Académique Documents

Professionnel Documents

Culture Documents

BR45 User Manual 8-2020 Ver20

Transféré par

Matiias PuelloCopyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

BR45 User Manual 8-2020 Ver20

Transféré par

Matiias PuelloDroits d'auteur :

Formats disponibles

Infrastructure

Safety, Operation & Maintenance

BR45 Hydraulic Breaker

81140 User Manual 8/2020 Ver. 20

DECLARATION OF CONFORMITY

ÜBEREINSTIMMUNGS-ERKLARUNG

DECLARATION DE CONFORMITE CEE

DECLARACION DE CONFORMIDAD

DICHIARAZIONE DI CONFORMITA

______________________________________________________________________

I, the undersigned:

Ich, der Unterzeichnende:

Nuerenberg, David

Je soussigné: Surname and First names/Familiennname und Vornamen/Nom et prénom/Nombre y apellido/Cognome e nome

El abajo firmante:

lo sottoscritto:

hereby declare that the equipment specified hereunder:

bestätige hiermit, daß erklaren Produkt genannten Werk oder Gerät:

déclare que l’équipement visé ci-dessous:

Por la presente declaro que el equipo se especifica a continuación:

Dichiaro che le apparecchiature specificate di seguito:

1. Category: Hydraulic Hand-Held Concrete Breaker

Kategorie:

Catégorie:

Categoria:

Categoria:

2. Make/Marke/Marque/Marca/Marca STANLEY

3. Type/Typ/Type/Tipo/Tipo: BR4514801, BR4516801, BR4516807, BR4516807A

BR4514801A, BR4556801, (BR45350 – For Underwater Use Only)

4. Serial number of equipment: BR4514801 All

Seriennummer des Geräts:

Numéro de série de l’équipement:

BR4514801A All

Numero de serie del equipo: BR4516801 All

Matricola dell´attrezzatura: BR4516807 All

BR4516807A All

BR4556801 All

BR45350 Serial # 030612029 and above

(For Underwater Use Only)

5. Mass/Masse/Masse/Masa/Massa 23 kg

Has been manufactured in conformity with

Wurde hergestellt in Übereinstimmung mit

Est fabriqué conformément

Ha sido fabricado de acuerdo con

E’ stata costruita in conformitá con

Directive/Standards No. Approved body

Richtlinie/Standards Nr Prüfung durch

Directives/Normes Numéro Organisme agréé

Directriz/Los Normas No Aprobado

Direttiva/Norme n. Collaudato

EN ISO 28927-10 Self

EN ISO 3744 (15744) AkustikNet (Notified body ID 1585)

Bagsvard Hovedgade 141, 2880 Bagsvard, Denmark

Certificate #863/2011/002 (Verification 2015-08-04) Valid: 12/31/2018

EN ISO 11148-4 Self

EN ISO 13732-1 Self

Machinery Directive 2006/42/EC:2006 Self

6. Special Provisions: None 7. Measurements: Measured Sound Power Level 105 LwA

Spezielle Bestimmungen: Messungen Guaranteed Sound Power Level 107 LwA

Dispositions particulières: Mesures Measured in accordance to Directive 2000/14/EC,

Provisiones especiales: Mediciones Annex III, Part B, No 10, 15 kg<m< 30 kg

Disposizioni speciali: Misurazioni

8. Representative in the Union: Patrick Vervier, Stanley Dubuis 17-19, rue Jules Berthonneau-BP 3406 41034 Blois Cedex, France.

Vertreter in der Union/Représentant dans l’union/Representante en la Union/Rappresentante presso l’Unione

Done at/Ort/Fait à/Dado en/Fatto a STANLEY Infrastructure, Milwaukie, Oregon USA Date/Datum/le/Fecha/Data 4-26-2018

Signature/Unterschrift/Signature/Firma/Firma

Position/Position/Fonction/Cargo/Posizione North America Quality Manager

A

7

1

8

6 2

14 9

3

5

10

13

4

11

12

B C

1

4

2

5

3

4

D

1

4

6

2

(a)

(b)

8

2 | BR45 User Manual

E

2

3

4

1

5

24 7

6

25

8

26 9

27 23

28 12

10

29 13 11

30 14

15

31

16

18

17

32

22 19

33

21

20

34

BR45 User Manual | 3

F

14 15 1

13 16 2 3

11 12

4b 17

4

4a

10

38 5

8 9

41 39 6

7

40

42

37

18

43

36 19

44 35 20

34

21

33

22

32 23

45

24

31

25

46 30

47

29

28

27 26

48

4 | BR45 User Manual

G

1

2

3

7

11

8 9 10

12 13

H

1

2

3

10

11 12 13 15

14

16

17

18

BR45 User Manual | 5

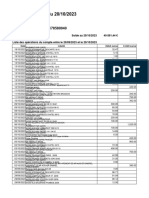

T-Handle Parts Illustration - Detail E Anti-Vibration Parts Illustration - Detail F

ITEM P/N DESCRIPTION ITEM P/N DESCRIPTION

1 04374 Hex Nut 6 20505 Handle Pivot Block

2 04371 Trigger 7 20499 Charge Valve

3 07493 O-ring Plug 8 07493 Plug

4 20499 Charge Valve 9 20500 Roll Pin

5 07492 Roll Pin 10 10180 Caution N2 Gas Sticker

6 02494 Handle Grip 11 58529 Trigger Handle

7 07483 Handle 12 58526 Trigger

8 04056 Rod Wiper* 13 07624 Roll Pin

9 04057 Bushing 14 58527 Trigger Lock

10 00293 O-ring* 15 66828 Torsion Spring

11 01362 O-ring* 16 20511 Lever

12 04077 Valve Spool 17 04374 Hex Nut

13 04058 Compression Spring 18 07699 Bushing Assembly

14 11588 Accumulator Valve Block 19 00293 O-ring*

15 01652 Hose Whip, 12 in. 20 01362 O-ring*

16 03972 Coupler, Female 21 07479 Accumulator Diaphragm

17 03973 Coupler, Male 22 58601 Sound Power Level Sticker

18 74664 Name Tag (8 GPM models) 23 28409 Composite Sticker

74660 Name Tag (5 GPM models) 24 11588 Accumulator Valve Block

74669 Name Tag (Underwater models) 25 20517 Side Rod

19 04373 Side Rod 26 Depends on

Breaker Foot, see detail G & H.

model

20 Depends on

Breaker Foot, see detail G & H. 27 72919 Snap-On Filler

model

21 72919 Snap-On Filler 28 74832 STANLEY Logo Sticker (Black)

22 74832 STANLEY Logo Sticker (Black) 74770 STANLEY Logo Sticker (Yellow)

74770 STANLEY Logo Sticker (Yellow) 29 74663 Name Tag (8 GPM Models)

23 07479 Accumulator Diaphragm 74659 Name Tag (5 GPM Models)

24 04381 Back-up Ring* 30 03973 Coupler, Male

25 04379 O-ring* 31 03972 Coupler, Female

26 04378 Porting Block 32 01652 Hose Whip, 12 in.

27 02900 Roll Pin 56725 Hose Whip, 18 in. (Model BR45158)

28 07480 Automatic Valve Body 66727 Hose Whip (Model BR45158BN)

29 04571 Push Pin 33 11207 Circuit Type “D” Sticker

30 04382 Automatic Valve 34 28322 CE Sticker

31 07481 Piston 35 04058 Compression Coil Spring

12833 Piston (BR45550 Only) 36 20515 Valve Spool

32 04605 Push Pin 37 04056 Rod Wiper*

33 07485 Flow Sleeve 38 04381 Back-up Ring*

34 04383 Flow Sleeve Tube 39 04379 O-ring*

35 04595 Seal Kit (*In seal kit) 40 04378 Porting Block

41 02900 Roll Pin

Anti-Vibration Parts Illustration - Detail F 42 07480 Automatic Valve Body

ITEM P/N DESCRIPTION 43 04571 Push Pin

1 28494 Top Plate 44 04382 Automatic Valve

2 28369 Guarded Handle 45 07481 Piston

3 02494 Handle Grip 12833 Piston (Model BR4556801)

4 20498 Spring 46 04605 Push Pin

4a 20540 Springs - Models BR45125S, BR45135S, 47 07485 Flow Sleeve

4b 20541 BR4513516, BR45158, BR45158BN 48 04383 Flow Sleeve Tube

5 20508 Pivot Screw

6 | BR45 User Manual

Breaker Foot Assembly - Detail G

MODEL

BR4515X,

ITEM DESCRIPTION QTY BR4516X, BR4556801 BR45350 BR4514801 BR45110

BR45550

1 Cup Seal 1 04386

2 Back-up Washer 1 04780

3 Rod Wiper 1 04387

4 O-ring 1 02022

5 Breaker Foot 1 07510 07489 08856 07694 07899

6 Hex Bushing 1 07510 07489 08856 07694 07899

7 Latch 1 04394

8 Hex Nut 1 04374

9 Spring Washer 2 04716

10 Taper Sleeve 2 04715

11 Spring 1 04392

12 Detent 1 04393

13 Latch Bolt 1 04717

Breaker Foot Assembly - Detail H

MODEL

ITEM DESCRIPTION QTY BR45120, BR45120D BR45130 BR45130X, BR45135X BR45120E, BR45125S

1 Cup Seal 1 04386

2 Back-up Washer 1 04780

3 Rod Wiper 1 04387

4 Insert 1 62334 72931 08081 08154

5 O-ring 1 02022

6 Breaker Foot 1 62334 72931 08081 08154

7 Hex Bushing 1 62334 72931 08081 08154

8 Compression Coil 1 --- 81197

9 Spring 2 01744

10 Detent 1 08411

11 Hex Nut 1 04984

12 Spring Washer 2 04985

13 Taper Sleeve 2 01269

14 Latch 1 01837

15 Latch Bolt 1 04983

16 Wear Ring 2 --- 07516

17 Collar Support 1 --- 07520 08115

18 Retaining Ring 1 --- 07522

BR45 User Manual | 7

Safety Precautions • Slips, trips and falls are major causes of workplace injury. Be observant

of hoses or oil surfaces lying about the work area, as they can be a

The Safety Alert Symbol alerts you to potential tripping hazard.

personal injury hazards. Obey all safety messages • Operators must start in a work area without bystanders and must assess

that follow to avoid possible injury or death. the risks to bystanders.

• Keep work area clean and well lit. Cluttered or dark areas invite

Indicates an imminently hazardous situation which

accidents.

will result in death or serious injury.

• Operators must be familiar with all prohibited work areas such as

Indicates a potentially hazardous situation which excessive slopes and dangerous terrain conditions.

could result in death or serious injury • Only use clean hydraulic fluid, filling equipment and lubricants that

Indicates a potentially hazardous situation which have been recommended by STANLEY.

could result in property damage. • Ensure tools are working properly and safely by performing preventative

maintenance (PM) procedures.

Always observe safety symbols. They are included for your safety and for the • Repair and service of this tool must only be performed by an authorized

protection of the tool. and certified dealer.

• Do not force the tool to do the work of a larger tool. Use the correct

WARNING: Read all safety warnings and instructions. Failure tool for your application.

to follow the warnings and instructions may result in tool • Use only hoses and hose couplings that are rated for a minimum

damage and/or serious injury. working pressure of 2500 PSI (172 BAR).

• In spite of the application of relevant safety regulations and the

WARNING: To reduce the risk of injury, read the instruction implementation of safety devices, certain residual risks cannot be

manual. avoided. These risks are: repetitive strain injury due to incorrect posture

and risk of pinching fingers when changing tool bit.

General Dust and Fumes

• Do not discard safety instructions. Give to the operator.

• This tool will provide dependable service if operated in accordance • WARNING: Some dust created by power sanding, sawing, grinding,

with the instructions given in this manual. Read and understand this drilling, and other construction activities contains chemicals known

manual and any stickers and tags attached to the tool and hoses before to the State of California to cause cancer, birth defects or other

operation. Failure to do so could result in personal injury or equipment reproductive harm. Some examples of these chemicals are:

damage. • Lead from lead-based paints,

• Inspect the tool before each use and ensure all decals are legible. • crystalline silica from bricks and cement and other masonry

Contact STANLEY if replacements are needed. products, and

• Establish a training program for all operators to ensure safe operation. • arsenic and chromium from chemically-treated lumber.

Do not operate the tool unless thoroughly trained or under the Your risk from these exposures varies, depending on how often you do this

supervision of an instructor. Keep out of the reach of children. type of work. To reduce your exposure to these chemicals: work in a well

• Operators and maintenance personnel shall be able to physically handle ventilated area, and work with approved safety equipment, such as those

the bulk, weight and power of the tool. dust masks that are specially designed to filter out microscopic particles.

• Avoid unsuitable postures as these positions do not allow for Protect yourself and those around you. Research and understand the

counteracting of normal or unexpected movement of the tool, such as materials you are grinding. Follow correct safety procedures and comply

a sudden break of the tool bit. Change postures during extended tasks with all applicable national, state or provisional health and safety regulations

to help avoid discomfort or fatigue. relating to them, including, if appropriate arranging for the safe disposal of

• Never use the tool unless the inserted tool is retained with a proper the materials by a qualified person.

retainer. • When dust or fumes are created, control them at the point of emission.

• Do not operate a damaged, improperly adjusted, modified or Direct tool exhaust to minimize disturbance of dust.

incompletely assembled tool. • Operate and maintain the tool as recommended in this manual to

• Use and maintain the tool as stated in this manual. Misuse of the tool minimize dust.

can cause serious injury. Do not modify the tool in any way. • Use respiratory protection in accordance with employers instruction or

• Do not operate the tool in explosive atmospheres, such as in the as required by occupational health and safety regulations.

presence of flammable liquids, gases or dust. Power tools create sparks • Avoid prolonged contact with dust. Allowing dust to get into your

which may ignite the dust or fumes. mouth, eyes or lay on the skin may promote absorption of harmful

• Provide adequate ventilation in closed areas when operating a gas or chemicals.

diesel hydraulic power source. PPE

• Do not inspect, carry, clean, change accessories or perform • Always wear safety equipment such as impact resistant goggles, ear

maintenance on the tool while the power source is connected. protection, head protection, breathing protection and safety shoes at all

Accidental engagement of the tool can cause serious injury. times when operating the tool.

• Ensure work piece is securely fixed. Be aware that failure of the work • Hands may be exposed to hazards, impacts, cuts, abrasions and heat.

piece or accessories may generate high velocity projectiles. Wear gloves.

• Never use the tool bit as a hand struck tool. • Wear a hardhat if performing overhead work.

• Stay alert, watch what you are doing and use common sense when • Use PPE that conforms to standards ANSI Z87.1 (Eye and Face

operating a hydraulic tool. Do not operate this tool if you are tired or Protection), ANSI Z89.1 (Head Protection), ANSI Z41.1 (Foot Protection)

under the influence of drugs or alcohol. A moment of inattention while and ANSI S12.6 (S3.19) (Hearing Protection).

operating hydraulic tools may result in serious injury. • Do not wear loose fitting clothing or jewelry when operating the tool.

• During operation, do not contact mechanisms, accessories or hardware

as they can become very hot or sharp; use your Personal Protection

Equipment (PPE).

• Supervising personnel should develop additional precautions relating to

the specific work area and local safety regulations.

• Never operate the tool if you are unsure about the presence of

underground utilities, such as electrical cables, gas pipes, etc. These can M003 M004 M016

cause a hazard if damaged with the tool. Wear Ear Wear Eye Wear a Mask

• The tool is not insulated against coming into contact with electric Protection Protection

power. Use hose certified as non-conductive.

• Do not overreach. Maintain proper footing and balance at all times

when using the tool. Sound

• Exposure to high noise levels can cause permanent, disabling hearing

8 | BR45 User Manual

loss and other problems, such as tinnitus (ringing, buzzing, whistling

or humming in the ears). Use hearing protection in accordance with

employer’s instructions and as required by occupational health and

safety regulations.

• Use and maintain as recommended in the manual to prevent an

unnecessary increase in noise levels.

Vibration

• When using a non-rotary percussive tool to perform work related

activities, the operator can experience discomfort in the hands, arms,

shoulders, neck or other parts of the body.

• If you experience numbness, tingling, pain or whitening of the skin

in your fingers or hands, stop using the tool. Tell your employer and

consult a physician.

• Wear warm clothing when working in cold conditions and keep your

hands warm and dry.

• Exposure to vibration can cause disabling damage to the nerves and

blood supply of the hands and arms.

• Use and maintain as recommended in the manual to prevent an

unnecessary increase in vibration.

• Check for vibration level before each service. If you feel a higher than

normal vibration, contact your STANLEY dealer for repair.

Hydraulic

• Warning: Hydraulic fluid under pressure could cause skin injection

injury. Do not check for leaks with your hands. If you are injured by

hydraulic fluid, get medical attention immediately.

• Do not let hydraulic oil get on the skin. Hydraulic oil is hot. Wear

Personal Protection Equipment (PPE) at all times.

• If exposed to hydraulic fluid, wash hands immediately.

• Do not exceed the maximum relief valve setting stated on the tool.

• Inspect and clean couplers before use, daily. Replace damaged couplers

immediately.

• Hydraulic circuit control valve must be OFF before coupling or

uncoupling tools. Failure to do so may damage the couplers and cause

overheating of the hydraulic system.

• Ensure the couplers are properly connected and are tight.

• Do not operate the tool at fluid temperatures above 140°F (60°C).

Higher temperatures can cause operator discomfort and damage to the

tool.

• Do not exceed the rated flow and pressure as stated on the tool. Rapid

failure of the internal seals may result.

BR45 User Manual | 9

What is the BR45 Hydraulic Breaker? 4 STANLEY Logo Decal

BR45 is a hydraulic breaker for use in the 35-55 lbs. weight class. Designed

for light to medium duty operation, BR45 excels at curb and sidewalk

5 Composite Safety Decal (CE Models)

demolition, asphalt cutting and ground rod driving. BR45 requires an 6 Sound Power Level Decal (CE Models)

external hydraulic power source capable of supplying 7-9 GPM or 4-6 GPM,

7 Trigger Lock

depending on model.

8 Trigger

Specifications

9 CE Decal (CE Models)

Pressure 1500-2500 PSI (103-172 BAR)

10 Circuit Type “D” Decal (CE Models)

Flow 7-9 GPM (26-34 LPM) OR 4-6 GPM (15-22

LPM) 11 Tool Bit Latch

Max. Pressure 2500 PSI (172 BAR) 12 Breaker Foot

Max. Relief Pressure 2150 PSI (148 BAR) 13 Tool Name Tag

Recommended Back 250 PSI (17 BAR) or less 14 Hydraulic Input and Output Ports

Pressure

Couplers 3/8 inch male pipe hose ends, HTMA flush face Tool Setup - Detail B

1. Using a calibrated flow and pressure gauge, check the output of the

Port Size SAE 8 O-ring

hydraulic power source. Ensure it matches the flow and pressure in

Tool Weight T-Handle: 51 Lbs (23 Kg) “Specifications” on page 10. Hydraulic fluid must be 50°F or above.

Anti-vibration: 55 Lbs (25 Kg) Preheat if necessary.

Tool Length T-Handle: 27 inches (69 cm) 2. Ensure that the hydraulic power source is equipped with a relief valve

Anti-vibration: 29 inches (74 cm) set to open at the maximum relief pressure. See”Specifications” on

page 10.

Width (at handles) T-Handle: 14 inches (36 cm)

Anti-vibration: 18 inches (46 cm)

Max. Hydraulic Oil 140°F (60°C)

Temp. Do not install or change tool accessories while the

hydraulic power source is connected. Accidental

HTMA/EHTMA Category Type 2, Category D engagement of the tool can cause serious injury.

Underwater Tool Max. 500 Ft. (Increase accumulator charge by 40 PSI Disconnect the hydraulic power source before installing

Depth per 100 Ft.) or changing accessories.

Recommended Hose Diameters for Underwater Applications

Depth 8 GPM (30 LPM) 12 GPM (45 LPM) 3. Power down the hydraulic power source. Disconnect from the tool.

4. Unlock the breaker foot latch.

100 Feet (31 Meters) 5/8 Inches (16 mm) 5/8 Inches (16 mm) 5. Insert the tool bit and lock the latch. Never use BR45 unless the tool bit

300 Feet (91 Meters) 3/4 Inches (19 mm) 1 Inch (25.4 mm) is locked in the retainer.

Note: Never use a blunt tool bit as they cause more vibration.

600 Feet (183 Meters) 1 Inch (25.4 mm) 1 Inch (25.4 mm) 6. Wipe the hydraulic couplers clean. Connect to the hydraulic power

1000 Feet (305 Meters) 1 Inch (25.4 mm) 1 1/4 Inches (32 mm) source.

7. Power up the hydraulic power source.

Sound & Vibration Declaration

Tool Operation - Detail C

BR45 Anti-vibration Handle

Measured A-Weighted sound power 105 dBA

level

Always hold tool with both hands to maximize control.

Uncertainty 1.7 dBA Apply proper down pressure and maintain proper

Measured A-Weighted Sound Pressure 98 dBA footing at all times.

Uncertainty 3 dBA

1. Wrap your hands around the handles. Stand in back of the tool, using

Values determined according to noise test code given in ISO 15744, using your leg against the snap-on filler for stability.

the basic standard ISO3744. Test conducted by independent notified body Note: Hold the tool correctly and be ready to counteract normal or sudden

to comply with 2000/14/EC:2005. movements. Have both hands available.

Measured Vibration Emission Value: 18.9 m/sec² 2. Place the breaker bit on the material to be broken, at a 90° angle.

3-Axis Apply down pressure.

3. Flip the trigger lock (CE models only).

Uncertainty 2.38 m/sec² 4. Slowly squeeze the trigger to start breaking. Squeeze harder for fast

BR45 T-Handle speed operation.

5. When starting, break until the tool bit breaks through, then reposition

Measured Vibration Emission Value: 19.1 m/sec² the bit. Do not use the tool bit as a lever to move material.

3-Axis Note: Never cool a hot tool bit in water. Tools can become brittle and can fail.

Uncertainty 2.38 m/sec² 6. Continue breaking around the original hole, in 2 inch sized bites.

7. Release Trigger to stop the tool.

Note: If you encounter a breakdown or the tool stops for any reason, release

Parts of a BR45 - Detail A the trigger and power down the hydraulic power source.

1 Handle

2 Gas Under Pressure Decal Tool Maintenance

Use only accessories, consumables and parts recommended by STANLEY.

3 Accumulator Charging Port

Daily Maintenance

10 | BR45 User Manual

1. Remove hydraulic power from the tool and check all hydraulic

connections and hoses for damage. Replace damaged parts before Accessories

operating the tool. 14 in. Chisel, 3 in. wide 07704 5.25 in Clay Spade 07705

2. Inspect the tool bit latch and associated parts. Replace when they have

become worn, cracked or distorted. Asphalt Wedge, 3 in wide 07706 1 in. Lag Bolt Driver 208001

3. Inspect tool to ensure all stickers are legible. Contact STANLEY if 1 in. Lag Bolt Driver 73355 Spike Driver Bit 38709

replacements are needed.

4. Check the flow and pressure of the hydraulic power source using a 5 in. Tie Tamper 29431

calibrated flow meter. Proper flow and pressure maintain proper tool 1 1/8 inch hex x 6 inch shank

speed. If tool speed increases or decreases, stop using the tool and

14 in. Moil Point 02333 14 in. Chisel Point 03990

ensure proper flow and pressure.

14 in. Chisel, 3 in. wide 02334 5 1/2 in. Clay Spade 02331

Accumulator Charge - Detail D

12 in. Asphalt Wedge 08106 5 in. Asphalt Cutter 02332

Check accumulator charge every 6 months or if poor performance develops.

1 in. Ground Rod Driver 04176

Required Tools: 1 1/4 inch hex x 6 inch shank

• STANLEY Accumulator Charge Kit (P/N 31254)

• Nitrogen Bottle 14 in. Moil Point 02336 14 in. Chisel, 3 in. wide 02337

Check 5 1/2 in. Clay Spade 09262 Asphalt Cutter, 5 inch 02335

1. Remove the charging plug from the breaker handle. wide

2. (a) Hold the chuck end of the tester and (b) twist the gauge counter-

clockwise. This will retract the valve stem. 1 in. Ground Rod Driver 04367 1 in. Heavy Duty Chisel 02338

3. Screw the tester onto the breaker charging port. 18 in. Heavy Duty Moil 04404 8 in. Clay Spade 04405

4. Twist the tester gauge clockwise and read the pressure indicated on the Point

gauge. Charge should be 500-700 PSI (34-48 BAR).

Charge Detachable Shank for 17782 Tamping Pad for 17782 17783

5. Retract the tester valve stem. 17783

6. Connect the charging assembly hose to the tester. Troubleshooting

7. Twist the tester gauge clockwise to advance the valve stem.

8. Slowly open the snub valve and charge to 600 PSI (42 BAR). Problem Possible Cause Solution

9. Close the snub valve, retract the tester valve stem and remove the tester Ensure the power

from the breaker charging port. Replace the charging plug. source is delivering

proper flow and

The hydraulic power

Underwater Tool Maintenance source is not running

pressure. See

1. Using a water displacing oil, spray into the trigger slot. “Specifications” on

or not running

2. Spray into the side holes. page 10. Proper

properly.

3. Spray into the breaker foot and remove water from the breaker foot. flow and pressure

4. Spray or dip the rest of the tool. maintain proper tool

speed. Check regularly.

Tool Storage Turn off and

Clean the tool and store in a clean, dry space that is safe from damage. disconnect the tool

Ensure the tool is secured and will not move during transport. An unsecured Couplers or hoses are from the hydraulic

tool could cause injury or damage to the tool. blocked. power source. Inspect

and ensure no

blockage exists.

Tool Disposal Check and recharge

Tool does not run or

Hydraulic Oil runs improperly. accumulator if

Hydraulic oil can contaminate the air, ground and water if not properly Low accumulator necessary. See

recycled. Recycle hydraulic oil in accordance with all State, Federal and local charge. “Accumulator Charge

laws, at your local oil recycling facility. - Detail D” on page

11.

Hydraulic Hoses Provide a cooler to

Hang hydraulic hoses to drain. Collect the oil for recycling. Contact your local maintain proper

Hydraulic fluid is too

municipal recycling authorities for an approved hydraulic hose recycling site. temperature. See

hot.

“Specifications” on

Tool Body page 10.

Drain hydraulic oil from the tool, making sure to collect the oil for recycling.

Check the hydraulic

Discharge the accumulator, disassemble the tool and dispose of all non-metal

High back pressure. system for excessive

parts. Recycle the metal components. Contact your local municipal recycling

back pressure.

authorities for recycling instructions.

Mechanical failure of

Accessories piston or automatic

Contact your STANLEY

dealer for service.

7/8 inch hex x 3 1/4 inch shank valve.

16 in. Clay Spade 02328 14 in. Chisel, 3 in wide 02330 Fluid leakage on tool Lower piston seal Contact your STANLEY

bit. failure. dealer for service.

5 in. Asphalt Cutter, 5 in 02341 18 in. Moil Point 04401

wide Fluid leakage around Contact your STANLEY

Valve spool failure.

the tool trigger. dealer for service.

14 in. Moil Point 05255 .75 in. Rod Driver 05255

1 inch hex x 4 1/4 inch shank

14 in. Moil Point 07702 14 in. Narrow Chisel 07703

Point

BR45 User Manual | 11

STANLEY Infrastructure

6430 SE Lake Road, Portland, Oregon 97222 USA

(503) 659-5660 / Fax (503) 652-1780

www.stanleyinfrastructure.com

© 2014 Stanley Black&Decker, Inc.

New Britain, CT 06053 USA

Vous aimerez peut-être aussi

- BR87 User Manual 2-2015 V13Document22 pagesBR87 User Manual 2-2015 V13AUDRANPas encore d'évaluation

- GT18B01 - B02 User Manual 5-2016 V17 PDFDocument26 pagesGT18B01 - B02 User Manual 5-2016 V17 PDFADJIMGARPas encore d'évaluation

- Hoja Tecnica TP03Document20 pagesHoja Tecnica TP03infoPas encore d'évaluation

- Hoja Tecnica TP08Document20 pagesHoja Tecnica TP08infoPas encore d'évaluation

- Stanley Id07 Impact Drill Wrench User Manual 2 22 Ver 5Document16 pagesStanley Id07 Impact Drill Wrench User Manual 2 22 Ver 5juan manuel rodriguez tobiasPas encore d'évaluation

- 2022class Iia Bracket Altitude M-SL - Rmoe - MDD-MDRDocument3 pages2022class Iia Bracket Altitude M-SL - Rmoe - MDD-MDRRotaru AndreiPas encore d'évaluation

- Not 300029427 001 01Document42 pagesNot 300029427 001 01blablaPas encore d'évaluation

- Fiber 540E IT - FR - 10.21Document80 pagesFiber 540E IT - FR - 10.21LucaPas encore d'évaluation

- KE WMZ Durchflusssensor IMFDocument2 pagesKE WMZ Durchflusssensor IMFZakaria Ait MehdiPas encore d'évaluation

- Aet C073ba0x Newton IntDocument1 pageAet C073ba0x Newton IntyefersonPas encore d'évaluation

- 3.1.1 - Spécifications Techniques Et Fiches Techniques (AAO - F201-2022) Modifié 1du 20220719Document46 pages3.1.1 - Spécifications Techniques Et Fiches Techniques (AAO - F201-2022) Modifié 1du 20220719peace ximenaPas encore d'évaluation

- Ce TGT 100630Document1 pageCe TGT 100630tarek.amirechePas encore d'évaluation

- TP03 User Manual 5-2015 V15Document18 pagesTP03 User Manual 5-2015 V15tubjackiePas encore d'évaluation

- IrisDocument74 pagesIrisPredrag VignjevicPas encore d'évaluation

- Manual - Balanza 047 CC15NDocument44 pagesManual - Balanza 047 CC15NAndry MolinaPas encore d'évaluation

- Defender 3000 T31 D31 ManuelDocument54 pagesDefender 3000 T31 D31 ManuelDIMITRIC BOGDOLPas encore d'évaluation

- SE EC Declaration of Conformity Fronius Symo 10.0-3-M-OS 20.0-3-M MultiDocument10 pagesSE EC Declaration of Conformity Fronius Symo 10.0-3-M-OS 20.0-3-M MultibigmauPas encore d'évaluation

- conformidadMTKD S1Document2 pagesconformidadMTKD S1Jair VillaverdePas encore d'évaluation

- Prisma G - 04404Document3 pagesPrisma G - 04404kevin essanePas encore d'évaluation

- SE EC Declaration of Conformity Symo GEN24 10kW MultiDocument10 pagesSE EC Declaration of Conformity Symo GEN24 10kW MultiRadu Paul SorinPas encore d'évaluation

- 2022class Iia Bracket Ascend SL - Rmoe - MDD-MDRDocument2 pages2022class Iia Bracket Ascend SL - Rmoe - MDD-MDRRotaru AndreiPas encore d'évaluation

- Adf 2023Document44 pagesAdf 2023Fredwash RichardPas encore d'évaluation

- Ventis PRO5Document1 pageVentis PRO53A CompanyPas encore d'évaluation

- Manual Rotina 380RDocument134 pagesManual Rotina 380RMónica LedesmaPas encore d'évaluation

- BruleurDocument80 pagesBruleurDouhaDallouletMajdiPas encore d'évaluation

- 4001139210-Hs15e - Hs15e Pro - Hs18e - Hs18e Pro - E10.22 - Light PDFDocument455 pages4001139210-Hs15e - Hs15e Pro - Hs18e - Hs18e Pro - E10.22 - Light PDFjavimorosPas encore d'évaluation

- 2 - Zodiac Certif NF PAC - Zodiac - Pool - Care - zs500Document3 pages2 - Zodiac Certif NF PAC - Zodiac - Pool - Care - zs500Miguel Angel GilPas encore d'évaluation

- Option Compatible With The Following Machines Option Kompatibel Mit Folgenden GerätenDocument60 pagesOption Compatible With The Following Machines Option Kompatibel Mit Folgenden GerätenOswaldo Aldair Peña CantePas encore d'évaluation

- 2022class Iia Wires Rmoe MDD-MDRDocument2 pages2022class Iia Wires Rmoe MDD-MDRRotaru AndreiPas encore d'évaluation

- BD 8vsDocument38 pagesBD 8vsMarcosPas encore d'évaluation

- RyderDocument60 pagesRyderNicoleta CosteaPas encore d'évaluation

- S200a516i Robox Evo Itagbfradespa PDFDocument46 pagesS200a516i Robox Evo Itagbfradespa PDFAmilcar Quispe Saire100% (1)

- PrimeR 60 - BV CertificatDocument1 pagePrimeR 60 - BV Certificata.rakmanePas encore d'évaluation

- Aet As30s 150kgDocument1 pageAet As30s 150kgMink KhoaPas encore d'évaluation

- Manual de Mantenimiento P1000, 2000 y 3000Document112 pagesManual de Mantenimiento P1000, 2000 y 3000hiram avilaPas encore d'évaluation

- Proces Verbal D'Epreuve Hydrostatique Hydrostatic Test ReportDocument2 pagesProces Verbal D'Epreuve Hydrostatique Hydrostatic Test ReportZarai MaherPas encore d'évaluation

- (00A) Manual - 0307517 - Total - FR - Bouleuse Diviseuse REX FUTURA MULTIDocument210 pages(00A) Manual - 0307517 - Total - FR - Bouleuse Diviseuse REX FUTURA MULTIj.benoist.minestechPas encore d'évaluation

- Wall Air 36 0204 FDocument81 pagesWall Air 36 0204 Fmoumen BoughraraPas encore d'évaluation

- FT Europharmat - GAMMA 3Document8 pagesFT Europharmat - GAMMA 3hccolmar copilotePas encore d'évaluation

- Turbo F7 F9Document43 pagesTurbo F7 F9حمدي العامريPas encore d'évaluation

- Notice Atlantic HygrolixDocument6 pagesNotice Atlantic HygrolixNicolas BédouinPas encore d'évaluation

- DECLARATION Effectuée Par RDURAND: AVIS #11301047 Non CloturéDocument2 pagesDECLARATION Effectuée Par RDURAND: AVIS #11301047 Non CloturéRenaud DurandPas encore d'évaluation

- MF8400 Instruction PDFDocument160 pagesMF8400 Instruction PDFmaquqy100% (1)

- FDS ECB ECR60 ECR65 ECR69 ECR70 Juillet 2014Document14 pagesFDS ECB ECR60 ECR65 ECR69 ECR70 Juillet 2014abdelPas encore d'évaluation

- CO 086 15 OL - RLO01445 - En+frDocument324 pagesCO 086 15 OL - RLO01445 - En+frOmarAnabiPas encore d'évaluation

- Ccpu Et Liste de Colisage: +C E235 51x2,5 51x46 4224 0Document1 pageCcpu Et Liste de Colisage: +C E235 51x2,5 51x46 4224 0moezPas encore d'évaluation

- Operation Manual Machine APR3020, APR3520 Honda 2-00002021Document132 pagesOperation Manual Machine APR3020, APR3520 Honda 2-00002021Milan HájekPas encore d'évaluation

- CE-EP-140+150 FOPS-ROPS P150E Cabine Étroite SIAC (Signés JLD 18-02-2021) para Equipos 33Document2 pagesCE-EP-140+150 FOPS-ROPS P150E Cabine Étroite SIAC (Signés JLD 18-02-2021) para Equipos 33abeldbgPas encore d'évaluation

- Certificat Attestation de Conformite Sanitaire Pehd Agro HydDocument1 pageCertificat Attestation de Conformite Sanitaire Pehd Agro Hydrozalarbi94Pas encore d'évaluation

- AG922 FR Dop E06 0106 10Document1 pageAG922 FR Dop E06 0106 10AZERTYUIOPPas encore d'évaluation

- Relé de Chama Krom SchroderDocument10 pagesRelé de Chama Krom SchroderjeysonsaPas encore d'évaluation

- mx6 With Optional Sampling Pump - EfDocument1 pagemx6 With Optional Sampling Pump - EfAuxiliar SST COMINESAPas encore d'évaluation

- UKCA-Declaration-C069AAXX-SEQUOIA-C069BAXX-SEQUOIA SRTDocument2 pagesUKCA-Declaration-C069AAXX-SEQUOIA-C069BAXX-SEQUOIA SRTyefersonPas encore d'évaluation

- Equipements À Envoyer Pour CertificationDocument8 pagesEquipements À Envoyer Pour Certificationmdrabo89Pas encore d'évaluation

- Cer Rob078Document3 pagesCer Rob078MORELLI silvioPas encore d'évaluation

- M35586FR1Document12 pagesM35586FR1bolawaliPas encore d'évaluation

- Mode D'emploi Pour L'humidificateur Automatique SIRIO: 1 - Mises en Garde Pour Une Utilisation en Toute Se CuriteDocument12 pagesMode D'emploi Pour L'humidificateur Automatique SIRIO: 1 - Mises en Garde Pour Une Utilisation en Toute Se CuriteDimitri Valdes TchuindjangPas encore d'évaluation

- 04.gas - 3 4 5 6 7 - 2 - 2915916 7Document52 pages04.gas - 3 4 5 6 7 - 2 - 2915916 7arkawirawan metodiusPas encore d'évaluation

- Belle RPC 30-50 ManualDocument204 pagesBelle RPC 30-50 ManualKris topherPas encore d'évaluation

- Fairre Les Courses Comprehension Ecrite Texte Questions Comprehension - 99600Document3 pagesFairre Les Courses Comprehension Ecrite Texte Questions Comprehension - 99600Souissi KhayelPas encore d'évaluation

- L'approvisionnement-Logistique-Stock 22Document5 pagesL'approvisionnement-Logistique-Stock 22manar ilhamiPas encore d'évaluation

- Distribution Cours Mmlog10Document37 pagesDistribution Cours Mmlog10Walae AmPas encore d'évaluation

- INTRODUCTION FinalDocument10 pagesINTRODUCTION FinalJose IgnangaPas encore d'évaluation

- Article 1: Les Défis Logistiques de MONOPRIX (2005)Document7 pagesArticle 1: Les Défis Logistiques de MONOPRIX (2005)malak yaPas encore d'évaluation

- Etude Cas Néscafe Carfourre Trade MarketingDocument3 pagesEtude Cas Néscafe Carfourre Trade Marketingchaimaa.manPas encore d'évaluation

- Chap Vi Gescom Iii&ivDocument8 pagesChap Vi Gescom Iii&ivlesagePas encore d'évaluation

- PDF HZP14 - WebDocument40 pagesPDF HZP14 - WebPierre DieuzeidePas encore d'évaluation

- Terminologies LogistiqueDocument4 pagesTerminologies LogistiqueKaimbacamara100% (1)

- Support 1 Cours Distribution Et Merchandising B1 ALTDocument85 pagesSupport 1 Cours Distribution Et Merchandising B1 ALTtmstore.contact.fr100% (1)

- Rapport de StageDocument17 pagesRapport de StageImane ZaidiPas encore d'évaluation

- Rapport de Stage Flo MonsefDocument15 pagesRapport de Stage Flo MonsefIMADE AITHAMMOUPas encore d'évaluation

- Contrat de Vente Fonds de CommerceDocument3 pagesContrat de Vente Fonds de CommerceHACHS MA100% (3)

- Les Études Intérieures 1 PDFDocument8 pagesLes Études Intérieures 1 PDFⵜⴰⴽⴱⴰⵢⵍⵉⵜ ⵜⴰⵀⵓⵔⵉⵜPas encore d'évaluation

- 89a-Fiche Techniques Agricole (Commercialisation Des Produits Locaux)Document3 pages89a-Fiche Techniques Agricole (Commercialisation Des Produits Locaux)Hector-le-troyenPas encore d'évaluation

- Kerty Gurel-54bb6c30Document5 pagesKerty Gurel-54bb6c30tremblayalex546Pas encore d'évaluation

- Enoncé Cas SéphoraDocument8 pagesEnoncé Cas SéphoraHaiyan YUPas encore d'évaluation

- Proposition EFM Merchandising 2023Document2 pagesProposition EFM Merchandising 2023titobimo1996Pas encore d'évaluation

- Marjane DiagDocument48 pagesMarjane DiagImane EmyPas encore d'évaluation

- Distribution Electoménager Et ElectroniqueDocument249 pagesDistribution Electoménager Et ElectroniqueArthur OdinPas encore d'évaluation

- GUC - Bloc 2.3 - MerchandisingDocument2 pagesGUC - Bloc 2.3 - MerchandisingEDLINGERPas encore d'évaluation

- Ca20231020 190046Document2 pagesCa20231020 190046regisherault86Pas encore d'évaluation

- TD Merchandising NewDocument5 pagesTD Merchandising NewAude FangangPas encore d'évaluation

- Dialogues A1Document7 pagesDialogues A1SofiaProfPas encore d'évaluation

- Thème: L'Architecture Commerciale En: Algerie Entre Conception Et RealisationDocument72 pagesThème: L'Architecture Commerciale En: Algerie Entre Conception Et RealisationMarzia ChPas encore d'évaluation

- Quotidien N°3388Document64 pagesQuotidien N°3388SAWADOGO ArmandPas encore d'évaluation

- 18 08 2022.62fdefdc13c1eDocument2 pages18 08 2022.62fdefdc13c1eCsc Soins Corporels Assirem100% (1)

- RemaxDocument10 pagesRemaxChayma RbPas encore d'évaluation

- c3 Le Plan de Marcheage ELE 2020Document71 pagesc3 Le Plan de Marcheage ELE 2020YOYO neufsepttroisdeuxPas encore d'évaluation

- Résumé Marketing PDFDocument6 pagesRésumé Marketing PDFME CISSÉPas encore d'évaluation