Académique Documents

Professionnel Documents

Culture Documents

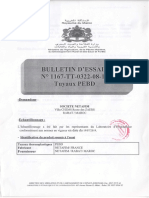

00011687

Transféré par

Mehdi FarrokhiTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

00011687

Transféré par

Mehdi FarrokhiDroits d'auteur :

Formats disponibles

Measuring the rheological properties of bituminous

binders final results from the round robin test of the

BNPÉ/P04/GE1 Working Group (France)

Bernard Eckmann, Sabine Largeaud, Didier Chabert, G Durand, M Robert, R

Van Rooijen, Emmanuel Chailleux, Virginie Mouillet, H Soenen, Norbert

Clavel, et al.

To cite this version:

Bernard Eckmann, Sabine Largeaud, Didier Chabert, G Durand, M Robert, et al.. Measuring the rhe-

ological properties of bituminous binders final results from the round robin test of the BNPÉ/P04/GE1

Working Group (France). 5th Eurasphalt

Eurobitume Congress, Jun 2012, Turkey. 12p, 2012. <hal-00850810>

HAL Id: hal-00850810

https://hal.archives-ouvertes.fr/hal-00850810

Submitted on 8 Aug 2013

HAL is a multi-disciplinary open access L’archive ouverte pluridisciplinaire HAL, est

archive for the deposit and dissemination of sci- destinée au dépôt et à la diffusion de documents

entific research documents, whether they are pub- scientifiques de niveau recherche, publiés ou non,

lished or not. The documents may come from émanant des établissements d’enseignement et de

teaching and research institutions in France or recherche français ou étrangers, des laboratoires

abroad, or from public or private research centers. publics ou privés.

A5EE-157

MEASURING THE RHEOLOGICAL PROPERTIES OF BITUMINOUS BINDERS

FINAL RESULTS FROM THE ROUND ROBIN TEST OF THE BNPÉ/P04/GE1

WORKING GROUP (FRANCE)

B. Eckmann 1, S. Largeaud 2, D. Chabert 3, G. Durand/M. Robert 4, R. Van Rooijen 5, E. Chailleux 6, V. Mouillet 7,

H. Soenen 8, N. Clavel 9, L. Lapalu 10

1

EUROVIA, Direction Technique, 18, place de l’Europe, 92565 Rueil-Malmaison Cedex, France,

bernard.eckmann@eurovia.com

2

EUROVIA, Centre de Recherche de Mérignac,2, rue Thierry Sabine, BP 67, 33703 MERIGNAC Cedex, France,

sabine.largeaud@eurovia.com

3

EIFFAGE Travaux Publics, Centre d'études et de recherches, 8, rue du Dauphiné, 69960 Corbas Cedex, France,

didier.chabert@eiffage.com

4

COLAS, Direction Technique de la Recherche et du Développement, Campus Scientifique et Technique, 4, rue Jean

Mermoz, Bât. A, 78772 Magny les Hameaux, France, durand@campus.colas.fr, robert@campus.colas.fr

5

BP EUROPA SE, GFT BIT-FORM, Pawiker Strasse 30, 45896 Gelsenkirchen, Germany, ronald.vanrooijen@bpge.de

6

IFSTTAR Nantes, Route de Bouaye, BP 4129, 44341 Bouguenais Cedex, France, emmanuel.chailleux@ifsttar.fr

7

LRPC Aix en Provence, CETE Méditerranée, CS 70499, 13593 Aix-en-Provence Cedex 3, France,

virginie.mouillet@developpement-durable.gouv.fr

8

NYNAS NV, Product Technology, Noorderlaan 183, BE-2030 Antwerpen Belgium, hilde.soenen@nynas.com

9

SHELL Bitumen, Société des Pétroles Shell, Immeuble « Les Portes de la Défense », 307 rue Estienne d’Orves, 92708

Colombes Cedex, France, norbert.clavel@shell.com

10

Centre de Recherches TOTAL, Chemin du canal, BP 22, 69360 Solaize, France, laurence.lapalu@total.com

ABSTRACT

In a previous paper presented at the 2008 E&E Congress, the French mirror group (BNPé/P04/GE1) of the

CEN/TC336 – WG1 committee (bituminous binder) has reported the results of a round robin test on DSR complex

modulus measurements involving two paving grade bitumen (10/20 and 50/70 classes) and three modified binders

(plastomer, elastomer and cross-linked elastomer). This paper presents the outcome of the follow-up studies which had

been decided at the time. In a first step, a number of dedicated investigations have been made to identify the potential

contribution of different factors to the variation in measurement results. In particular, the impact of waiting time after

test sample preparation, gap setting procedure, bonding temperature, conditioning times and temperature sweep

procedure have been investigated. How to establish the limits of the linear domain of visco-elasticity is another issue

which has been dealt with. This has allowed to define more stringent operating conditions which have then been

followed by the participating laboratories for a final round robin limited to a pure bitumen (50/70) and the “most

difficult” PmB (high level of plastomer modified product). In comparison to the first round robin, reproducibility was

indeed improved, even for the modified product. The BNPé/P04/GE1 work does thus further open the way for the

definition of binder performance indicators based on DSR measurements. This will however only be possible (especially

for modified binders) if operating conditions are strictly defined and followed.

Keywords : Complex Modulus, Polymer Modified Bitumen, Standardisation, Testing

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

1. INTRODUCTION

In 2003, the French mirror group of WG1 of the CEN TC336 committee (bituminous) had launched an extensive round

robin test on the determination of the dynamic stiffness modulus of bituminous binders. Ten laboratories had been

involved in a program which dealt with 5 types of binders (2 penetration grade bitumen and 3 modified binders). The

equipment used mainly consisted in parallel plate “DSR” rheometers (European standard EN 14770) but the study also

involved apparatus applying an oscillating linear loading, either in a tension-compression (TC) mode on cylindrical

beams at low temperatures, or in an annular shear (AS) mode on samples poured in a cylindrical beaker (French

standard NF T66-065). This study has been reported at the 2008 E&E Congress [1]. It confirmed earlier precision

results on the determination of dynamic stiffness modulus and phase angle with “DSR” equipment [2] but also

highlighted quite poor reproducibility in the case of certain polymer modified binders. This was more particularly the

case for highly “plastomer” modified binders, at low frequencies and at test temperatures in the range going from 30°C

to 50°C. These results had motivated GE1 to continue its investigations so as to find out possible ways of improving

this situation. The outcome of these studies, which led to a new round robin test program, are the subject of this paper.

2. TEST PROGRAM

In a first step, a standard polydiméthylsiloxane (PDMS) reference product (PSTTD 1000VE 9696 by Anton Paar) has

been used to evidence possible systematic off-sets between the various used equipments.

In a second step, focused on parallel plate rheometers, a number of small investigations have been conducted so as to

quantify the potential impact of certain test parameters on the precision of test results. This work has been split between

the different participating laboratories and essentially conducted on two binders already used for the first round robin

test [1], i.e. a straight-run pure bitumen (50/70 pen. grade) and/or the “plastomer” polymer modified binder (referred to

as “PmB2”). The investigated parameters are listed hereafter.

- Waiting time (at ambient temperature) between the casting of the binder sample and the start of the test

procedure (only molded specimen have been used).

- Bonding temperature when loading the test sample onto the rheometer.

- Test preparation after loading the sample : “zero gap” temperature, sample trimming, gap setting.

- Thermal history of the sample once mounted on the rheometer

Based on these investigations as well as on the experience gained through the first round robin, the GE1 working group

has then established more stringent operating conditions for a new circular test program. A particular emphasis has been

laid on the control of sample preparation and on the verification that the rheometers were operated under the appropriate

torque conditions as well as within the linear domain of viscoelastic behaviour. This new round robin has however been

limited to a single straight-run bitumen (50/70) and the “most difficult” polymer modified binder (PmB2) which had

already been used in the previous studies.

Table 1 : Equipment used

Laboratory "DSR" parallel plate Linear loading (TC-AS)

Although a few laboratories could only A Bohlin Gemini 200 ADS

contribute to a limited extent, the participating B1 Anton Paar MCR 501

laboratories have been essentially the same as B2 Rheometrics ARES

for the first round robin (with one newcomer C Haake RS 600

for the final round robin). Their coded D Anton Paar MCR 500

designation (Lab. A, B, …. ) has thus not been E Haake MARS II

F TA Instr. AR 2000

changed [1]. For several laboratories, the used

G Rheometrics ARES

equipment (see Table 1) has however changed. I Haake RS 150 METRAVIB DMA 450+

J Anton Paar MCR 501

K Anton Paar MCR 501 METRAVIB VA 4000

3. TEST RESULTS OBTAINED WITH A REFERENCE PRODUCT

3.1 Parallel plate rheometers

In first instance, the tests with the reference product have been conducted at 25°C on DSR rheometers using 8mm

plates, with a 1mm gap and a deformation of 1%. A good agreement has been obtained in-between the different

laboratories and the results are also perfectly in line with the stiffness values (reference) indicated by the supplier of the

PDMS product (Figure 1). At frequencies above 10Hz, and even more importantly above 50Hz, these results tend

however to be slightly more scattered. Most of the laboratories have conducted these tests 3 to 5 times, which allows the

calculation of a coefficient of variation (expressed as the ratio, in %, of the standard-deviation over the mean value).

These values, which can be seen as an indicator for repeatability, are gathered in Table 2. One notices some differences

depending on the type of equipment and frequency range.

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

Table 2 : Test results obtained with PDMS reference product - Coefficient of Variation (repeatability)

Laboratory A B1 D E F F I J

Equipment Bohlin 200 MCR 501 MCR 500 Haake Mars II AR 2000 AR 2000 RS 150 MCR 501

Plate diameter (mm) 8 8 8 8 8 25 8 8

Strain (%) 1 1 1 1 1 10 1 1

Frequency range (Hz) 0.1 - 10 0.1 - 100 0.1 - 100 0.1 - 8 0.1 - 10 0.1 - 10 0.1 - 40 0.1 - 100

Number of repetitions 5 4 3 5 5 3 2* 3

Coefficient of Variation (%) on Modulus (|G*|)

0.1 Hz - 10 Hz 1.7 - 4.6 0.2 - 1.6 0.2 - 1.7 ~ 9.5 ~ 10.5 0.2 - 1.4 0-2 ~ 6.8

10 Hz - 50 Hz 0.3 - 5 0.3 - 4 0.5 - 1.5 6.8 - 20

Freq. for which CV > 10 % - ≥ 60 ≥ 80 ≥ 20

50 Hz - 100 Hz - rapid increase 4 - 15 ~ 20

Coefficient of Variation (%) onPhase Angle (d)

0.1 Hz - 10 Hz 0.1 - 5 0.2 - 0.5 0.1 - 2.4 0.1 - 2 0.1 - 1 < 0.1 0 - 0.6 0.1 - 3

10 Hz - 50 Hz 0.4 - 10 0.5 - 4.5 0 - 2.5 rapid increase

Freq. for which CV > 10 % ≥ 50 ≥ 80 ≥ 20

50 Hz - 100 Hz rapid increase 4.5 - 18 no data

* CV = 0.5*(MAX-MIN)/MEAN

One laboratory (Lab. F) repeated the test with a 25mm plate geometry and a strain of 10% and noticed a better

repeatability. This is most likely due to the fact that the 25mm plate geometry is better suited for the relatively low

stiffness of the PDMS product (indeed, the reference values indicated by the supplier are given for 25m plates !). This

observation could be further supported by a few additional tests (although without repetitions) comparing results with

8mm and 25mm plates at different strain levels. Figure 2 shows that only the 25mm geometry allowed to obtain exactly

the same stiffness ratio when changing the equipment (B1/B2) or when changing the applied strain level (1% vs 10%).

"DSR-8mm" : PDMS reference at 25°C "DSR" : PDMS reference at 25°C

1.E+05 100 different test conditions

1.3

90

Modulus Ratio cond.1 / cond.2

1.2

80

1.1

Phase Angle d (°)

70

Modulus |G*| (Pa)

1.E+04

60 1.0

50 0.9 Lab - Plate(mm) -Strain(%)

40 B1-8-1 / B2-8-10

0.8

1.E+03 B1-25-1 / B2-25-1

Lab. A Lab. B1 30

0.7 F-25-1 / F-25-10

Lab. D Lab. E 20

Lab. F Lab. I 0.6 B1-25-1 /B1-8-1

10

Lab. J PDMS Ref. F-8-1 / F-8-10

0.5

1.E+02 0

0.1 1.0 10.0 100.0

0.1 1.0 10.0 100.0

Frequency (Hz) Frequency (Hz)

Figure 1 : tests on PDMS reference with 8mm plates Figure 2 : compared tests on PDMS reference

These results illustrate that, also when using a reference product, care has to be taken to select the adequate test

geometry and strain level. Comparing rheometers over a wide range of stiffness values may thus require to use several

reference products !

When performing the final round robin (see § 5), the tests with the PDMS reference and the 25mm plates have been

repeated by the different laboratories and the agreement proved to be excellent and better than with the 8mm plates

(Figure 3). The coefficient of variation for the mean

"DSR-25mm" : PDMS reference at 25°C results obtained by each laboratory at, for instance, 1Hz,

1.E+05 100 drops from 7% with the 8mm plates to 4% with the

90 25mm plates.

80 We could thus conclude that there was no bias between

Phase Angle d (°)

the different types of DSR equipment used for our

Modulus |G*| (Pa)

Lab. A 70

1.E+04

Lab. B1

Lab. B2

60 investigations.

50 An important remark is however to be made concerning

Lab. F

40

1.E+03

Lab. F-10% temperature regulation. If, as for the PDMS, the stiffness

Lab. J 30

of the reference product is not or only slightly

Lab. K 20

PDMS Ref. temperature dependent, off-sets between two pieces of

10

1.E+02 0

equipment due to poor temperature regulation will not be

0.1 1.0 10.0 100.0 detected on the basis of comparative testing !

Frequency (Hz)

Figure 3 : tests on PDMS reference with 25mm plates

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

3.2 Test performed under annular shear conditions Annular Shear : PDMS reference at 25°C

1.E+05 100

In this case, tests with the PDMS product could only be 90

performed under annular shear (AS) configuration. Since 80

1.E+04

only two laboratories used this type of equipment, 70

Phase Angle d (°)

Modulus |G*| (Pa)

general conclusions cannot be drawn. A fairly good 60

agreement with the DSR results is obtained by Lab. I. For 1.E+03 50

Lab. K, however, we notice a systematic off-set of the PDMS Ref. 40

stiffness modulus (Figure 4). A possible reason could be Lab. I - AS - |G*| 30

1.E+02

the difference in the gap between cylinder and plunger Lab. K - AS - |G*| 20

Lab. I - AS - delta

(1 mm for Lab. I vs. 0.5mm for Lab. K), but this point 10

Lab. K - AS - delta

has not been further investigated. The off-set is not seen 1.E+01 0

for the phase angle, but results are also less stable. 0.1 1

Frequency (Hz)

10 100

Figure 4 : annular shear tests on PDMS reference

4. INVESTIGATION OF SOME OPERATING PARAMETERS

4.1 Impact of waiting time between molding of test sample and beginning of test procedure

These tests have been performed by laboratory E with the 25mm parallel plate geometry, the test samples being cast in

silicon molds. 30 minutes after casting, samples were trimmed, then either immediately tested or allowed to rest at room

temperature for 1, 13, 17, 21 or 24 hours. Comparisons have been done on the basis of a frequency sweep (up and

down) at 40°C. In the case of the 50/70 bitumen, rest

time did not have any impact on the results. In the case of DSR-25mm : PmB2 - d at 40°C

the plastomer modified binder (PmB2), no effect was 58

seen for the modulus but, at low frequencies, differences 56

of more than 6° could be observed for the phase angle

Phase Angle d (°)

54

(Figure 5). It is possible that the short waiting times (0h

and 1h) correspond to a stage where the binder has not 52

yet reached its full equilibrium and where the polymer 50 delay : 0 h

phase has a stronger impact on the elastic component delay : 1 h

48 delay : 13 h

than under stabilized conditions (longer waiting times). delay : 17 h

This phenomenon would however be different from the 46 delay : 21 h

structuring effect due to thermal history which has later 44

delay : 24 h

been observed when performing the final round robin test 0.1 1 10

(§ 5.2). Frequency (Hz)

Figure 5 : DSR tests : impact of sample curing time

4.2 Loading the sample on the rheometer – Impact of bonding temperature

When loading a test sample on the rheometer, a sufficiently high temperature of the parallel plates is necessary to

ensure proper bonding, especially in the case of viscous products such as polymer modified binders. This point has been

investigated by laboratory I with PmB2, based on

DSR - PmB2 : Impact of bonding temperature

frequency sweeps performed at 40°C and 10°C with

62 respectively 20mm (2mm gap) and 8mm (1.5mm gap)

60 geometries. In each case, test samples have been bonded

58 at either 80°C or 30°C. This did not have any significant

impact on the measured stiffness modulus (|G*|) values.

Phase Angle d (°)

56 Bonding at 80 °C - Test at 40°C - 20mm plate

54

Bonding at 30 °C - Test at 40°C - 20mm plate Again, differences appeared however in the case of the

Bonding at 80 °C - Test at 10°C - 8mm plate

52 Bonding at 30 °C - Test at 10°C - 8mm plate

phase angle. Lower phase angles have been measured for

the specimen bonded at 80°C, which could however not

50

be readily explained. It is suspected that both the initial

48

“reheating” of the sample and the time elapsed between

46

bonding and actual testing, which has been longer for the

44 specimen mounted at 80°C, may have affected differently

0 2 4 6 8 10 12

Frequency (Hz) the evolution of the internal structure of the binder.

Figure 6 : DSR tests : impact of sample bonding temperature

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

4.3 Gap setting

Theoretically, during temperature changes, metal can expand or contract, which changes the exact value of the gap

between the parallel plates and, hence, modifies the way it is filled by the test sample with a possible incidence on the

test result. When performing a temperature sweep, eliminating this possibility would require to “zero” the gap at

different temperatures before starting the test procedure. A small investigation on this issue has been made by

Laboratory B with the 25mm plate geometry (B1-MCR501), using a 35/50 straight-run bitumen. Three different

samples were set between the plates after the gap was zeroed at respectively 0°C, 60°C and 120°C. The modulus of

each sample (gap of 2mm) was determined at 60°C following a frequency sweep from 0.1 Hz to 10 Hz. No differences

in results were found, which support the idea that, in the case of temperature sweeps, zeroing of the gap may be done at

a single temperature, which simplifies the test procedure.

On the same line, one may even more wonder about the possible incidence of the actual gap setting (sample thickness

between the plate) on the measured values. This point has also been addressed by Laboratory B (B1-MCR501), again

with a 25mm plate geometry, through tests conducted on

DSR-25mm : |G*| in relation to gap the 35/50 bitumen at 40°C and 60°C, as well as on a PmB

1.E+05

35/50 (0.1 Hz T=40°C) sample (this time of an elastomeric type) at 60°C, the gap

35/50 (0.1 Hz T=60°C) being varied from 0.01mm to 3mm. As it can be seen on

1.E+04 PMB (0.1 Hz T=60°C) Figure 7, the gap setting only started to significantly

Modulus |G*| (Pa)

affect the results below 0.5mm. This study is of course

1.E+03

only partial and results may be different at lower test

temperatures (minimum gap could be different due to the

higher rigidity of the sample) and with a different

1.E+02

geometry (8mm plates). But it may probably be

concluded that, for the usual gap values such the ones

1.E+01 used in the GE1 round robin (2mm for the 8mm plates

0.001 0.01 0.1 1 10 and 1mm for the 25mm plates), a minor deviation from

Gap (mm)

the nominal value should not be of any consequence.

Figure 7 : DSR tests : impact of gap setting between both plates

4.4 Sample trimming

1 : levelled gap (barrel 2 : overfilled gap 3 : underfilled gap

effect)

Figure 8 : schematic representations of extreme gap filling conditions

Gap filling conditions, as shown in Figure 8, are known to influence test results. This point has been once more

confirmed by laboratory B (B2-ARES) with the 35/50 bitumen and the 8mm plate geometry. At first, the sample was set

between the two plates at a gap of 1.0 mm under “overfilled” conditions (configuration 2 in Figure 8) and G* was

measured under a frequency sweep at 40°C. Then, the bitumen was levelled for a new G* measurement (config. 1); the

bitumen being trimmed at gap +50 µm. After that, a gap of 1.1 mm was applied on the same sample (the gap is

underfilled – config. 3) and a measurement of G* was done. Then a gap of 0.9 mm (“overfilled” – config. 2) was

applied, and G* was measured. Finally, the bitumen was again levelled (config. 1), and G* was re-measured.

The “leveled” gaps (barrel effect) gave very similar G* modulus values with a coefficient of variation (defined as

0.5*(MAX-MIN)/MEAN) of about 3%. Overfilling or underfilling the gap by 10% lead to an artificial increase,

respectively decrease, of the G* values by about 12%. Uncontrolled filling of gap may thus lead to an overall error of

more than 20% on the modulus values. This highlights once more that proper trimming of the test sample is a key step

in the operating process.

4.5 Thermal history

Because of its possible impact on the internal structure of the binder, be it due to the presence of crystallized fractions

or of polymers, the thermal history of the sample may impact the measured stiffness and phase angle values [3]. In the

frame of the preliminary studies to the second GE1 round robin test, Laboratory J has performed, on both the 50/70

penetration grade and the PmB2 modified bitumen, a temperature sweep from 70°C down to -30°C (8mm parallel

plates, 2mm gap) and compared the results obtained while observing a stabilization time of either 15 min or 30 min. at

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

each test temperature. In the case of the 50/70 bitumen, no significant differences (compared to the general level of

repeatability observed in the first round robin trials) have been observed. In the case of PmB2, differences became

significant as from 0°C (hence after longer overall time on the rheometer), the stiffness values measured after 30 min. of

stabilization being higher than those measured after only 15 min. Differences appeared even earlier (as from 40°C) for

the phase angle. In certain cases, temperature equilibration time may thus have an incidence and it is not advised to

extent this time above the minimum needed for temperature equilibrium (15 min. are felt to be adequate).

In the frame of a small study limited to PmB2, variations have also been observed by Laboratory A in relation to the

applied temperature sequence. Directly after loading the sample onto the rheometer at 30°C (8mm plate, 1.5mm gap),

frequency sweeps (0.1 Hz to 10 Hz) have been performed at 30°C, then at 10°C, again at 30°C, then at 50°C and finally

a third time at 30°C. Especially at low frequencies, significantly lower stiffness and higher phase angle values where

measured after the cooling down phase, these differences becoming close to nil towards 10 Hz.

4.6 Magnitude of applied strain – limit of the linear domain of behaviour

For the final round robin, all laboratories have been asked to determine, for each test geometry, test temperature and

type of binder, the limits of the linear domain of viscoelasticity. For the sake of reproducibility, it is indeed important to

ensure that the strain applied by each laboratory stays below these limits. Even if, for “conventional” products such as

pure bitumen, experience rapidly tells which strain levels are not to be trespassed, such a verification should not be

neglected in the case of unknown products. The procedure adopted by the working group consisted in “sacrificing” one

test sample per test geometry. Strain sweeps are made at the highest foreseen test frequency (frequency at which the

linear domain should be the shortest) and conducted over the full temperature range to be covered with the geometry,

starting from the lowest. One gets thus a limiting strain at each temperature, from which “safe” strain levels (which may

of course be common for several test temperatures) are then defined. Although there is some risk for premature damage

of the sample, this procedure has been adopted since it is

Strain sweeps at 10°C-25Hz (50/70 bitumen)

easier to proceed from low to high temperatures rather 1.E+08 36.0

than the opposite. It is to be mentioned here that the

35.5

limiting strain (defined as the value above which the Modulus

modulus differs by more than 5% of its initial value) is Phase Angle

Phase Angle d (°)

35.0

Modulus |G*| (Pa)

not always easy to define due to the fluctuations observed 34.5

during the first measurement cycles which may also

34.0

affect the definition of a regression line. An interesting

suggestion has been made by Laboratory D which 33.5

observed that, in many cases, the deviation from a

33.0

constant value is sharper and easier to detect for the

phase angle than for the modulus. This point is illustrated 1.E+07 32.5

0.001 0.01 0.1 1 10

in Figure 9 and should be kept in mind by practitioners. Strain (% )

F

Figure 9 : Definition of linear domain of viscoelasticity

Finally, it is to be further mentioned that adequate strain levels have not only to be defined for the sake of linearity, but

also to ensure that the rheometer is working in an adequate torque range. At each test temperature and frequency, the

strain must be such that the required torque stays within the proper working range. These limits (there is as well an

upper as a lower limit) are specific to each apparatus and test geometry. As for the limits of the linear domain, they

should be checked prior to the actual testing and further verified (by comparing the asked strain level to the strain

actually delivered by the equipment) when analyzing the measurement results.

5. FINAL ROUND ROBIN TEST

For the final Round Robin test program, each laboratory had to follow strict operating conditions. Those included

precise sample re-heating and conditioning instructions, minimum and maximum delay to be observed between the

casting of the sample and its placement onto the rheometer, bonding temperature (60°C for the 50/70 bitumen, 80°C for

PmB2), stabilization time at each temperature (15 minutes for parallel plate and AS samples, 30 minutes for TC

samples). For DSR and annular shear measurements, after installation of the sample, temperature was to be dropped to

the lowest test temperature and temperature sweeps to be conducted from that temperature upwards. Tension-

compression tests were conducted from upper to lowest temperature. All laboratories made a preliminary verification of

the visco-elatic domain and the operational limits to be observed for their equipment. The measurements performed by

each laboratory for the 50/70 bitumen and the PmB2 binder are shown in Table 3 and 4.

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

Table 3 : Overview of Final Round Robin measurements performed on the 50/70 bitumen

"DSR" "TC - AS"

50/70 Lab. A Lab. B1 Lab. D Lab. F Lab. G Lab. J Lab. K Lab. I Lab. K

BG-200 ADS AP-MCR 501 AP-MCR 500 TA-AR2000 ARES AP-MCR 501 AP-MCR 501 DMA 450+ VA 4000

Geometry 8-2 25 - 1 8-2 25 - 1 8-2 25 - 1 8-2 25 - 1 8 - 1.8 25 - 1.8 8-2 25 - 1 8-2 25 - 1 9 - 16 10-8 - 5 8 - 16 10-9 - 5

Sample bonding temp. (°C) 60 60 60 40 60 60 60 T amb T amb

Test temperature

-30

-20

-10

0

10

20

30

40

50

60

70

80

Parallel plate - F in mm, gap in mm Tension - Compression - F in mm, height in mm

Parallel plate - F in mm, gap in mm Annular Shear - Fext - Fint in mm, height in mm

Table 4 : Overview of Final Round Robin measurements performed on the PmB2 binder

"DSR" "TC - AS"

PmB2 Lab. A Lab. B Lab. D-1 Lab. D-2 Lab. D-3 Lab. F Lab. G Lab. J Lab. K Lab. I

BG-200 ADS AP-MCR 501 AP-MCR 500 TA-AR200 ARES AP-MCR 501 AP-MCR 501 DMA 450+

Geometry 8-2 25 - 1 8-2 25 - 1 8-2 25 - 1 8-2 8-2 25 - 1 8-2 25 - 1 8 - 1.8 25 - 1.8 8-2 8-2 25 - 1 9 - 16 10-8 - 5

Sample bonding temp. (°C) 80 80 80 80 40 40 60 80 80 T amb

Test temperature

-30

-20

-10

0

10

20

30

40

50

60

70

80

Parallel plate - F in mm, gap in mm Tension - Compression - F in mm, height in mm

Parallel plate - F in mm, gap in mm Annular Shear - Fext - Fint in mm, height in mm

5.1 Final Round Robin DSR results –50/70 bitumen.

After rejecting outliers (relatively few), reproducibility for DSR data has been evaluated by calculating a coefficient of

variation (in %), defined as the standard deviation (s-value) divided by the mean (m-value). The comparison to the

corresponding values obtained from the first Round Robin [1], is shown in Table 5. Reproducibility is significantly

improved for |G*|, especially at the lower frequencies. The s/m values are now in a range of 10 to 15% with the 8mm

plates and stay lower than 10% with the 25mm plates. Concerning the phase angle, the situation could not be

significantly improved. This may be attributed to the fact that the results obtained in the first Round Robin were already

quite good and that the impact of operating parameters such as waiting time and bonding temperature evidenced in § 4.1

and § 4.2 is probably not as significant in the case of pure bitumen than in the case of a highly modified PmB.

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

Table 5 : Comparison of Final Round Robin with First Round Robin [1] – 50/70 bitumen

Evaluation of reproducibility : values of s/m (%) (s = standard deviation, m = mean)

50/70 Modulus |G*| - 8mm plates Phase Angle d - 8mm plates

Temp. (°C) 0.01 Hz 0.1 Hz 1 Hz 10 Hz 0.01 Hz 0.1 Hz 1 Hz 10 Hz

-10 15.0 11.9 13.1 14.6 3.9 4.5 6.5 7.3

0 6.6 2.1 12.5 3.2 6.0 3.5 3.8 3.9 5.1 5.5

10 11.8 25.2 11.4 19.6 10.7 13.1 12.5 9.3 1.6 1.3 2.3 1.7 1.8 2.7 1.4 2.5

20 16.7 38.1 16.1 32.0 13.8 25.6 11.8 20.4 0.7 1.1 1.3 1.1 1.1 1.8 2.2 2.7

30 12.3 39.0 12.0 34.7 11.2 23.6 10.1 23.1 0.8 0.4 0.8 0.8 1.1 1.5 2.3 0.9

40 12.1 38.5 13.6 24.8 13.7 17.7 12.9 25.2 0.4 1.1 0.4 1.0 1.0 1.8 2.1 3.6

50/70 Modulus |G*| - 25mm plates Phase Angle d - 25mm plates

Temp. (°C) 0.01 Hz 0.1 Hz 1 Hz 10 Hz 0.01 Hz 0.1 Hz 1 Hz 10 Hz

40 9.9 31.4 10.1 26.6 10.9 24.1 7.1 19.4 1.0 0.6 0.6 0.9 0.3 1.4 1.5 2.8

50 8.3 30.8 8.5 14.6 7.8 13.1 7.5 4.8 0.3 0.5 0.2 0.4 0.4 0.8 1.2 1.0

60 5.9 24.2 6.0 12.8 6.1 13.8 6.4 9.4 0.7 0.3 0.2 0.5 0.2 0.5 0.8 1.2

70 5.7 25.8 6.6 10.3 6.5 15.3 6.5 12.3 0.8 0.2 0.9 0.9 0.2 0.6 1.0 2.1

80 16.4 31.1 6.1 9.0 8.7 15.6 10.2 11.5 1.7 0.4 1.1 0.2 0.6 0.7 1.1 2.4

Bold font Values obtained in the final Round Robin

Normal font Values obtained in the first Round Robin [1]

5.2 Final Round Robin DSR results – PmB2 binder.

The results proved to be less positive in the case of the modified binder. As it can be seen in Table 6, reproducibility for

|G*| could only be improved at higher frequencies (1Hz and 10Hz). No improvement could be reached for the phase

angle and results are even worse with the 25mm plates at low frequencies (0.01 Hz and 0.1 Hz). These dispersions are

illustrated in Figure 10 for the 8mm plates (measurements at 10°C) and in Figure 11 for the 25mm plate. The

improvements expected from the investigations reported under § 4 have thus been outbalanced by other factors which

we tried to discover through a closer analysis of data in relation to operating conditions.

Table 6 : Comparison of Final Round Robin with First Round Robin [1] – PmB2 binder

Evaluation of reproducibility : values of s/m (%) (s = standard deviation, m = mean)

PmB2 Modulus |G*| - 8mm plates Phase Angle d - 8mm plates

Temp. (°C) 0.01 Hz 0.1 Hz 1 Hz 10 Hz 0.01 Hz 0.1 Hz 1 Hz 10 Hz

-10 23.0 14.4 7.5 4.5 9.0 10.8 13.9

0 23.6 18.3 13.5 20.6 9.0 20.6 10.4 3.6 4.4 5.2 5.3 4.1

10 30.8 24.9 20.4 21.1 16.5 23.0 17.0 22.5 6.3 6.7 5.9 3.7 5.1 3.0 1.8 4.5

20 28.1 26.3 23.9 25.4 18.0 27.1 13.1 23.4 6.8 10.4 4.1 4.1 4.9 3.1 4.6 3.3

30 26.7 30.8 23.1 24.7 19.4 26.9 14.8 27.2 8.6 8.1 4.6 9.0 3.6 3.3 4.1 2.8

40 31.7 25.3 27.2 30.8 14.4 22.2 17.4 27.3 11.7 15.0 7.8 6.6 5.4 5.3 6.2 3.0

PmB2 Modulus |G*| - 25mm plates Phase Angle d - 25mm plates

Temp. (°C) 0.01 Hz 0.1 Hz 1 Hz 10 Hz 0.01 Hz 0.1 Hz 1 Hz 10 Hz

40 54.6 52.2 32.3 35.0 20.8 30.0 21.2 24.9 35.5 17.2 17.7 8.1 5.7 4.0 3.5 4.4

50 43.8 32.3 21.8 16.2 9.8 18.7 12.2 18.1 36.8 12.6 21.2 6.5 8.6 5.0 2.3 2.0

60 26.5 15.5 13.9 16.7 13.3 24.2 13.3 21.5 22.3 6.8 11.1 9.5 3.9 3.2 1.5 1.9

70 21.9 51.2 23.1 40.5 21.4 38.8 21.0 27.5 1.6 2.8 1.0 2.2 1.3 1.5 1.2 2.1

80 19.4 32.6 17.4 34.7 16.4 0.0 16.2 23.7 2.5 1.1 0.6 1.2 1.0 1.6 1.7 2.3

Bold font Values obtained in the final Round Robin

Normal font Values obtained in the first Round Robin [1]

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

DSR-8mm - PmB2 : |G*| and d at 10°C

1.E+08 70

Lab. A Lab. B

Lab. D-1 Lab. D-2

65

Lab. D-3 Lab. F

Lab. G Lab. J 60

Phase Angle d (°)

Modulus |G*| (Pa)

Lab. K

1.E+07

55

50

45

1.E+06

40

35

1.E+05 30

0.001 0.010 0.100 1.000 10.000 100.000

Frequency (Hz)

Figure 10 : Final Round Robin Test on PmB2 – 8mm plates

When observing the curves obtained for the phase angle at 40°C and 60°C (Figures 11-b and 11-c), one does indeed

distinguish 2 families of curves. For Laboratories A, B and D-1, tests have been performed as prescribed : bonding of

the samples at 80°C, then drop in temperature down to 40°C and performing the temperature sweep upwards. In this

case, one may assume that after an initial partial “melting” of the polymer network due to the high bonding temperature,

re-structuring of this network could not take place, the first testing temperature being still relatively high and being

reached quickly. Hence the relatively high phase angle values. Laboratory K also applied this procedure, however the

first testing temperature was far lower (10°C) and it took thus a much longer time to get there, giving the polymer

network the opportunity to restructure itself. Laboratories D-3 and F did not follow the planned procedure and bonded

their sample at 40°C (i.e. the first test temperature). In this case, there was probably no initial partial “melting” of the

polymer network, which would explain the lower phase angle values, as for Lab. K. The same explanation could

possibly also apply to Laboratory G which bonded its sample at 60°C. It seems further quite logical that at higher test

temperatures, at which the polymer network starts to “melt” again, the differences due to the thermal history of the

sample disappear (Figure 11-d).

Fig. 11-a : DSR-25mm - PmB2 |G*| at 40°C Fig. 11-b : DSR-25mm - PmB2 d at 40°C

1.E+06 80

70

Phase Angle d (°)

Modulus |G*| (Pa)

1.E+05

60

Lab. A

Lab. B 50

1.E+04 Lab. D-1

Lab. D-3 Lab. A Lab. B

40

Lab. G Lab. D-1 Lab. D-3

Lab. K Lab. G Lab. K

1.E+03 30

0.001 0.010 0.100 1.000 10.000 100.000 0.001 0.010 0.100 1.000 10.000 100.000

Frequency (Hz) Frequency (Hz)

Fig. 11-c : DSR-25mm - PmB2 d at 60°C Fig. 11-d : DSR-25mm - PmB2 d at 70°C

90 90

80

Phase Angle d (°)

Phase Angle d (°)

70 80

60

50 Lab. A Lab. B 70 Lab. A Lab. B

Lab. D-1 Lab. D-3 Lab. D-1 Lab. D-3

40 Lab. F Lab. G Lab. F Lab. G

Lab. K Lab. K

30 60

0.001 0.010 0.100 1.000 10.000 100.000 0.001 0.010 0.100 1.000 10.000 100.000

Frequency (Hz) Frequency (Hz)

Figure 11 : Final Round Robin Test on PmB2 – 25mm plates

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

5.3 Complementary DSR tests – PmB2 binder.

To support the above exposed analysis, the GE1 working group decided to conduct a small complementary study with

the 25mm plates at a single (most problematic) temperature of 40°C. Thermal history of the sample has been set such as

to allow the polymer network structure to recover in exactly the same way at all laboratories. More precisely, after the

initial bonding at 80°C, the sample has been cooled down to 10°C at a fixed rate of 2°C/min. and maintained at this

temperature for 15 minutes. It has then been reheated at a rate of 1°C/min. to the test temperature of 40°C and

maintained for 15 min. before starting the frequency sweep. The calculated coefficients of variation, as compared to the

first round robin test, are given in Table 7. As it can be seen, the results are markedly improved. This is further

illustrated in Figure 12-a and 12-b. Stiffness values stay much closer at low frequencies. With the exception of Lab. B

(for which the values obtained at frequencies lower than 1 Hz have been withdrawn from the calculation of the

coefficient of variation), all phase angle values follow the same trend. It is also important to mention that both stiffness

and phase angle are now very close to the values obtained at 40°C with the 8mm plate geometry (Figure 13-a and 13-b).

Table 7 : Comparison of Final Round Robin with First Round Robin [1] –

Complementary DSR tests with the PmB2 binder

Evaluation of reproducibility : values of s/m (%) (s = standard deviation, m = mean)

Measurements at 40°C - 25mm plates

PmB2

0.01 Hz 0.1 Hz 1 Hz 10 Hz

Modulus |G*| 9.6 52.2 15.3 35.0 14.7 30.0 16.1 24.9

Phase Angle d 4.2 17.2 4.3 8.1 2.8 4.0 2.0 4.4

Bold font Values obtained in the final Round Robin

Normal font Values obtained in the first Round Robin [1]

Fig. 12-a : DSR-25mm - PmB2 |G*| at 40°C Fig. 12-b : DSR-25mm - PmB2 d at 40°C

1.E+06 70

60

Phase Angle d (°)

Modulus |G*| (Pa)

1.E+05

50

Lab. A Lab. A

Lab. B Lab. B

Lab. C 40 Lab. C

Lab. D Lab. D

1.E+04

Lab. F

Lab. F

30 Lab. G

Lab. G

Lab. J

Lab. J

Lab. K

Lab. K

1.E+03 20

0.001 0.010 0.100 1.000 10.000 100.000 0.001 0.010 0.100 1.000 10.000 100.000

Frequency (Hz) Frequency (Hz)

Figure 12 : Final Round Robin Test on PmB2 – complementary tests with 25mm plates

Fig. 13-a : DSR-8mm - PmB2 |G*| at 40°C Fig. 13-b : DSR-8mm - PmB2 d at 40°C

1.E+06 70

60

Phase Angle d (°)

Modulus |G*| (Pa)

1.E+05

50 Lab. A

Lab. A

Lab. B

Lab. B

40 Lab. D-2

Lab. D-2

1.E+04 Lab. D-3

Lab. D-3

Lab. F

Lab. F 30

Lab. G

Lab. G

Lab. J

Lab. J

1.E+03 20

0.001 0.010 0.100 1.000 10.000 100.000 0.001 0.010 0.100 1.000 10.000 100.000

Frequency (Hz) Frequency (Hz)

Figure 13 : Final Round Robin Test on PmB2 –8mm plates

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

5.4 Comparison to results obtained under annular shear and tension-compression mode of loading

As it can be inferred from Tables 3 and 4, the number of results obtained under linear mode of loading was far too

limited for any statistical treatment. A comparison to DSR data is however still of interest. Tests under linear mode of

loading were performed at frequencies ranging from 7.8 Hz to 200 Hz (Lab. I) and from 1.6 Hz to 250 Hz (Lab. K),

thus at the higher end and in the continuation of the frequencies used for DSR testing (up to 25 Hz). Figures 14 and 15

show a comparison at 10 Hz. In Tension-Compression, a good agreement is obtained, for both |G*| and d by both

laboratories. Concerning the Annular Shear mode, results are also in line for Laboratory I whereas, for Laboratory K,

we observe a similar off-set as the one already evidenced when using the PDMS reference (see § 3.2 and Figure 4).

Fig. 14-a : DSR vs TC-AS - 50/70 - |G*| at 10 Hz Fig. 14-b : DSR vs TC-AS - PmB2 - |G*| at 10 Hz

1.E+09 1.E+09

1.E+08 1.E+08

Modulus |G*| (Pa)

Modulus |G*| (Pa)

1.E+07 1.E+07

1.E+06 1.E+06

8mm plate - Lab. A-B-D-F-G-J-K

1.E+05 1.E+05

25mm plate - Lab. A-B-D-F-G-J-K 8mm plate - Lab. A-B-D1-D2-D3-F-G-J-K

Labo. I - TC 25mm plate - Lab. A-B-D1-D3-F-G-K

1.E+04 Labo. I - AS 1.E+04

Labo. I - TC

Labo. K - TC

Labo. K - AS Labo. I - AS

1.E+03 1.E+03

-30 -20 -10 0 10 20 30 40 50 60 70 80 -30 -20 -10 0 10 20 30 40 50 60 70 80

Temperature (°C) Temperature (°C)

Figure 14 : Comparison of DSR data to TC-AS data : isochrones of |G*| at 10 Hz

Fig. 15-a : DSR vs TC-AS - 50/70 - d at 10Hz Fig. 15-b : DSR vs TC-AS - PmB2 - d at 10Hz

90 90

80 80

70 70

Phase Angle d (°)

Phase Angle d (°)

60 60

50 50

40 40

8mm plate - Lab. A-B-D-F-G-J-K

30 25mm plate - Lab. A-B-D-F-G-J-K 30 8mm plate - Lab. A-B-D1-D2-D3-F-G-J-K

20 Labo. I - TC 20 25mm plate - Lab. A-B-D1-D3-F-G-K

Labo. I - AS

Labo. I - TC

10 Labo. K - TC 10

Labo. K - AS Labo. I - AS

0 0

-30 -20 -10 0 10 20 30 40 50 60 70 80 -30 -20 -10 0 10 20 30 40 50 60 70 80

Temperature (°C) Temperature (°C)

Figure 15 : Comparison of DSR data to TC-AS data : isochrones of d at 10 Hz

6. CONCLUSION

It is envisaged that rheological properties from DSR measurements will be included in future performance related

binder specifications. Achieving acceptable repeatability and reproducibility for “simple” binders such as straight-run

bitumen is, in that respect, not good enough. Indeed, it is essentially for non-conventional binders, such as polymer

modified binders, that rheological properties are more particularly needed. Unfortunately, it is also for these binders that

acceptable precision is most difficult to achieve. This has once more been experienced by the GE1 working group with

the PmB2 binder.

Rheology testing does however not suffer from any evil spell. Possible causes for discrepancies being well known,

rigorously defined and applied test procedures allow reproducibility to be improved to a great extent. For binders prone

to structural changes in relation to time and temperature, and as it has already been demonstrated by others [3,4],

thermal history of the sample is of paramount importance. For comparisons to be meaningful and precision acceptable,

this history has to be strictly defined and controlled, not only during the sample preparation phase, but also during the

testing procedure itself. Furthermore, if DSR data are to be used as performance indicators, the procedure should be

such that the binder tested in the rheometer is in the same state as the binder that is incorporated in the asphalt.

The very positive outcome of the second GE1 Round Robin test program is that reproducibility data then do become

comparable to those achievable with “simple” plain bitumen. Even for “complex” binders, there is thus a future for

performance specifications with rheological parameters from DSR tests. But there will also be a high price to it, i.e.

strictly controlled equipment, strictly defined and applied test procedures and, above all, well trained operators !

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

REFERENCES

[1] Complex Modulus of Bituminous Binders – Results of the Round Robin Test of the GE1 Working Group

(France), B. Eckmann, D. Chabert, O. Moglia, S. Largeaud, P. Descroix, E. Chailleux, V. Mouillet, H. Soenen,

A. Perez-Lepe, S. Nigen-Chaidron, L. Champion-Lapalu, 4th Eurasphalt & Eurobitume Congress, Session 4,

Paper 402-49, Copenhagen 2008.

[2] Results of the RILEM Round Robin Test on Bituminous Binders Rheology, A. Vanelstraete, D. Sybilsky, and

co-authors from RILEM –TC PEB – TG1 « bituminous binders », 2nd Eurasphalt & Eurobitume Congress,

Proc. 303.uk, Barcelona 2000.

[3] Rheological analysis of bitumens by dynamic shear rheometer : effect of the thermal history on the results, V.

Mouillet, L. Lapallu, J.P. Planche, F. Durrieu, 3rd Eurasphalt & Eurobitume Congress, Session 4, Vienna 2004.

[4] The Influence of Thermal History on Binder Rutting Indicators : H. Soenen, J. De Visscher, A. Vanelstraete, P.

Redelius, IJRMPD, - VOL 6/2, pp.217-238, 2005

5th Eurasphalt & Eurobitume Congress, 13-15th June 2012, Istanbul

Vous aimerez peut-être aussi

- Dtu 36.5-1-2 - 1Document22 pagesDtu 36.5-1-2 - 1salifsy100% (2)

- Dossier NSCRF 1062015Document22 pagesDossier NSCRF 1062015jcPas encore d'évaluation

- ModvlvS Clima M FRDocument28 pagesModvlvS Clima M FRQuentinPas encore d'évaluation

- Relazione Luca Mongelli Conclusiva PDFDocument168 pagesRelazione Luca Mongelli Conclusiva PDFnicolamongelliPas encore d'évaluation

- Compte Rendu Sur Les Echangeurs de ChaleurDocument10 pagesCompte Rendu Sur Les Echangeurs de ChaleurMohammed Ben Ali70% (10)

- RGRA_972_HD_EAPIC_cle05ec19 (1)Document6 pagesRGRA_972_HD_EAPIC_cle05ec19 (1)EmmanuelPas encore d'évaluation

- TemperatureDocument66 pagesTemperatureHassan Houdoud100% (1)

- JNGG 2022 Article Plaque Dynaplaque V5Document9 pagesJNGG 2022 Article Plaque Dynaplaque V5Mahamat HamidouPas encore d'évaluation

- Rapport LPC Element-FinisDocument110 pagesRapport LPC Element-FinisJennifer MillerPas encore d'évaluation

- Etude de Pieux Soumis À Des Poussées Latérales Par La Méthode Du Module de RéactionDocument74 pagesEtude de Pieux Soumis À Des Poussées Latérales Par La Méthode Du Module de RéactionKév In0% (1)

- 1097-5la Teneur en EauDocument10 pages1097-5la Teneur en Eauhachani ibrahimPas encore d'évaluation

- Lab Gta 24Document22 pagesLab Gta 24Hassan HoudoudPas encore d'évaluation

- Calibration of Total Stations Instruments at The ESRFDocument14 pagesCalibration of Total Stations Instruments at The ESRFBudi AndresiPas encore d'évaluation

- XP Cen Iso 17892-5Document34 pagesXP Cen Iso 17892-5ZANZANPas encore d'évaluation

- Traceurs Isotopiques Sources Et ProcessusDocument14 pagesTraceurs Isotopiques Sources Et ProcessusMaman Hassan AbdourazakouPas encore d'évaluation

- BLPC 218 5-14Document10 pagesBLPC 218 5-14Midibahai TRAOREPas encore d'évaluation

- Programme Géotech ComplémentaireDocument5 pagesProgramme Géotech ComplémentaireGhassenPas encore d'évaluation

- A3522 PDFDocument26 pagesA3522 PDFAnis SouissiPas encore d'évaluation

- Bitstream 22495Document7 pagesBitstream 22495hichem tazirPas encore d'évaluation

- Bain Marie EtuvesDocument11 pagesBain Marie EtuvesMed Hédi BANNANIPas encore d'évaluation

- AM3513DOCDocument19 pagesAM3513DOCمحمدلمينابراهيمالموريتانيPas encore d'évaluation

- AQUAREF C1c2 2020 EIL Gaye Juin2021Document144 pagesAQUAREF C1c2 2020 EIL Gaye Juin2021yamina soudaniPas encore d'évaluation

- Analsye Combustible CharbonDocument32 pagesAnalsye Combustible CharbonAdil EL FARDAOUI100% (1)

- Caractéristiques de La Dynamique D'un Pneumotachographe Pour L'étude de La Production de La Parole: Aspects Acoustiques Et AérodynamiqueDocument5 pagesCaractéristiques de La Dynamique D'un Pneumotachographe Pour L'étude de La Production de La Parole: Aspects Acoustiques Et AérodynamiqueRaghda BecheriPas encore d'évaluation

- Procédé de Rotomoulage ThèseDocument191 pagesProcédé de Rotomoulage ThèseJulien GilPas encore d'évaluation

- RaffinageDocument16 pagesRaffinageMatchem BensafiPas encore d'évaluation

- Observations Programme CompletDocument11 pagesObservations Programme CompletGhassenPas encore d'évaluation

- Rapport Record01-0119 1ADocument77 pagesRapport Record01-0119 1ANourhen OmriPas encore d'évaluation

- S7.10.13 Essai de Pénétrabilité Des BitumesDocument3 pagesS7.10.13 Essai de Pénétrabilité Des BitumesTina HarryPas encore d'évaluation

- Bulletin Dessai Tuyaux PebdDocument2 pagesBulletin Dessai Tuyaux PebdAli SqlPas encore d'évaluation

- Calcul Enthalpie - Thèse 2005 SOLLIER ADocument257 pagesCalcul Enthalpie - Thèse 2005 SOLLIER ADahmchaPas encore d'évaluation

- Geo Tech 1983023 P 61Document16 pagesGeo Tech 1983023 P 61Okba RezPas encore d'évaluation

- VAUTROT 2012 ArchivageDocument187 pagesVAUTROT 2012 ArchivageKamal PcPas encore d'évaluation

- Gazeification en Lit Fixe Continu CaracterisationDocument9 pagesGazeification en Lit Fixe Continu CaracterisationAttou YasserPas encore d'évaluation

- PR NF en 13968Document37 pagesPR NF en 13968UTIL DOCPas encore d'évaluation

- Experimental Analysis of Mechanical Seals Operating Under The Thermal ShockDocument11 pagesExperimental Analysis of Mechanical Seals Operating Under The Thermal ShockdanyPas encore d'évaluation

- LHB 1998063Document6 pagesLHB 1998063Amine ChettouhiPas encore d'évaluation

- Kinetics of Carbon Dioxide With AminesDocument21 pagesKinetics of Carbon Dioxide With Aminesjiawen dingPas encore d'évaluation

- BOCKOU mi0093-2004Document8 pagesBOCKOU mi0093-2004bockouPas encore d'évaluation

- Article AbbesDocument8 pagesArticle AbbesAhmed HasbellaouiPas encore d'évaluation

- Atd 1Document7 pagesAtd 1MAROUA LAKEHALPas encore d'évaluation

- Procédés Industriels: Traitement Thermique Des Fibres ChimiquesDocument45 pagesProcédés Industriels: Traitement Thermique Des Fibres ChimiquesChaimae GouramPas encore d'évaluation

- Dimensionnement Chaussée Comparaison - DE - FRDocument19 pagesDimensionnement Chaussée Comparaison - DE - FRAziz BadiPas encore d'évaluation

- Hadjadj Uqac 0862D 10284Document193 pagesHadjadj Uqac 0862D 10284farfarfifi3Pas encore d'évaluation

- p67 84 Olympiade Epreuv Prat 1Document36 pagesp67 84 Olympiade Epreuv Prat 1Taim KhouriPas encore d'évaluation

- Cern Irradiation PDFDocument176 pagesCern Irradiation PDFtotorino38Pas encore d'évaluation

- Effet de L'environnement Sur Les Propretés Mécanique Des Tubes de HDPE 2Document70 pagesEffet de L'environnement Sur Les Propretés Mécanique Des Tubes de HDPE 2ahmoudaPas encore d'évaluation

- Boris GEYNET CIM2017 1Document4 pagesBoris GEYNET CIM2017 1bochraPas encore d'évaluation

- XP Cen Iso 17892-12Document18 pagesXP Cen Iso 17892-12asma chengPas encore d'évaluation

- 408 FFFFF 8 CODocument122 pages408 FFFFF 8 CObrailbox abdelkaderPas encore d'évaluation

- Norme en 14175 DES SorbonnesDocument0 pageNorme en 14175 DES SorbonnesYacine JellouliPas encore d'évaluation

- En 1367 - 1Document20 pagesEn 1367 - 1Redha Sabr100% (1)

- Technique de LaboratoireDocument49 pagesTechnique de LaboratoireJean Luc TchoffoPas encore d'évaluation

- Cei 60811-1-2Document18 pagesCei 60811-1-2Bouzid OussamaPas encore d'évaluation

- Des Essais Haute Pression Dans Les Sables Du Thanetien A LondresDocument6 pagesDes Essais Haute Pression Dans Les Sables Du Thanetien A LondressamimontassarPas encore d'évaluation

- prEN933-11 FRDocument11 pagesprEN933-11 FRtinaPas encore d'évaluation

- Th 2013 Der Gal FatihaDocument163 pagesTh 2013 Der Gal FatihasoumiaPas encore d'évaluation

- 05AEP06Document63 pages05AEP06enimaPas encore d'évaluation

- A3520 PDFDocument35 pagesA3520 PDFAnis SouissiPas encore d'évaluation

- Enquete Normes IBGN Oligochètes Oct2016Document9 pagesEnquete Normes IBGN Oligochètes Oct2016fateh lounisPas encore d'évaluation

- Pile Alpha Method 2827Document4 pagesPile Alpha Method 2827LMBong8881Pas encore d'évaluation

- Rapport Géo SNCFTDocument104 pagesRapport Géo SNCFTOussama KtitiPas encore d'évaluation

- Compilation of RadiationDocument160 pagesCompilation of RadiationFelipe GustavoPas encore d'évaluation

- Energie RenouvelableDocument7 pagesEnergie RenouvelableBilel KrayniPas encore d'évaluation

- Epreuve E41 Bts Elec 2019 SujetDocument21 pagesEpreuve E41 Bts Elec 2019 SujetMoulayMoulyPas encore d'évaluation

- Carrier Prijslijst 2022 2023 Be FR - tcm210 137887Document22 pagesCarrier Prijslijst 2022 2023 Be FR - tcm210 137887najimtecPas encore d'évaluation

- TD Thermodynamique2Document8 pagesTD Thermodynamique2ridhajamel100% (1)

- ThermoDocument17 pagesThermoSimo Simow100% (2)

- Thermodynamique 2nd Cycle Procedes Sujet Juin 2020Document3 pagesThermodynamique 2nd Cycle Procedes Sujet Juin 2020promuslim880Pas encore d'évaluation

- Simulation Equation de Diffusion 2D PFE 2020 Version FinalDocument50 pagesSimulation Equation de Diffusion 2D PFE 2020 Version FinalHamza El-watiqPas encore d'évaluation

- CHAPITRE I - Notions Générales de La ThermodynamiqueDocument12 pagesCHAPITRE I - Notions Générales de La Thermodynamiquespidef50% (2)

- Processus D'extraction D'huile de GrignonsDocument3 pagesProcessus D'extraction D'huile de Grignonsouzeouze123Pas encore d'évaluation

- Kit de Traversée-Écran Universel - VDEFDocument2 pagesKit de Traversée-Écran Universel - VDEFpaulPas encore d'évaluation

- Refroidissement Par Évaporation Rapport DéfinitifDocument60 pagesRefroidissement Par Évaporation Rapport DéfinitifAndreas NGASTEPas encore d'évaluation

- td22 th5-2Document2 pagestd22 th5-2El Haddam AsmaePas encore d'évaluation

- C-R TP N°02 (Influence)Document12 pagesC-R TP N°02 (Influence)B.M.D.E MAGICPas encore d'évaluation

- TP 3 SVTDocument2 pagesTP 3 SVTyasser elouartassiPas encore d'évaluation

- Rayonnement Solaire Équivalent - CylindreDocument8 pagesRayonnement Solaire Équivalent - CylindresemvpmPas encore d'évaluation

- Un Point D'isolationDocument68 pagesUn Point D'isolationAymenPas encore d'évaluation

- 5472 Cap FC Ep1 Dossier Technique 2013Document11 pages5472 Cap FC Ep1 Dossier Technique 2013Ahmadou Yerima AbbaPas encore d'évaluation

- CatalaseDocument7 pagesCatalaseLeila MolnarPas encore d'évaluation

- TQM Chaitre I 2023 2024Document16 pagesTQM Chaitre I 2023 2024luckfi binadsPas encore d'évaluation

- Rapport Energetique BatimentDocument99 pagesRapport Energetique BatimentMohamed KHABBAZPas encore d'évaluation

- Comparer 3 Prix Thermopompes - Maxi Air (Thermopompe Murale)Document4 pagesComparer 3 Prix Thermopompes - Maxi Air (Thermopompe Murale)PrixThermopompesPas encore d'évaluation

- OEnoviaPac-C Confort - 610608A (Web)Document32 pagesOEnoviaPac-C Confort - 610608A (Web)AirteamPas encore d'évaluation

- Energie Thermique Et Transfert Thermique Cours 2Document3 pagesEnergie Thermique Et Transfert Thermique Cours 2Zi KoPas encore d'évaluation

- Transfert de Chaleur Par RayonnementDocument11 pagesTransfert de Chaleur Par RayonnementMohammed Reda GailaPas encore d'évaluation