Académique Documents

Professionnel Documents

Culture Documents

Steel Conection With Concrete Shear Wall

Transféré par

mohansanjayTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

Steel Conection With Concrete Shear Wall

Transféré par

mohansanjayDroits d'auteur :

Formats disponibles

460

A constitutive model for analysis of reinforced

concrete solids

R.G. Selby and F.J. Vecchio

Abstract: This paper describes formulations intended to expand the applicability of the modified compression field theory for

general three-dimensional analysis of reinforced concrete solids. The modified compression field theory, which was

specifically developed from tests on cracked reinforced concrete panels, has primarily concentrated on describing the

stress–strain response of reinforced concrete under compression and tension stress states. Recent work has been directed at

refining finite element programs based on the modified compression field theory for problems in which confinement and

lateral expansion effects are important. Proposed stress–strain relationships are based on an orthotropic nonlinear elastic

model that acknowledges the asymmetric response of concrete under multiaxial stress conditions. Lateral expansion of

concrete subjected to compression is modelled under all stress states. The formulation accounts for complex behaviour such as

concrete strength enhancement due to confinement, concrete strength degradation due to transverse cracking, tension

stiffening, and crack slip. The models assume short-term, monotonic loading conditions. A sample analysis of a reinforced

concrete shear wall is presented to illustrate the improved modelling with the consideration of lateral expansion and

confinement effects.

Key words: reinforced concrete, triaxial stress, confinement, lateral expansion, orthotropic, cracking.

Résumé : Cet articles décrit des formulations proposées pour élargir le domaine d’application de la théorie du domaine de

compression modifiée pour le cas général d’analyse tridimensionnelle d’éléments en béton armé. La théorie du domaine de

compression modifiée, qui a été spécifiquement développée à partir d’essais sur des panneaux fissurés en béton armé, s’est

essentiellement concentrée sur la description de la relation contrainte–déformation du béton armé sous des contraintes de

compression-traction. De récents travaux ont été entrepris pour raffiner des programmes d’éléments finis basés sur la théorie

du domaine de compression modifiée afin de considérer des problèmes dans lesquels le confinement et l’expansion latérale

sont importants. Les relations proposées de contrainte–déformation sont basées sur un modèle orthotropique élastique et

non-linéaire qui reconna”t la réponse asymétrique du béton sous l’effet de contraintes multiaxiales. La formulation tient

compte de comportements complexes tels que l’amélioration de la résistance du béton due au confinement, la dégradation de

la résistance du béton à cause de fissurations transversales, le raidissement en tension et le glissement de fissures. L’analyse

d’un mûr de cisaillement en béton armé est présenté pour illustrer la modélisation améliorée en considérant l’expansion

latérale et les effets de confinement.

Mots clés : béton armé, contrainte triaxiale, confinement, expansion latérale, orthotropique, fissuration.

[Traduit par la Rédaction]

1. Introduction assumed to coincide. Cracked concrete was treated as an or-

thotropic material with its own stress–strain relationships in

In an effort to determine more realistic constitutive relation-

terms of average stress and average strain. Of particular sig-

ships for cracked reinforced concrete, Vecchio and Collins

(1982) tested a series of reinforced concrete panels. From these nificance was that these relationships reflected the reduced

compressive strength of concrete in the presence of large trans-

tests, the modified compression field theory, which included

verse tensile strains, and accounted for the significant tensile

stress–strain relationships for cracked reinforced concrete un-

der plane stress conditions, was derived. In this theory, direc- stresses that exist in the concrete between cracks. Local stress

conditions at cracks were also examined. The modified com-

tions of principal stress and directions of principal strain were

pression field theory was shown to be capable of accurately

predicting the response of reinforced concrete elements sub-

jected to in-plane shear and normal stresses.

Received October 24, 1995. Adeghe (1986) and Stevens (1987) were the first to use the

Revised manuscript accepted December 11, 1996.

constitutive models of the modified compression field theory

R.G. Selby. Morrison Hershfield Ltd., 4 Lansing Square, North in finite element work. Each of these programs used a plane

York, ON M2J 1T1, Canada. stress element and was cast in a tangent stiffness algorithm.

F.J. Vecchio. Department of Civil Engineering, University of Some numerical difficulties were encountered in modelling

Toronto, Toronto, ON M5S 1A4, Canada. the softening branches of the concrete stress–strain curves in

Written discussion of this article is welcomed and will be tension and compression. Also, the tangent stiffness matrix

received by the Editor until October 31, 1997 (address inside computed according to the modified compression field theory is

front cover). unsymmetric. (The asymmetry in the tangent material stiffness

Can. J. Civ. Eng. 24: 460–470 (1997) © 1997 NRC Canada

Selby and Vecchio 461

matrix results because the stress–strain relationships of the is implemented in an orthotropic nonlinear elastic model, con-

modified compression field theory state, for example, that the sistent with the crack model. Simple confined concrete

compressive principal stress depends on the compressive prin- stress–strain relationships are developed from basic experi-

cipal strain and the tensile principal strain, but that the tensile mentally observed behaviour of concrete specimens subjected

principal stress depends only upon the tensile principal strain.) to multiaxial compressive stresses. These constitutive relation-

In an attempt to overcome these problems, both Adeghe and ships represent a first attempt at developing triaxial theory to

Stevens were forced to compromise the formulations of the be used with the modified compression field theory.

modified compression field theory. A sample full-scale finite element analysis of a shear wall

To avoid the problems encountered by these tangent stiff- is also presented. The analysis examines the effects of account-

ness approaches, Vecchio (1989) developed a secant stiffness ing for confinement and lateral expansion in a compression

algorithm for analysis of reinforced concrete subject to condi- field based analysis.

tions of plane stress. By using a secant stiffness based ap-

proach, the asymmetry of the stiffness matrix was avoided

while still completely representing the modified compression 2. Finite element formulation

field theory. The program proved to be numerically robust, The finite element program SPARCS was developed (Vecchio

while predicting the strength, deformation pattern, and failure and Selby 1991) to allow for compression field analysis of

mode with good accuracy for a variety of membrane structures reinforced concrete solids. A relatively simple approach is

(Vecchio 1992, 1990, 1989). taken with respect to the finite elements and the solution tech-

The constitutive relationships of the modified compression niques that are employed. The program is based on an iterative

field theory were first used in a three-dimensional finite ele- total stress and strain formulation in which secant moduli are

ment context by Vecchio and Selby (1991). The plane stress defined and progressively refined according to current local

constitutive relationships were tentatively extrapolated to stress–strain states. The program uses relatively low powered

three dimensions. In accordance with the two-dimensional for- brick, wedge, and truss elements based on linear displacement

mulation of Vecchio, the program (SPARCS) used a secant functions. The geometry of the brick and wedge elements is

stiffness algorithm with a smeared, rotating crack model. As a restricted to enable explicit evaluation of the element stiffness

check on the proposed algorithm, a series of reinforced con- matrices, thus avoiding costly numerical integration schemes.

crete beams subjected to varying conditions of flexure and torsion The constitutive relationships of the modified compression

were modelled. The program was able to provide realistic predic- field theory are best implemented into secant stiffness based

tions of ultimate load, failure mode, load–deformation response, algorithms. In the proposed constitutive models, an orthotropic

and local strain conditions. formulation is used for concrete in all stress states. Cracked

This paper discusses some of the recent research work concrete treated by the smeared crack approach is inherently

(Selby and Vecchio 1993) that have been directed at improving modelled as an orthotropic material. In confined concrete, the

these tentative three-dimensional constitutive relationships. In adoption of an orthotropic model allows for the consideration

particular, models to include the effects of lateral expansion of anisotropic behaviour near ultimate.

and confinement are formulated to be compatible with the ex- The three-dimensional orthotropic material stiffness matrix

isting cracked concrete theory. The confined concrete theory can be written in the principal directions as

Ec1(1 − ν32ν23) Ec1(ν12 + ν13ν32) Ec1(ν13 + ν12ν23) 0 0 0

Ec2(ν21 + ν31ν23) Ec2(1 − ν31ν13) Ec2(ν23 + ν21ν13) 0 0 0

1 Ec3(ν31 + ν21ν32) Ec3(ν32 + ν12ν31) Ec3(ν23 + ν21ν13) 0 0 0

[Dc]′ =

0

[1]

φ 0 0 0 φGc12 0

0 0 0 0 φGc23 0

0 0 0 0 0 φGc31

where Eci is the modulus of elasticity in the i-direction, the Poisson’s ratio νij is the component of strain in the i-direction due to a

stress in the j-direction, and

[2] φ = 1 – ν32ν23 – ν21ν12 – ν31ν13 – ν21ν32ν13 – ν31ν12ν23

The three shear moduli are given by

Ec1Ec2

[3] Gc12 =

Ec1(1 + ν12) + Ec2(1 + ν21)

Ec2Ec3

[4] Gc23 =

Ec2(1 + ν23) + Ec3(1 + ν32)

Ec1Ec3

[5] Gc13 =

Ec1(1 + ν13) + Ec3(1 + ν31)

© 1997 NRC Canada

462 Can. J. Civ. Eng. Vol. 24, 1997

Fig. 1. Symmetry conditions in the orthotropic model. stiffness matrices, and therefore the global stiffness matrix, is

retained.

The three-dimensional finite element program SPARCS in-

cludes provisions to model prestrains arising from strain offset

effects such as prestressing of reinforcement, shrinkage or ex-

pansion of concrete, and thermal expansion of either concrete

or reinforcement. For concrete, a prestrain matrix, {εoc }, is de-

fined relative to the global x, y, z system

T

[9]

εoc = εocx εocy εocz γocxz γocyz γoczx

to account for all nonstress-related straining. A similar matrix

is developed for the reinforcement prestrains. An equivalent

force approach is then used to incorporate the prestrain effects.

From the known prestrains, free nodal displacements {rc}and

{rs}are calculated for the concrete and steel, respectively,

rc = ∫ εoc dV

[10]

rs = ∫ εos dV

[11]

The equivalent nodal loads due to the prestrains, {F*}, are

calculated from

n

To maintain symmetry in the stiffness matrix, the following F∗ = [ kc] rc + ∑ [ ks] rs

[12]

three conditions must be satisfied: i=1

i i

[6] Ec1ν12 = Ec2ν21

where [kc] and [ks]i are the element stiffness matrices evaluated

[7] Ec2ν23 = Ec3ν32 separately for the concrete and each reinforcement component.

These equivalent nodal forces due to the prestrains are then

[8] Ec1ν13 = Ec3ν31 added to the externally applied nodal forces to determine the

total nodal forces. The total nodal load vector is updated in

For cracked concrete, most orthotropic material descriptions each iteration, since the equivalent nodal forces depend on the

(i.e., smeared crack models) have assumed that the Poisson’s component stiffnesses.

effects are negligible (e.g., Hu and Schnobrich 1990; Vecchio This algorithm was modified to include the expansion

1989). All off-diagonal terms in [1] become zero, since the six strains due to Poisson’s effect. The expansion strains in the

Poisson’s ratios are neglected, i.e., νij = 0. This assumption is principal directions are written as

relatively good for many situations, but for cases in which the

T

tensile strains in cracked concrete are relatively small, the lat- [13]

εocp = εo1 εo2 εo3

eral expansion of concrete arising from Poisson’s effects can

represent a significant portion of the total strains (Vecchio where

1992). Too much strength degradation, due to transverse

fc2 fc3

cracking, would be predicted in this situation. Also, in triaxial [14] εo1 = −ν12 − ν13

compressive stress conditions the lateral expansion effects Ec2 Ec3

cannot be neglected.

fc2 fc3

The assumption of symmetry in the secant orthotropic [15] εo2 = −ν21 − ν23

model appears to contradict the observed behaviour of con- Ec1 Ec3

crete. The constitutive response of concrete in compression is

characterized by a progressively softening stress–strain curve fc1 fc2

[16] εo3 = −ν31 − ν32

(Fig. 1). Also, concrete exhibits a progressively higher propor- Ec1 Ec2

tion of lateral expansion as compression is increased. Consid-

ering the 2/3-plane of a specimen of triaxially compressed The expansion strains are then transformed to the global x, y, z

concrete for the case when fc3 < fc2, it will generally be the case axes according to

that Ec3 < Ec2 and ν23 > ν32. (Note that tensile values are taken [17]

εoc = [T]εocp

positive.) Thus, in general, eq. [7] cannot be satisfied and an

elastic orthotropic formulation for concrete in accordance with where [T] is the transformation that defines the orientation of

the symmetry conditions cannot accurately represent behav- the principal axes. Equivalent nodal loads are then calculated

iour in which expansion effects are significant. In the proposed as outlined above. This formulation includes all straining aris-

model, the symmetry conditions are not enforced, but an ap- ing from expansion in the global load vector. All of the expan-

proach is used in which the asymmetry is handled through the sion strains are modelled through the prestrain concept so the

material prestrain concept. Thus, the symmetry of the material material stiffness matrix then includes diagonal terms only.

© 1997 NRC Canada

Selby and Vecchio 463

Fig. 2. Expansion prestrains concept: (a) traditional approach, v12 ≠ Ec1Ec3

0 and (b) prestrain approach, v12 = v21 = 0. [24] Gc13 =

Ec1 + Ec3

The principal strains used in eqs. [19]–[21] are strains due to

stress, not total strains. That is, any nonstress-related strains

(due to prestressing, thermal expansion, etc.) and the expan-

sion strains are first subtracted from the total strains before

calculating the principal values. The prestrain approach is

valid for both uncracked and cracked concrete. An iterative

procedure is required for finite element analysis based on this

approach.

The concept can be further explained with the example

shown in Fig. 2. Consider the linear elastic biaxial element

subjected to the uniaxial stress fc2. In the traditional approach,

eq. [1] would be used to determine the strains corresponding

to this stress state. With the prestrain concept, no lateral ex-

pansion is included in the material stiffness matrix (see

eq. [18]). The deformation response comprises an axial strain

under the applied stress (with no corresponding lateral strain)

and a lateral strain produced from the fictitious lateral forces

(with no corresponding axial strain). The magnitude of the

lateral forces is chosen to produce the lateral strain determined

from eq. [14].

3. Material modeling

To describe the response of reinforced concrete, models are

required for strength degradation due to cracking, strength en-

hancement due to confinement, pre- and post-peak stress–strain

response in tension and compression, and concrete lateral ex-

pansion. These factors must be considered when determining

the six material constants (E1, E2, E3, ν12, ν21, ν13) required for

the orthotropic formulation described above.

The constitutive equations for multiaxial stress states are

Ec131 0 0 0 0 0 based on modifications to the concrete uniaxial stress–strain

0 E 0 0 0

curve. The following curve, based on modifications to the

c231 0 work of Thorenfeldt et al. (1987) and Popovics (1973), was

0 0 Ec331 0 0 0 suggested for high strength concrete by Collins and Porasz

[18] [ Dc] ′ =

0 0 0 Gc12 0 0 (1989):

0 0 0 0 Gc23 0 ε3 n

0 0 0 0 0 Gc13 [25] fc3 = − fp

εp n − 1 + (ε3 ⁄ εp)nk

where Ec1, Ec2, and Ec3 are the secant moduli given by where n is given by

fc1 fp

[19] Ec1 = [26] n = 0.80 +

ε1 17

fc2 and k equals 1 for the ascending branch and

[20] Ec2 = fp

ε2 [27] k = 0.67 +

62

fc3

[21] Ec3 = for the descending branch (where fc′ is in MPa). Note that fp

ε3 (positive quantity) and εp (negative quantity) are the peak

stress and the strain at peak stress, respectively.

and the shear moduli are given by

For this curve, the strain at peak stress under uniaxial com-

Ec1Ec2 pression is estimated from

[22] Gc12 =

Ec1 + Ec2 n fc′

[28] εo =

Ec2Ec3 n − 1 Ec

[23] Gc23 = where fc′ is the uniaxial cylinder strength (positive quantity). The

Ec2 + Ec3

effect of the cylinder strength on the shape of this curve is

© 1997 NRC Canada

464 Can. J. Civ. Eng. Vol. 24, 1997

Fig. 3. Concrete constitutive model: (a) effect of fc′ on the shape of the base curve; (b) peak stress and corresponding peak strain in confined

concrete; (c) compressive stress–strain model for confined concrete; (d) increase in Poisson’s ratio near ultimate; (e) strength reduction in

cracked concrete; and (f) tension stiffening.

J2 √J2

fc1 I1

shown in Fig. 3a. The uniaxial stress–strain response of high [29] 2.0108 + 0.9714 + 9.1412 + 0.2312

strength concrete is more linear in the ascending branch, and fc′ 2 fc′ fc′ fc′

the descending branch drops off more sharply as the con- −1=0

crete strength increases. is used to find the stress required in the major compressive

Lateral confining stresses increase the strength and the direction to cause failure, fc3f, in the presence of the stresses

strain at peak stress of concrete cylinders. The strength en- fc1 and fc2. The stress fc3f (a negative quantity) is used as the

hancement is modelled by modifying the peak stress of the peak stress of the base curve and a peak stress factor, Kσ, is

base curve. The failure surface of Hsieh et al. (1979) defined as

© 1997 NRC Canada

Selby and Vecchio 465

fc3f ν21 = ν31

[30] Kσ = −

fc′ [38] ν12 = ν32

ν13 = ν23

While experimental evidence suggests the same factor can be

applied to find the peak stress and the corresponding peak strain For uncracked concrete in tension, the initial Poisson’s ratio is

in cracked concrete, different factors must be applied to fc′ and εo used. Upon cracking in the tensile principal direction, only the

for confined concrete. The peak strain increases much more expansion normal to this direction is set to zero (i.e., ν21 =

rapidly than the peak stress as confining pressure is increased. ν31 = 0, but all other Poisson’s ratios are nonzero). If the interme-

To relate the peak stress factor and the strain at peak stress diate principal direction also cracks, ν12 and ν32 are equated to

factor, Kε, a two-part expression is implemented (Fig. 3b). For zero, too. All Poisson’s ratios are zero if three orthogonal tensile

low peak stress ratios (Kσ < 3), a fit to the data of Kupfer et al. failures occur.

(1969) is used: In cracked concrete, large tensile strains perpendicular to

the principal compressive direction reduce the concrete com-

[31] Kε = 0.2036K4σ – 2.819K3σ + 13.313K2σ – 24.42Kσ pressive strength. Thus, the compressive stress fc3 is made a

+ 13.718 √Kσ + 1 function of the tensile principal strain, ε1, in addition to the com-

pressive principal strain, ε3. The strength reduction factor β

For higher peak stress ratios the expression of Richart et al. (Fig. 3e) for cracked concrete is given by

(1928) is adopted: 1

[39] β =

[32] Kε = 5Kσ – 4 1 + KsKf

The coordinates of the apex of the base curve become where

0.80

[33] fp = Kσ fc′ −ε1

[40] Ks = 0.35 − 0.280

ε

3

fc3 fc3

[34] εp = εoKσ1 − + Kε [41] Kf = 0.1825√

fc′

fc3f f

c3f

and fc′ is expressed in MPa. The Ks factor accounts for the

The ratio fc3/fc3f is a measure of the degree of nonlinearity. When effect of the transverse straining and Kf represents the influence

this value is low, the strain at peak stress is close to Kσεo. Nearer the of the concrete cylinder strength. High strength concrete is

ultimate strength, the strain at peak stress becomes closer to Kεεo. thought to exhibit a more pronounced compression softening ef-

The modified stress–strain curve is then used to determine all three fect due to the smoother fracture planes.

concrete principal stresses from the corresponding principal strains. The peak stress and strain of the base curve are modified to

Increased ductility is evident when concrete is confined. To account for this strength degradation effect

simulate the descending branch (Fig. 3c) of the stress–strain curve

of confined concrete, a modification was made to the modified [42] fp = βfc′

Kent–Park model (Scott et al. 1982). The descending branch is [43] εp = βεo

[35] fc3 = –fp[1 + Zm(εc3 – εp)] ≤ –0.2fp A linear tensile stress–strain relationship is used until the con-

crete tensile principal stress, fc1, reaches the concrete tensile

where strength, ft′, which is estimated from

[36] Zm =

0.5 [44] ft′ = 0.33 fc′

√ (MPa)

0.9

3 + 0.29fc′ εo −I1 + fci Owing to the influence of bond, tensile stresses can develop in

+ + εp the concrete between cracks. Adding a descending branch in

145fc′ − 1000 −0.002 170

the post-cracked region accounts for this tension stiffening ef-

Note that I1 is the first stress invariant, fci is the current stress fect. The response of reinforced concrete in tension (Fig. 3f) is

in the principal direction under consideration, and both εo and given by

εp are negative quantities. This equation assumes that fc′ is Ecε1, 0 < ε1 < εcr

expressed in megapascals (MPa).

Lateral expansion increases rapidly near the peak stress [45] fc1 = ft′

, ε1 > εcr

(Fig. 3d). This behaviour is modelled by a fit to the uniaxial 1 + √

200ε

Poisson’s ratio data of Kupfer et al. (1969): 1

To determine the stress in the intermediate principal direction,

Kσεo eqs. [39] through [43] are used with the appropriate base curve

νo , 0 > εj >

2 if ε2 is compressive, and eq. [44] is used if it is tensile.

[37] νij = The presence of average tensile stresses in the concrete im-

2ε j 2 Kσεo

νo 1 + 1.5 −1 ≤ 0.5, >εj plies local stress increases in the reinforcement at crack loca-

Kσεo 2 tions. Thus, local conditions must be checked to ensure that

the concrete tensile stress calculated from eq. [53] can be

where νo is the initial Poisson’s ratio. This relationship implies transmitted across the crack. The average tensile stress in the

that only three Poisson’s ratios are independent, since concrete must not be greater than the sum of the reserve of

© 1997 NRC Canada

466 Can. J. Civ. Eng. Vol. 24, 1997

Fig. 4. Reinforcement stress–strain relationship. vmax

[49] f ∗c1 =

ci

f

vci c1

Reinforcement stresses are related to strains using an elastic-

plastic formulation that includes strain hardening behaviour.

The constitutive relationship, shown in Fig. 4, is expressed as

Esεsi, 0 < εsi ≤ εy

[50] fsi = fy, εy < εsi ≤ εsh

fy + Esh(εsi − εsh) ≤ fu, εsi > εsh

where Es is the modulus of elasticity, Esh is the modulus of

strain hardening, εsh is the strain at the onset of strain harden-

ing, fy is the yield strength, and fu is the ultimate strength of the

reinforcement. Perfect bond is assumed between the concrete

and steel.

The algorithm used to solve for the stresses and strains in a

reinforced concrete solid under externally applied loads in-

strength of each reinforcement direction taken in the perpen- volves the following steps. An analysis begins by assuming

dicular direction to a crack. If this condition is violated, then linear elastic isotropic material properties. Element stiffness

fc1 must be reduced accordingly. This is expressed algebrai- matrices are calculated and the global stiffness assembled. The

cally as load vector, which includes prestrain and expansion effects, is

then formed. Nodal displacements are determined, from which

n one strain tensor is calculated for each element. Principal

[46] fc1 ≤ ∑ cos2 θci ρi(fyi − fsi) strains and corresponding directions are found. Evaluation of

i=1 the concrete and steel stresses using the constitutive models

permits determination of secant moduli and in turn new mate-

where fyi is the yield stress of the reinforcement, fsi is the aver- rial stiffness matrices. Average secant moduli are calculated

age tensile stress in the reinforcement, and θci is the angle and if they have converged to the specified limit, then the load

between the reinforcement and the normal to the crack surface. stage is complete. Convergence is measured by the root mean

This check is made for the principal tensile direction and also square, taken over the three principal directions for all ele-

the intermediate principal direction, if it is tensile. ments, of the ratio of the newly calculated secant stiffness

Tensile stresses may also be limited if the required shear factor to the previous secant stiffness factor. Typically, the

stresses cannot be supported on the crack surfaces. The local limit for this value is taken as 1.0001. If the load stage is not

increases in the reinforcement stresses may require shear complete, the newly calculated material stiffness values are

stresses on the crack surfaces for equilibrium. As the crack used to perform another linear elastic analysis. Normally, sat-

width increases, the ability of the concrete to transmit shear by isfactory convergence is achieved within 10–25 iterations. A

aggregate interlock decreases. This may inhibit the local stress flowchart of this procedure is shown in Fig. 5.

increases in the reinforcement and in turn limit the average

concrete tensile stress. Crack slip is said to occur if the required

shear stresses cannot be supported at higher crack widths. The 4. Sample analysis

crack width, w, is estimated from

Lefas et al. (1990) tested several walls under conditions of

[47] w = ε1 s constant axial load and monotonically increasing lateral load.

An analysis of one of these walls provides an opportunity to

where s is the crack spacing which must be estimated before examine the effects of accounting for confinement and lateral

an analysis is performed. This can be determined from the expansion in a compression field based analysis. Shear wall

crack control characteristics of the reinforcement, or estimated SW16 (Fig. 6) had a height-to-width ratio of 1.0, a rectangular

from the reinforcement spacing. Vecchio and Collins (1986) cross section, and heavily reinforced, thickened regions at the

suggested that in the absence of compressive stresses on the top and bottom of the wall to facilitate load transfer. The wall

crack, the limiting shear stress (in MPa) on the crack can be was reinforced vertically with two layers of 8 mm diameter

estimated from bars spaced at 60 mm and horizontally with two layers of

6.25 mm diameter bars spaced at 80 mm. Closed ties were

0.18√

fc′ included near the edges of the wall, creating 140 mm wide

[48] ci ≤

vmax concealed columns.

24w

0.3 + The wall showed a ductile response and was able to resist

a + 16

a higher than expected load. This was attributed to the confine-

where a is the aggregate size. This equation requires units of ment of the concrete in the concealed column at the base of

MPa and mm. The calculated shear stress on the crack surface, the wall. Triaxial compressive stress conditions were reported

vci, in the tensile principal direction is compared against vmax

ci . for this region.

If the limiting shear stress is exceeded, then the average con- The concrete properties input to the program were a cylin-

crete tensile stress, fc1, is reduced to f ∗c1 according to der strength of 44.0 MPa, an initial secant modulus of 33 150

© 1997 NRC Canada

Selby and Vecchio 467

Fig. 5. SPARCS solution algorithm.

© 1997 NRC Canada

468 Can. J. Civ. Eng. Vol. 24, 1997

Fig. 6. Details of shear wall SW16. Fig 7. Finite element model of SW16: (a) SPARCS finite element

mesh and (b) reinforced concrete element type zones.

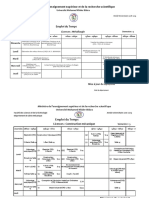

MPa, and an initial Poisson’s ratio of 0.15. The reinforcement

had yield strengths of 470, 520, and 420 MPa for the 8, 6.25,

and 4 mm bars, respectively. The modulus of elasticity of the

reinforcement was 210 000 MPa and strain hardening was as-

sumed to begin at a strain of 2.5 × 10–3, with a strain hardening

modulus of 10 000 MPa.

A mesh of 310 brick elements was used to model the

spreader beams and wall (Fig. 7a). One element was used pressive stress on the compression side of the wall was equal

across the width of a concealed column. Loads were applied to 1.52fc′. At this location, triaxial compressive stress condi-

to the top spreader beam as equivalent nodal loads. The nodes tions resulted because of the passive confinement provided by

along the lower edge of the base were fixed. A smeared steel the hoop steel and the thickened region at the base of the wall.

model was used to account for the presence of the reinforce- The analytical principal compressive stresses in the concrete

ment. Two material zones were defined for the wall and one were fc1 = –1.39 MPa, fc2 = –5.10 MPa, and fc3 = –67.0 MPa.

region each for the spreader beams (Fig. 7b). The reinforcement in the out-of-plane direction was approach-

The vertical load of 460 kN was applied to the top spreader ing yield. The principal compressive strain of –5.80 × 10–3 was

beam and the horizontal load was increased monotonically well into the post-peak regime.

until failure. The ultimate horizontal load of 350 kN obtained An additional analysis was run without consideration of

from the SPARCS analysis compared well with the experi- expansion and strength increase effects. That is, fp was held

mental value of 355 kN. The analytical response involved constant at fc′ and the poisson’s ratios were held constant at

flexural-shear cracking, followed by yielding of the vertical 0.15. The maximum horizontal applied load was reduced to

reinforcement on the tension side, and ultimately crushing of 285 kN (see Fig. 8a). There was a substantial reduction in the

the concrete near the base on the compression side. This was strength and in the ductility near ultimate, but little influence

in agreement with the experimentally observed response. The at low to intermediate load levels. This analysis failed by

load–deformation response was also well represented. The de- crushing of the concrete at the base on the compression side at

flection at the centreline of the top of the wall is plotted against a stress equal to the cylinder strength. Therefore, the confine-

the applied horizontal load in Fig. 8a. The shape of the ment model proved crucial in providing a realistic response for

load–deformation curve matches the measured response, but this wall.

the deflections are somewhat underestimated near ultimate. The SPARCS program has also been able to successfully

Of particular interest is the calculated stress condition near capture the response of a variety of reinforced concrete ele-

the base on the compression side of the wall. The distribution ments, including shear panels, beam elements, and shell elements

of compressive stresses across the base of the wall at the ulti- (Selby and Vecchio 1993; Vecchio and Selby 1991). The pro-

mate load is shown in Fig. 8b. The analytical principal com- gram has also been used to conduct local nonlinear analyses

© 1997 NRC Canada

Selby and Vecchio 469

Fig. 8. Finite element analysis results for SW16: (a) theory accounted for anisotropic behaviour, but did not require

load–deformation response of SW16 and (b) predicted stress enforcement of the unrealistic symmetry conditions. The

distributions along base of wall at ultimate. prestrain approach handled the asymmetry of the material stiff-

ness matrices in a numerically stable manner, with only a mod-

est increase in storage and solution time requirements.

The formulation presented herein is simple and flexible.

Any set of realistic constitutive relationships can easily be in-

corporated into the program. Further work needs to be directed

at improving the preliminary confined concrete stress–strain

models. Also, there is currently a lack of adequate experimen-

tal data from which to calibrate three-dimensional constitutive

relationships for cracked reinforced concrete. The influence of

the intermediate principal strain on the compression softening

and tension stiffening effects could be quantified once suitable

data are obtained.

The analysis of a shear wall demonstrated the significance

of the confinement model in providing a good estimate of

strength. The concealed column at the edge of the wall was

subjected to triaxial stress conditions. Ignoring confinement

effects resulted in a significant decrease in wall capacity and

ductility.

References

Adeghe, L.N. 1986. A finite element model for studying reinforced

concrete detailing problems. Ph.D. thesis, Department of Civil

Engineering, University of Toronto, Toronto, Ont.

Collins, M.P., and Porasz, A. 1989. Shear design for high-strength

concrete. Comité Euro-International du Béton, Bulletin d’Infor-

mation No. 193, pp. 77–83.

Collins, M.P., Vecchio, F.J., Selby, R.G., and Gupta, P.R. 1997. In-

vestigating the failure of an offshore structure. Concrete Interna-

tional, 19(8).

Hsieh, S.S., Ting, E.C., and Chen, W.F. 1979. An elastic-fracture

model for concrete. Proceedings of the 3rd Engineering Mechan-

ics Division Special Conference, American Society of Civil Engi-

neers, Austin, Tex., pp. 437–440.

Hu, H.T., and Schnobrich, W.C. 1990. Nonlinear analysis of cracked

reinforced concrete. American Concrete Institute Structural Jour-

nal, 87(2): 199–207.

Kupfer, H., Hilsdorf, K.H., and Rüsch, H. 1969. Behaviour of con-

crete under biaxial stress. Journal of the American Concrete Insti-

of concrete offshore platforms to investigate reasons for struc- tute, 66(8): 656–666.

tural failure (Collins et al. 1997), and to confirm the design of Lefas, I.D., Kotsovos, M.D., and Ambraseys, N.N. 1990. Behaviour

of reinforced concrete structural walls: strength, deformation char-

critical components (Selby et al. 1996). Work is progressing acteristics and failure mechanism. American Concrete Institute

with regards to application to confined columns and to cyclic Structural Journal, 87(1): 23–31.

and non-proportional loading. Popovics, S. 1973. A numerical approach to the complete stress–strain

curve of concrete. Cement and Concrete Research, 3(5): 553–599.

5. Conclusion Richart, F.E., Brandzaeg, A., and Brown, R.L. 1928. A study of the

failure of concrete under combined compressive stresses. Univer-

A constitutive model was presented for predicting the response sity of Illinois Engineering Experimental Station, Urbana, Ill.,

of reinforced concrete solids subject to short-term monotonic Bulletin No. 185.

loading. The model was built into a finite element program, Scott, B.D., Park, R., and Priestley, M.J.N. 1982. Stress–strain behaviour

thereby permitting three-dimensional nonlinear analyses of of concrete confined by overlapping hoops at low and high strain rates.

complex reinforced concrete structures. Journal of the American Concrete Institute, 79(1): 13–27.

A confined concrete model was developed to be compatible Selby, R.G., and Vecchio, F.J. 1993. Three dimensional constitutive

with the secant stiffness based modified compression field the- relations for reinforced concrete. Department of Civil Engineer-

ing, University of Toronto, Toronto, Ont., Publication No. 93-02.

ory, cracked concrete formulation. The simple constitutive Selby, R.G., Vecchio, F.J., and Collins, M.P. 1996. Analysis of reinforced

equations proposed for confined concrete were capable of pre- concrete sections subjected to shear and high axial compression.

dicting concrete strength enhancement, dilatancy and post- American Concrete Institute Structural Journal, 93(3): 306–315.

peak compressive response under triaxial compressive stresses. Stevens, N.J. 1987. Analytical modelling of reinforced concrete sub-

The orthotropic nonlinear elastic secant algorithm was a jected to monotonic and reversed loadings. Ph.D. thesis, Depart-

successful framework for the confined concrete model. The ment of Civil Engineering, University of Toronto, Toronto, Ont.

© 1997 NRC Canada

470 Can. J. Civ. Eng. Vol. 24, 1997

Thorenfeldt, E., Tomaszewicz, A., and Jensen, J.J. 1987. Mechanical Gc12 secant shear modulus of concrete relative to 1- and 2-

properties of high strength concrete and application in design. axis

Proceedings of the Symposium on Utilization of High Strength Gc23 secant shear modulus of concrete relative to 2- and 3-

Concrete, Tapir, Trondheim, Norway, pp. 149-159. axis

Vecchio, F.J. 1989. Nonlinear finite element analysis of reinforced

concrete membranes. American Concrete Institute Structural Jour-

Gc13 secant shear modulus of concrete relative to 1- and 3-

nal, 86(1): 26–35. axis

Vecchio, F.J. 1992. Finite element modelling of concrete expansion I1 first invariant of stress tensor

and confinement. ASCE Journal of Structural Engineering, J2 second invariant of deviatoric stress tensor

118(9): 2390–2406. Kε strain at peak stress factor (positive quantity)

Vecchio, F.J., and Collins, M.P. 1982. The response of reinforced Kσ peak stress factor (positive quantity)

concrete to in-plane shear and normal stresses. Department of [K] structure stiffness matrix

Civil Engineering, University of Toronto, Toronto, Ont., Publica- [k] element stiffness matrix

tion No. 82-03. [kc] element stiffness matrix evaluated for concrete compo-

Vecchio, F.J., and Collins, M.P. 1986. The modified compression

nent

field theory for reinforced concrete elements subjected to shear.

Journal of the American Concrete Institute, 83(2): 219–231. [ks]i element stiffness evaluated for i-direction reinforce-

Vecchio, F.J., and Selby, R.G. 1991. Toward compression field analy- ment

sis of reinforced concrete solids. ASCE Journal of Structural En- {r} structure nodal displacement matrix

gineering, 117(6): 1740–1758. {rc} free nodal displacements due to concrete prestrains

{rs} free nodal displacements due to steel prestrains

List of symbols s crack spacing

[T] transformation matrix

a aggregate size vci maximum allowable shear stress on crack surface

[B] element strain displacement matrix vmax

ci shear stress on crack surface

[D] composite material stiffness matrix in global axes w crack width

[Dc ]concrete material stiffness matrix in global axes Zm slope factor for post-peak compressive curve

[Dc]′concrete material stiffness matrix in principal directions β strength reduction factor

[Ds]imaterial stiffness in global axes of reinforcement com- εcr strain in concrete at cracking

ponent i εo1 concrete expansion strain in 1-direction

Ec modulus of elasticity of concrete (initial tangent modu- εo2 concrete expansion strain in 2-direction

lus) εo3 concrete expansion strain in 3-direction

Ec1 concrete secant modulus in tensile principal strain di- εo strain in concrete cylinder at peak stress fc′ (negative

rection quantity)

Ec2 concrete secant modulus in intermediate principal strain εp strain at peak stress (negative quantity)

direction εos smeared reinforcement prestrains relative to global axes

Ec3 concrete secant modulus in compressive principal strain εsh strain at onset of strain hardening of reinforcement

direction εsi strain in i-direction reinforcement

Es Young’s modulus of reinforcement εy yield strain of reinforcement

Esh modulus of strain hardening of reinforcement ε1 tensile principal strain

fc′ compressive strength of concrete cylinder (positive εcr

1 tensile principal strain at a crack

quantity) ε2 intermediate principal strain

fc1 tensile principal stress in concrete ε3 compressive principal strain

fc2 intermediate principal stress in concrete {ε} element strain matrix (tension positive)

fc3 compressive principal stress in concrete {εoc } concrete prestrains relative to global axes

fc3f required fc3 to cause failure in presence of fc1 and fc2 {εocp} expansion strains in principal directions

fp peak stress (positive quantity) {εos } smeared reinforcement prestrains relative to global axes

fsi average stress in i-direction reinforcement ρi smeared steel reinforcement ratio in i-direction

fui ultimate stress of i-direction reinforcement νij component of strain in i-direction due to a stress in the

fyi yield stress of i-direction reinforcement j-direction

{F} structure nodal force matrix νo initial Poisson’s ratio

{F*} equivalent nodal loads due to prestrains θci angle between i-direction steel and normal to crack surface

{f} element stress matrix (tension positive)

© 1997 NRC Canada

Vous aimerez peut-être aussi

- Polycopié RDM - Bon CoursDocument91 pagesPolycopié RDM - Bon Coursjustino83% (6)

- Résistance Des Matériaux - Tome 2, TimoshenkoDocument242 pagesRésistance Des Matériaux - Tome 2, TimoshenkoYann FrancoisPas encore d'évaluation

- Dynamique: Les Grands Articles d'UniversalisD'EverandDynamique: Les Grands Articles d'UniversalisPas encore d'évaluation

- 380 e Impression 3d Fabrication Additive en Beton PDFDocument49 pages380 e Impression 3d Fabrication Additive en Beton PDFDumboFièvrePas encore d'évaluation

- Introduction À La Résistance Des MatériauxDocument178 pagesIntroduction À La Résistance Des Matériauxpour_papa100% (1)

- Relativité générale: Les Grands Articles d'UniversalisD'EverandRelativité générale: Les Grands Articles d'UniversalisPas encore d'évaluation

- Support de Cours Sciences Des MateriauxDocument131 pagesSupport de Cours Sciences Des MateriauxChouaib Aribi100% (1)

- Résistance Des Matériaux en Conception MécaniqueDocument432 pagesRésistance Des Matériaux en Conception Mécaniquenafaa_ali137550% (6)

- Renforcement CarboneDocument40 pagesRenforcement Carbonehne100% (1)

- TP CorrigeDocument12 pagesTP CorrigeHadjer Pina92% (12)

- Chec RDM 2011Document9 pagesChec RDM 2011ATOPas encore d'évaluation

- Solutions TD PDFDocument24 pagesSolutions TD PDFKIAS Djahid100% (1)

- Exemple de Calcul D'une Structure Mixte en BADocument27 pagesExemple de Calcul D'une Structure Mixte en BAMouhsineAtb50% (2)

- Hydraulique Du BatimentDocument52 pagesHydraulique Du BatimentMohamed Mehdi100% (1)

- Performance-Based Approach in Seismic Design of Embedded Retaining WallsDocument4 pagesPerformance-Based Approach in Seismic Design of Embedded Retaining WallsBajocarPas encore d'évaluation

- Paper 05 Modelling of A 3D Exca in FE AnalysisDocument17 pagesPaper 05 Modelling of A 3D Exca in FE AnalysisTran Viet ThaiPas encore d'évaluation

- The Influence of Bond Stress Distribution On Ground Anchor Fixed Length Design. Field Trial Results and Proposal For Design MethodologyDocument4 pagesThe Influence of Bond Stress Distribution On Ground Anchor Fixed Length Design. Field Trial Results and Proposal For Design Methodologyaeger2Pas encore d'évaluation

- 2000 Van Mier-Ulfkjaer - Round-Robin Analysis of Over-Reinforced Concrete Beams - Comparison of ResultsDocument10 pages2000 Van Mier-Ulfkjaer - Round-Robin Analysis of Over-Reinforced Concrete Beams - Comparison of ResultsfsimaPas encore d'évaluation

- Punching Shear Tests of Normal-And High-Strength Concrete Flat PlatesDocument12 pagesPunching Shear Tests of Normal-And High-Strength Concrete Flat PlatesHugo Andy SolemanPas encore d'évaluation

- Confinement Du BétonDocument7 pagesConfinement Du Bétonahmed HM100% (1)

- GV Paper Bond Stress Distribution Paris2013Document4 pagesGV Paper Bond Stress Distribution Paris2013Miguel EscobarPas encore d'évaluation

- Non-Linear Behaviour of Concrete Structures Under Severe ImpactDocument8 pagesNon-Linear Behaviour of Concrete Structures Under Severe Impactfoush bashaPas encore d'évaluation

- Communications JNGGDocument16 pagesCommunications JNGGBargaoui Med IdrissPas encore d'évaluation

- Flamb AgeDocument8 pagesFlamb AgeDeghboudj SamirPas encore d'évaluation

- Chapitre 4Document8 pagesChapitre 4Choayb BelghiatPas encore d'évaluation

- Concrete Confined by Steel JacketDocument10 pagesConcrete Confined by Steel JacketRenato MeliPas encore d'évaluation

- Cable AnchorageDocument10 pagesCable AnchorageWP 2-1-PR Katubedda-CESLPas encore d'évaluation

- Torsional Strength of Reinforced Concrete BeamsDocument10 pagesTorsional Strength of Reinforced Concrete BeamsTrần Minh ThuậnPas encore d'évaluation

- Odredivanje Parametara Meh - Loma PDFDocument10 pagesOdredivanje Parametara Meh - Loma PDFPCPCPas encore d'évaluation

- Size Effect and Boundary Conditions in The Brazilian Test - Theoretical AnalysisDocument8 pagesSize Effect and Boundary Conditions in The Brazilian Test - Theoretical AnalysisRoberto UrrutiaPas encore d'évaluation

- Collins - 2003 - On The Relationship Between Stress-Dilatancy Anisotropy and Plastic Dissipation For Granular MaterialsDocument8 pagesCollins - 2003 - On The Relationship Between Stress-Dilatancy Anisotropy and Plastic Dissipation For Granular MaterialsHUGIPas encore d'évaluation

- Un Siècle de Méthodes de Calcul D'écrans de SoutènementDocument21 pagesUn Siècle de Méthodes de Calcul D'écrans de Soutènementfethi42Pas encore d'évaluation

- Thèse Boulkhiout RadhwaneDocument180 pagesThèse Boulkhiout RadhwaneRadhwane BoulkhioutPas encore d'évaluation

- N.Mortensen, J.S.Steenfelt (2001) - Danish Plastic Design of Sheet Pile Walls Revisited in The Light of FEMDocument9 pagesN.Mortensen, J.S.Steenfelt (2001) - Danish Plastic Design of Sheet Pile Walls Revisited in The Light of FEMAnonymous PibYPghPas encore d'évaluation

- Bael Introduction EluDocument22 pagesBael Introduction EluBadr FaroukPas encore d'évaluation

- Wu - 1999 - SEISMIC LATERAL PRESSURES FOR DESIGN OF RIGID WALLSDocument14 pagesWu - 1999 - SEISMIC LATERAL PRESSURES FOR DESIGN OF RIGID WALLSValerioPas encore d'évaluation

- Karstunen - 2010 - Modelling Time-Dependent Behaviour of Murro Test EmbankmentDocument15 pagesKarstunen - 2010 - Modelling Time-Dependent Behaviour of Murro Test EmbankmentHUGIPas encore d'évaluation

- Beton VD1 V2Document14 pagesBeton VD1 V2novakno1Pas encore d'évaluation

- Critical Assessment of Pile Modulus Determination PDFDocument16 pagesCritical Assessment of Pile Modulus Determination PDFLuiz Felipe Goulart FiscinaPas encore d'évaluation

- Homogeneisation de Structures Minces enDocument29 pagesHomogeneisation de Structures Minces enDANDY FranklinPas encore d'évaluation

- JNGG 2002 B PP CheridDocument9 pagesJNGG 2002 B PP CheridJb VenierPas encore d'évaluation

- Analyse Pushover Des Portiques en Béton Armé À Premier Niveau Souple Par Un Modèle de Rotule en FibresDocument6 pagesAnalyse Pushover Des Portiques en Béton Armé À Premier Niveau Souple Par Un Modèle de Rotule en FibresHako KhechaiPas encore d'évaluation

- A Plasticity Model For The Behaviour of Footings On Sand Under Combined LoadingDocument13 pagesA Plasticity Model For The Behaviour of Footings On Sand Under Combined Loadingcarlosenri19Pas encore d'évaluation

- Determination of Rigidity Index For A Shallow Foundation On A Carbonate Clay TillDocument7 pagesDetermination of Rigidity Index For A Shallow Foundation On A Carbonate Clay TillAbed SolimanPas encore d'évaluation

- Qu - 2010 - Evaluation of The Viscous Behaviour of Clay Using Generalised Overstress Viscoplastic TheoryDocument13 pagesQu - 2010 - Evaluation of The Viscous Behaviour of Clay Using Generalised Overstress Viscoplastic TheoryHUGIPas encore d'évaluation

- Ec Gme 321 RDMDocument31 pagesEc Gme 321 RDMJoelle TeukamPas encore d'évaluation

- Résistance Des MatériauxDocument14 pagesRésistance Des MatériauxEl Mehdi BenhimaPas encore d'évaluation

- Comportement Mécanique Des matériaux-TDDocument6 pagesComportement Mécanique Des matériaux-TDNS ADPas encore d'évaluation

- Notes RDM 2GCEIM-1Document118 pagesNotes RDM 2GCEIM-1Jourdain KamufuenketePas encore d'évaluation

- BoukaisDocument3 pagesBoukaisSalah Eddine ChouikhPas encore d'évaluation

- Comportement de PoutreDocument2 pagesComportement de PoutreGbati GBANDIPas encore d'évaluation

- Gelagoti - Koukoulis - Gazetas - 2015 - Estimation of Elastic and Non-Linear Stiffness For Suction CaissonDocument6 pagesGelagoti - Koukoulis - Gazetas - 2015 - Estimation of Elastic and Non-Linear Stiffness For Suction CaissonIWINOSA AGHEDOPas encore d'évaluation

- Galli Prisco 2010Document4 pagesGalli Prisco 2010prashant maliPas encore d'évaluation

- Stress-Dilatancy Relation For Mohr-Coulomb Soils Following A Non-Associated Flow RuleDocument4 pagesStress-Dilatancy Relation For Mohr-Coulomb Soils Following A Non-Associated Flow RuleHUGIPas encore d'évaluation

- Application Aux Calculs de La Charge de Ruine de StructureDocument21 pagesApplication Aux Calculs de La Charge de Ruine de Structurelolitta nora50% (2)

- Manzari Dafalias 1997Document18 pagesManzari Dafalias 1997yuamarbasarahPas encore d'évaluation

- RDM LivreDocument178 pagesRDM LivreYacine OAPas encore d'évaluation

- Analyse Sismique Du Comportement D'une Structure de 7 Étages À Échelle 1 en Béton Armé: Benchmark International NeesDocument8 pagesAnalyse Sismique Du Comportement D'une Structure de 7 Étages À Échelle 1 en Béton Armé: Benchmark International NeesMelkior Jovial Diyani EssoumbaPas encore d'évaluation

- Régimes de RéponseDocument8 pagesRégimes de RéponseAbbas MerouaPas encore d'évaluation

- Seizmički Otporne Armiranobetonske Okvirne Konstrukcije Od Montažnih Elemenata - Ivan TomicicDocument8 pagesSeizmički Otporne Armiranobetonske Okvirne Konstrukcije Od Montažnih Elemenata - Ivan TomicicSlobo_TodorovicPas encore d'évaluation

- Turath GHARIB 06 05 2015Document9 pagesTurath GHARIB 06 05 2015nawel mezighechePas encore d'évaluation

- Baguelin-1977-Theoretical Study of Lateral Reaction Mechanism of PilesDocument30 pagesBaguelin-1977-Theoretical Study of Lateral Reaction Mechanism of Pilesx89ryvz4n2Pas encore d'évaluation

- Nasr - Prévision Probabiliste de La Tenue en Fatigue Polycyclique Des Matériaux À Défauts de Surface - CFM2007-0068Document6 pagesNasr - Prévision Probabiliste de La Tenue en Fatigue Polycyclique Des Matériaux À Défauts de Surface - CFM2007-0068Pierrot Le MarseillaisPas encore d'évaluation

- Size Effect and Boundary Conditions in The Brazilian Test - Experimental VerificationDocument8 pagesSize Effect and Boundary Conditions in The Brazilian Test - Experimental VerificationRoberto UrrutiaPas encore d'évaluation

- Chap 2 Cours Complet EleveDocument3 pagesChap 2 Cours Complet EleveRblhPas encore d'évaluation

- 2 Caractéristiques Mécaniques Du Bois EC5Document7 pages2 Caractéristiques Mécaniques Du Bois EC5Tellache MohamedPas encore d'évaluation

- Manuscrit HDR PDFDocument184 pagesManuscrit HDR PDFOmar ThiamPas encore d'évaluation

- PC 5ème - L5 - Tension ÉlectriqueDocument8 pagesPC 5ème - L5 - Tension Électriquebossio odylon bailletPas encore d'évaluation

- Exposé HydrogéologieDocument21 pagesExposé HydrogéologiePacôme KouadioPas encore d'évaluation

- Alcenes Et AlcynesDocument7 pagesAlcenes Et AlcynesSYLVAIN KOUADIOPas encore d'évaluation

- Chimie (SVT-SMP)Document1 pageChimie (SVT-SMP)Feldher DortPas encore d'évaluation

- 2-Ployaert Qualiroutes - G1 - DefDocument46 pages2-Ployaert Qualiroutes - G1 - DefSadok KzadriPas encore d'évaluation

- Introduction Générale: Plateforme de Gestion Des Déchets MénagersDocument99 pagesIntroduction Générale: Plateforme de Gestion Des Déchets MénagersHD WiemPas encore d'évaluation

- GMEMPLOI Du TEMPSDocument9 pagesGMEMPLOI Du TEMPSYour TechPas encore d'évaluation

- LC 21-010 - CopieDocument6 pagesLC 21-010 - CopieSimon Houde100% (1)

- Analyse GranulometriqueDocument7 pagesAnalyse GranulometriqueWail ZizoPas encore d'évaluation

- 00.Qcm Structure de La MatiereDocument48 pages00.Qcm Structure de La MatiereYassine KootPas encore d'évaluation

- Cours Corrosion - IC 2Document34 pagesCours Corrosion - IC 2thomas yapiPas encore d'évaluation

- Chapitre 1-Generalites Sur Les Solutions ElectrolytiquesDocument15 pagesChapitre 1-Generalites Sur Les Solutions ElectrolytiquesmiassachahdPas encore d'évaluation

- Vitral 120 HSDocument2 pagesVitral 120 HSstemlerPas encore d'évaluation

- Catalogue 2021Document89 pagesCatalogue 2021vsdfsd258Pas encore d'évaluation

- Matériaux de Construction Chapitre1-IntoductionDocument16 pagesMatériaux de Construction Chapitre1-Intoductionkzi itaPas encore d'évaluation

- Devoir Mecanique Des Sols....Document21 pagesDevoir Mecanique Des Sols....previl bodyPas encore d'évaluation

- 07-Rappels de Chimie de 1ère S PDFDocument2 pages07-Rappels de Chimie de 1ère S PDFajy montessouriPas encore d'évaluation

- PoutreDocument1 pagePoutrelamar kreitPas encore d'évaluation

- CCTP Lot1 RL911 RR81 S2Document149 pagesCCTP Lot1 RL911 RR81 S2Nada KhlifPas encore d'évaluation

- Repertoire Des Memoires 2017Document69 pagesRepertoire Des Memoires 2017ilétou inès odjoPas encore d'évaluation

- Géophysique 6Document3 pagesGéophysique 6KoogPas encore d'évaluation