Académique Documents

Professionnel Documents

Culture Documents

CP CPK

Transféré par

shuklahouseTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

CP CPK

Transféré par

shuklahouseDroits d'auteur :

Formats disponibles

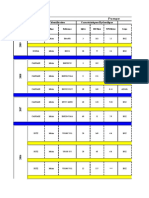

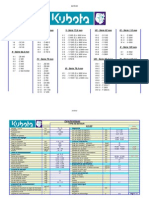

STATISTICAL PROCESS CONTROL STUDY (Centreless Grinder)

PART NAME

:

Excess Fuel Piston

PART NO.

: 9101-244B

SAMPLE SIZE :

50 Nos.

DATA COLLECTION: -

INSTRUMENT :

SPECIFIC

:

OPERATION

:

Mitutoya Micrometer

5.985 + 0.005

TURNED COMPONENT

L.COUNT

:

MACHINE

:

VERNIER CALIPER NO ;

U.T.L.

0.005

Centreless Grinder

5.990

SNO.

10

5.986

5.984

5.985

5.986

5.986

5.987

5.984

5.987

5.985

5.987

5.986

5.984

5.985

5.987

5.986

5.985

5.985

5.984

5.986

5.986

5.986

5.985

5.985

5.985

5.986

5.985

5.985

5.984

5.986

5.986

5.985

5.984

5.987

5.986

5.986

5.986

5.985

5.987

5.985

5.986

5.985

5.985

5.984

5.986

5.986

L.T.L.

5.985

5.985

5.985

5.986

5.986

XLARGE

5.9860

5.9860

5.9870

5.9870

5.9860

5.9860

5.9860

5.9870

5.9870

5.9860

Xmax. =

5.9870

XSMALL

5.9850

5.9840

5.9840

5.9840

5.9840

5.9850

5.9840

5.9840

5.9850

5.9840

Xmin.

5.9840

RANGE

0.0010

0.0010

0.0020

0.0030

0.0020

0.0020

R - BAR =

2

3

4

5.980

1.128

1.880

3.270

1.693

1.020

2.570

2.059

0.730

2.230

2.326

0.590

2.110

NOS.

NOS.

Design Centre ( D )

5.9850

Interval

0.000700

Selecting no. of classes

Starting Point

5.9840

No. of readings

50

Shift Of 'X-BAR' from 'D'

=

=

0.1000

0.000500

5.9826

5.9833

5.9833

5.9840

5.9840

5.9847

5.9847

5.9854

18

25

5.9854

5.9861

19

44

5.9861

5.9868

44

5.9868

5.9875

50

5.9875

5.9882

50

5.9882

5.9889

50

5.9889

5.9896

50

5.9896

5.9903

U.C.L.

L.C.L.

5.9850

CU. FREQ.

5.9826

AVG.

5.9855

FREQ.

5.9819

5.9865

5.9860

INTERVAL

X-CHART

5.9870

X-BAR

5.9845

14

NO. OF PARTS BELOW L.T.L.

5.9852

5.9854

5.9852

Specification Width(S)

=

16

3.270

NO. OF PARTS ABOVE U.T.L.

0.0020

5.9856

18

D4

2.560

0.00210

0.0030

5.9860

18

A2

1.123

5.9852 X - BAR = 5.9855

Index (K)={2 x (D-XBAR)/S} =

0.0030

20

D2

NOS.

5.9854

=

HISTOGRAM

19

SAMPLE

0.0020

0.0031

25/12/2007

NO.OF NON CONFORMING PART =

AVG.

5.9854

Process Width ( P )

5.9856

5.9858

0.010000

DATE:

5.9840

5.9835

12

5.9830

1

10

10

R- CHART

0.10

0.09

0.08

RANGE

0.07

U.C.L.

0.06

L.C.L

0.05

R-BAR

0.04

0.03

5.9826

5.9833

5.9882

5.9889

5.9896

5.9903

0

5.9819

5.9826

5.9840

5.9833

5.9847

5.9840

5.9854

5.9847

5.9861

5.9854

5.9868

5.9861

5.9875

5.9868

5.9875

5.9882

5.9889

5.9896

0.02

OWNER

5.986739

L.C.L.XBAR

5.984261

U.C.L.RBAR

=M15*R11

L.C.L.RBAR

0.01

0.00

PROCESS IS EXCELLENT

CONCLUSION : -

50

U.C.L.XBAR

10

Std.Dev."s"

0.00089

Cp=(S/6s)

1.88080

Cpk={1-K}xCp) =

1.69280

CHECKED BY

APPROVED BY

Mr. Kampta Prasad

Mr. Anish Bagga

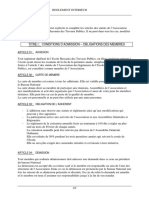

STATISTICAL PROCESS CONTROL STUDY (POWDER COATING)

PART NAME

:

Spacer Washer

PART NO.

: 9101-183

SAMPLE SIZE :

50 Nos.

DATA COLLECTION: -

INSTRUMENT :

SPECIFIC

:

OPERATION

:

Mitutoya Vernier

2.175 + 0.035

TURNED COMPONENT

L.COUNT

:

MACHINE

:

VERNIER CALIPER NO ;

U.T.L.

0.01

2.21

SNO.

10

2.180

2.170

2.170

2.170

2.170

2.170

2.170

2.180

2.180

2.190

2.160

2.180

2.160

2.170

2.190

2.160

2.180

2.170

2.190

2.180

2.180

2.170

2.170

2.170

2.170

2.170

2.170

2.180

2.180

2.190

2.160

2.180

2.160

2.170

2.190

2.160

2.180

2.160

2.170

2.190

2.160

2.180

2.160

2.170

2.190

L.T.L.

2.160

2.180

2.170

2.190

2.180

XLARGE

2.1900

2.1800

2.1900

2.1900

2.1900

2.1800

2.1900

2.1900

2.1900

2.1900

Xmax. =

2.1900

XSMALL

2.1600

2.1700

2.1700

2.1600

2.1600

2.1700

2.1700

2.1600

2.1600

2.1600

Xmin.

2.1600

RANGE

0.0300

0.0100

0.0200

0.0300

0.0300

0.0300

R - BAR =

2

3

4

2.14

3.270

1.020

2.570

2.059

0.730

2.230

2.326

0.590

2.110

NOS.

NOS.

2.1750

Interval

0.006000

Selecting no. of classes

Starting Point

2.1600

No. of readings

50

Shift Of 'X-BAR' from 'D'

=

=

0.0286

0.001000

2.1480

2.1540

2.1540

2.1600

10

10

2.1600

2.1660

10

2.1660

2.1720

18

28

2.1720

2.1780

28

2.1780

2.1840

14

42

2.1840

2.1900

50

2.1900

2.1960

50

2.1960

2.2020

50

2.2020

2.2080

50

2.2080

2.2140

AVG.

U.C.L.

L.C.L.

2.1700

CU. FREQ.

2.1480

2.1850

2.1750

FREQ.

2.1420

2.1900

2.1800

INTERVAL

X-CHART

2.1950

X-BAR

2.1650

2.1600

2.1550

12

1.880

1.693

14

1.128

Design Centre ( D )

14

NO. OF PARTS BELOW L.T.L.

2.1760

2.1720

2.1780

Specification Width(S)

=

16

3.270

NO. OF PARTS ABOVE U.T.L.

0.0300

2.1720

18

D4

2.560

0.02400

0.0300

2.1780

18

A2

1.123

2.1720 X - BAR = 2.1740

Index (K)={2 x (D-XBAR)/S} =

0.0200

20

D2

NOS.

2.1720

=

HISTOGRAM

SAMPLE

0.0100

0.0300

8/10/2007

NO.OF NON CONFORMING PART =

AVG.

2.1760

Process Width ( P )

2.1720

2.1720

0.070000

DATE:

Automate

2.1500

2.1450

10

10

10

8

R- CHART

8

0.10

0.09

0.08

RANGE

0.07

U.C.L.

0.06

L.C.L

0.05

R-BAR

0.04

0.03

2.1480

2.1540

2.1960

2.2020

2.2080

2.2140

0

2.1420

2.1480

2.1600

2.1540

2.1660

2.1600

2.1720

2.1660

2.1780

2.1720

2.1840

2.1780

2.1900

2.1840

2.1900

2.1960

2.2020

2.2080

0.02

OWNER

2.18816

L.C.L.XBAR

2.159840

U.C.L.RBAR

=M15*R11

L.C.L.RBAR

0.01

0.00

PROCESS IS GOOD BUT STILL IMPROVEMENT IS REQUIRED

CONCLUSION : -

50

U.C.L.XBAR

10

Std.Dev."s"

0.00990

Cp=(S/6s)

1.17880

Cpk={1-K}xCp) =

1.14510

CHECKED BY

APPROVED BY

MS REKHA PATIL

MR SHYAM MAGAR

Vous aimerez peut-être aussi

- E848170000 D1A1521206 AmdecDocument7 pagesE848170000 D1A1521206 AmdeckhaledPas encore d'évaluation

- 2-8-MSA Analy System MesureDocument57 pages2-8-MSA Analy System Mesureelyes elyesPas encore d'évaluation

- Value Stream MappingDocument31 pagesValue Stream MappingKhalid HajirPas encore d'évaluation

- Classeur1 (MSA&MSP ET Traitement de Non Conf)Document11 pagesClasseur1 (MSA&MSP ET Traitement de Non Conf)Trabelsi MoncefPas encore d'évaluation

- PR htl4017-4014 Tier3-Tier2 E06.08Document577 pagesPR htl4017-4014 Tier3-Tier2 E06.08michaelPas encore d'évaluation

- Dauphin n3Document11 pagesDauphin n3kushankvjPas encore d'évaluation

- Ac Acs Plus 7-11-15s+opt11Document52 pagesAc Acs Plus 7-11-15s+opt11civodulPas encore d'évaluation

- 04 - Tds - Analyse de ParetoDocument7 pages04 - Tds - Analyse de ParetoSalah Eddine Chouikh100% (1)

- Bosch Efi - TechservicepartsDocument18 pagesBosch Efi - TechservicepartsdetworkshopPas encore d'évaluation

- CR Centro SL 50 99 KatDocument15 pagesCR Centro SL 50 99 KatGuse MarcelPas encore d'évaluation

- Liste de Pièces 2Document2 pagesListe de Pièces 2Walid RzigPas encore d'évaluation

- 10-2 - TD - Indicateurs en Maintenance - Analyse de ParetoDocument8 pages10-2 - TD - Indicateurs en Maintenance - Analyse de ParetoHouciin El Maalem67% (3)

- Spare Parts Karcher - MISTRAL DS 2690 TDocument15 pagesSpare Parts Karcher - MISTRAL DS 2690 TosenlopPas encore d'évaluation

- Moteur lj276mt2Document18 pagesMoteur lj276mt2Hervé Dorvaux100% (1)

- RT EngineeringDataDocument17 pagesRT EngineeringDataCristian Contreras PerezPas encore d'évaluation

- Valve de RemplissageDocument8 pagesValve de RemplissageWalid RzigPas encore d'évaluation

- 97-04 Aixam 400 PDFDocument52 pages97-04 Aixam 400 PDFlucian_201050% (2)

- C-List 500 H A3 SpeedDocument12 pagesC-List 500 H A3 SpeedtechlabPas encore d'évaluation

- 724 - 904 - Catalogue de Pieces de RechangeDocument73 pages724 - 904 - Catalogue de Pieces de RechangenicolasPas encore d'évaluation

- TOUT Equipement 280SLCDocument9 pagesTOUT Equipement 280SLCALBATROSPas encore d'évaluation

- Dodge Tigear 2 20Document8 pagesDodge Tigear 2 20eecsacPas encore d'évaluation

- Spare Parts List WMF1400Document47 pagesSpare Parts List WMF1400bv_36100% (1)

- Catalogue Mot Perkins1104c-44 (7t)Document150 pagesCatalogue Mot Perkins1104c-44 (7t)goxmad100% (1)

- Moteur - Briggs Stratton - 31a607 0125 b1 - Vue Eclatee Liste Des PiecesDocument25 pagesMoteur - Briggs Stratton - 31a607 0125 b1 - Vue Eclatee Liste Des PiecesBenoît MARTINPas encore d'évaluation

- PSRPT 2018-04-17 16.58.22Document6 pagesPSRPT 2018-04-17 16.58.22semahPas encore d'évaluation

- 12H802-1824-B1 Sélection: Cames, Arbre À Cames, Vilebrequin, Cylindre, Carter D'huile Moteur, Kit/joints, Graissage, Groupe deDocument21 pages12H802-1824-B1 Sélection: Cames, Arbre À Cames, Vilebrequin, Cylindre, Carter D'huile Moteur, Kit/joints, Graissage, Groupe delazhorPas encore d'évaluation

- Mahle 2010 AP CompleteDocument20 pagesMahle 2010 AP CompleteAba AbbyPas encore d'évaluation

- Coupleur HydrauliqueDocument3 pagesCoupleur HydrauliqueAdnan Abu MohamedPas encore d'évaluation

- MXL0Document13 pagesMXL0semahPas encore d'évaluation

- Emerson PDFDocument196 pagesEmerson PDFLuis ArmandoPas encore d'évaluation

- Ton Kho 22-6-2012Document170 pagesTon Kho 22-6-2012luongan1983Pas encore d'évaluation

- N° Référence DésignationDocument8 pagesN° Référence Désignationakram aissaPas encore d'évaluation

- S07 Poclain Multidisk Brakes MS18 BDocument11 pagesS07 Poclain Multidisk Brakes MS18 BMoises GmPas encore d'évaluation

- Atf 80 4Document17 pagesAtf 80 4Otto Heinrich WehmannPas encore d'évaluation

- Peças de Reposição - TFC46Document668 pagesPeças de Reposição - TFC46Roberio Barros100% (2)

- MR353VELSATIS1Document474 pagesMR353VELSATIS1phil_turboPas encore d'évaluation

- RAPPORT DE MISSION TVX GS2 de Medouneu À MITZIC V2 (Récupéré)Document5 pagesRAPPORT DE MISSION TVX GS2 de Medouneu À MITZIC V2 (Récupéré)ntllionnelPas encore d'évaluation

- Whirlpool Ach 807 808-01 (ET)Document7 pagesWhirlpool Ach 807 808-01 (ET)Raluca Georgiana ManolePas encore d'évaluation

- MR 295 Clio 1Document430 pagesMR 295 Clio 1Lina Calderon100% (2)

- Base Des Donn EsDocument43 pagesBase Des Donn EsAhmed BoussoffaraPas encore d'évaluation

- 02-SQF 3a-10Document12 pages02-SQF 3a-10zhonghaonigerPas encore d'évaluation

- (91 07 426 08) Groupe D'entrainement, Premonte - 20240330 - 110541Document3 pages(91 07 426 08) Groupe D'entrainement, Premonte - 20240330 - 110541ISMAIL GHABIAPas encore d'évaluation

- Einstellpotentiometer Ke-Jetronic 2017Document9 pagesEinstellpotentiometer Ke-Jetronic 2017PrudencioTeodosioPas encore d'évaluation

- Gavina GT F Confort InstaladorDocument18 pagesGavina GT F Confort Instaladorjuan carlosPas encore d'évaluation

- Service Bulletin HY30 3207 EU 147 WebDocument24 pagesService Bulletin HY30 3207 EU 147 WebthierrylindoPas encore d'évaluation

- Unite 25 Manuel OpératoireDocument201 pagesUnite 25 Manuel OpératoireAbdessalem BougoffaPas encore d'évaluation

- Inspection Report LHM 550 Serial Number 141254 (Enregistré Automatiquement)Document9 pagesInspection Report LHM 550 Serial Number 141254 (Enregistré Automatiquement)Gorgui Souleymane DIENGPas encore d'évaluation

- P15A0, P15A1, P15A8 Pression D'huile PSADocument10 pagesP15A0, P15A1, P15A8 Pression D'huile PSAChristian MillonPas encore d'évaluation

- PCT 339817jDocument25 pagesPCT 339817jjosuePas encore d'évaluation

- Norma TecnicaDocument2 235 pagesNorma Tecnicaivan0% (1)

- Moteurs Asynchrone Ie4Document8 pagesMoteurs Asynchrone Ie4YùriJiroùÈchiroPas encore d'évaluation

- 1000 Entretien Transmission BT808Document2 pages1000 Entretien Transmission BT808Hassan NouwaliPas encore d'évaluation

- 09 - Pieces de Rechange Iveco N 67 MsaeDocument79 pages09 - Pieces de Rechange Iveco N 67 MsaeOusmane DiakitéPas encore d'évaluation

- Vmi Berto Italia Spiral Mixer Spi 400 1998 ManualDocument29 pagesVmi Berto Italia Spiral Mixer Spi 400 1998 ManualjavierPas encore d'évaluation

- Aprietes KubotaDocument78 pagesAprietes KubotaJOSEALBERICH80% (5)

- 13 Master GazDocument63 pages13 Master GazchkzaPas encore d'évaluation

- 020581-CPFG05-49ER-2311 Volume II Système 23-27-38 Manuel Opératoire Pour TurbinesDocument432 pages020581-CPFG05-49ER-2311 Volume II Système 23-27-38 Manuel Opératoire Pour TurbinesAbdessalem BougoffaPas encore d'évaluation

- Kaltstartventile 2022Document9 pagesKaltstartventile 2022Victor ZhicayPas encore d'évaluation

- Eta252 511Document20 pagesEta252 511José F. MartinezPas encore d'évaluation

- DR - Antidemarrage Citroen Et RenaultDocument6 pagesDR - Antidemarrage Citroen Et Renaultaymendab100% (1)

- LE CIRCUIT IMPRIME .-ConvertiDocument3 pagesLE CIRCUIT IMPRIME .-Convertiسعيد تامرPas encore d'évaluation

- Reglement Interieur AiehtpDocument5 pagesReglement Interieur AiehtpTaha BenPas encore d'évaluation

- Inf1600 Devoir 01Document3 pagesInf1600 Devoir 01Ahmed GafsiPas encore d'évaluation

- Therm - Stockage Et Aliment. Gaz FuelDocument72 pagesTherm - Stockage Et Aliment. Gaz FuelNizarChouchenePas encore d'évaluation

- Introduction À La Notion D'ordiDocument2 pagesIntroduction À La Notion D'ordikabi6713Pas encore d'évaluation

- Bac-Blanc LGM - 2021Document5 pagesBac-Blanc LGM - 2021Sébastien ONDO MINKOPas encore d'évaluation

- BNT Is Normal 2021Document25 pagesBNT Is Normal 2021YS ConsultingPas encore d'évaluation

- Classif CoursDocument86 pagesClassif Courskistidi33Pas encore d'évaluation

- LINFO1101Document10 pagesLINFO1101itsamePas encore d'évaluation

- Boulonnerie Visserie CoursDocument10 pagesBoulonnerie Visserie CoursRizouga AbdallahPas encore d'évaluation

- Planification D'urgenceDocument20 pagesPlanification D'urgenceABADI NAHIDPas encore d'évaluation

- 796Document8 pages796Simo SimoPas encore d'évaluation

- Les Abaques Multiplaz 3500Document5 pagesLes Abaques Multiplaz 3500Nacer MezghichePas encore d'évaluation

- Descriprion Procédé de PlâtreDocument3 pagesDescriprion Procédé de PlâtreErick basiluaPas encore d'évaluation

- PPA Solutions DownloadDocument16 pagesPPA Solutions DownloadSam BroisePas encore d'évaluation

- VERDITDocument27 pagesVERDITAya SePas encore d'évaluation

- Teufel ShopDocument1 pageTeufel ShopCaractère ExclusivePas encore d'évaluation

- A ImprimerDocument14 pagesA ImprimerhsnghhPas encore d'évaluation

- These Finale Gravé Sur DisqueDocument146 pagesThese Finale Gravé Sur DisqueMarie DaguidamPas encore d'évaluation

- Courroies Dentées ATN 1207Document8 pagesCourroies Dentées ATN 1207Claudine Elisseev100% (2)

- Script D'appel EntrantDocument2 pagesScript D'appel EntrantAudry Lucious Lyon100% (1)

- GACDocument2 pagesGACTelli Noel theaPas encore d'évaluation

- Communiquer Marjane Sapino - VFDocument2 pagesCommuniquer Marjane Sapino - VFFati FlourPas encore d'évaluation

- CV Ferdinand KAHENGA E VDocument2 pagesCV Ferdinand KAHENGA E VAnonymous KrNlWdkzcPas encore d'évaluation

- CNOM 2012 30 Juin 2013Document92 pagesCNOM 2012 30 Juin 2013micahloisvalmoriaPas encore d'évaluation

- TD Estimation 2022 2023Document2 pagesTD Estimation 2022 2023Mariam GueyePas encore d'évaluation

- Module 1 1 Gestion Des Investissements - Et - NVDocument30 pagesModule 1 1 Gestion Des Investissements - Et - NVTasnime NissadPas encore d'évaluation

- Application Mobile Netbeans PDFDocument18 pagesApplication Mobile Netbeans PDFABDELKADER GUENAIZIPas encore d'évaluation

- Ex06 - Etage D'adaptationDocument6 pagesEx06 - Etage D'adaptationAissa KalachePas encore d'évaluation