaumerteefiihPas encore d'évaluation

- 2022class I ProtectionWaxes RMOE MDD-MDRDocument1 page2022class I ProtectionWaxes RMOE MDD-MDRRotaru AndreiPas encore d'évaluation

- 317L 16 - Chauvin (Screen)Document64 pages317L 16 - Chauvin (Screen)Mohamed HardmanPas encore d'évaluation

- Les Produits D EntretienDocument3 pagesLes Produits D EntretienSandrine CharinPas encore d'évaluation

- La Motivation Des Élèves de Formation ProfessionnelleDocument22 pagesLa Motivation Des Élèves de Formation ProfessionnelleOlsen MalagaPas encore d'évaluation

- Théorie Des MachinesDocument20 pagesThéorie Des MachinesJeanne Varenne EmvutouPas encore d'évaluation

- NXO 5v7ds7NU PDFDocument69 pagesNXO 5v7ds7NU PDFChristophe GarnierPas encore d'évaluation

- Cours 4 Introduction À La Génomique 2021Document10 pagesCours 4 Introduction À La Génomique 2021fsxnsstoaehkbhlzygPas encore d'évaluation

- JumiaDocument3 pagesJumiakhalidPas encore d'évaluation

- Plastiques TechniquesDocument1 pagePlastiques Techniquesbagueneau YOUTUBEPas encore d'évaluation

- Ystème NerveuxDocument4 pagesYstème NerveuxRabab Tamouh0% (1)

- Ingénierie - Le Cycle en VDocument3 pagesIngénierie - Le Cycle en VbommobPas encore d'évaluation

- La Création de ValeurDocument68 pagesLa Création de Valeursene seydina mouhamedPas encore d'évaluation

- Osp 1168-35-4 La Notion de Projet en Psychologie de L OrientationDocument13 pagesOsp 1168-35-4 La Notion de Projet en Psychologie de L OrientationMus OubPas encore d'évaluation

- Pont Mixte FINALDocument26 pagesPont Mixte FINALĐíßMohammedRiadPas encore d'évaluation

- Cours No 10-Ostèologie (Suite)Document7 pagesCours No 10-Ostèologie (Suite)Feriel FerielPas encore d'évaluation

- Finances Publiques - Raya ChoubaniDocument37 pagesFinances Publiques - Raya Choubaniمنير بعكةPas encore d'évaluation

- Fonction Convertir Machines Synchrones Triphases CoursDocument5 pagesFonction Convertir Machines Synchrones Triphases CoursdddddPas encore d'évaluation

- 425 914 1 SMDocument10 pages425 914 1 SMkami ouachemPas encore d'évaluation

- Fiche ROME BrasseurDocument5 pagesFiche ROME BrasseuryannplmrPas encore d'évaluation

- Exercices Is LM BPDocument6 pagesExercices Is LM BPDachka Ridore100% (1)

- Sujet 2022Document4 pagesSujet 2022baha brahmiPas encore d'évaluation

- 2les NavigateursDocument2 pages2les NavigateursImane TlmPas encore d'évaluation

- Exposé Réorganisation Du CapitalfinalDocument30 pagesExposé Réorganisation Du CapitalfinalAdil BentalebPas encore d'évaluation

- Colle 02Document2 pagesColle 02Hamed TraorePas encore d'évaluation

- Registre D'élevage Gratuit Plateforme Du MielDocument12 pagesRegistre D'élevage Gratuit Plateforme Du Mielmas.eric34Pas encore d'évaluation

- Convention PFE EntrepriseenTunisieDocument3 pagesConvention PFE EntrepriseenTunisieChaima BelhediPas encore d'évaluation

- Projet PFE01Document127 pagesProjet PFE01soukaPas encore d'évaluation

- Le Marketing Digital Pour Les NulsDocument453 pagesLe Marketing Digital Pour Les NulsAMINEPas encore d'évaluation

- Cps TraverséDocument77 pagesCps TraverséYoussefChariPas encore d'évaluation

- Antoche 1497Document21 pagesAntoche 1497Flynders PetryePas encore d'évaluation

- PédopsyDocument3 pagesPédopsyTASMINE HAMZAPas encore d'évaluation

- Trading Price Action TRENDSDocument53 pagesTrading Price Action TRENDSKOUASSI KOFFI JEAN DE CAPISTRANPas encore d'évaluation