Académique Documents

Professionnel Documents

Culture Documents

P-213 Parker Temp Press Chart PDF

Transféré par

Иван ЧечушковTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

P-213 Parker Temp Press Chart PDF

Transféré par

Иван ЧечушковDroits d'auteur :

Formats disponibles

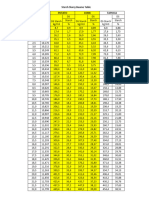

Pressure-Temperature Chart at Sea Level

TEMPERATURE °F

PSIG REFRIGERANT - (REFRIGERANT DESIGNATION)

22 (V) 134a (J) 410A (Z) 507 (S) 717 (A) 438A (V)

5* -48 -22 -67 -59 -35 -40

4* -47 -21 -66 -58 -33 -38

3* -46 -19 -64 -56 -32 -37

2* -44 -18 -63 -55 -30 -36

1* -43 -16 -62 -53 -29 -34

0 -41 -15 -61 -52 -28 -33

1 -39 -12 -58 -50 -26 -31

2 -36 -10 -56 -47 -23 -28

3 -34 -7 -54 -45 -21 -26

4 -32 -5 -52 -43 -19 -24

5 -30 -3 -50 -41 -17 -22

6 -28 -1 -48 -39 -15 -20

7 -26 1 -46 -37 -13 -18

8 -24 3 -45 -35 -12 -16

9 -22 5 -43 -33 -10 -14

10 -20 7 -41 -32 -8 -13

11 -19 8 -40 -30 -7 -11

12 -17 10 -38 -28 -5 -9

13 -15 12 -37 -27 -4 -8

14 -14 13 -35 -25 -2 -6

15 -12 15 -34 -24 -1 -5

16 -11 16 -32 -22 0 -3

17 -9 18 -31 -21 2 -2

18 -8 19 -30 -19 3 -1

19 -7 21 -29 -18 4 1

20 -5 22 -27 -17 6 2

21 -4 24 -26 -16 7 3

22 -3 25 -25 -14 8 5

23 -1 26 -24 -13 9 6

24 0 27 -23 -12 10 7

25 1 29 -21 -11 11 8

26 2 30 -20 -9 12 9

27 4 31 -19 -8 14 10

28 5 32 -18 -7 15 12

29 6 33 -17 -6 16 13

30 7 35 -16 -5 17 14

31 8 36 -15 -4 18 15

32 9 37 -14 -3 19 16

33 10 38 -13 -2 20 17

34 11 39 -12 -1 20 18

35 12 40 -11 0 21 19

36 13 41 -10 1 22 20

BUBBLE POINT

37 14 42 -10 2 23 21

38 15 43 -9 3 24 22

39 16 44 -8 4 25 23

40 17 45 -7 5 26 24

42 19 47 -5 7 28 25

44 21 49 -4 9 29 27

46 23 51 -2 10 31 29

48 24 52 0 12 32 30

50 26 54 1 14 34 32

52 28 56 3 15 35 34

54 29 57 4 17 37 35

56 31 59 6 18 38 37

58 32 60 7 20 40 38

60 34 62 8 21 41 40 30

62 35 64 10 23 42 41 32

64 37 65 11 24 44 42 33

66 38 66 12 26 45 44 34

68 40 68 14 27 46 45 36

70 41 69 15 28 47 46 37

72 42 71 16 30 49 48 38

74 44 72 17 31 50 49 40

76 45 73 18 32 51 50 41

78 46 75 20 33 52 52 42

80 48 76 21 35 53 53 43

85 51 79 24 38 56 56 46

90 54 82 26 40 59 59 49

95 56 85 29 43 61 61 52

100 59 88 31 46 63 64 55

105 62 90 34 48 66 66 58

110 64 93 36 51 68 69 60

115 67 96 38 53 70 71 63

120 69 98 41 56 73 65

125 72 100 43 58 75 67

130 74 103 45 60 77 70

135 76 105 47 63 79 72

DEW POINT

140 78 107 49 65 81 74

145 81 109 51 67 82 76

150 83 112 53 69 84 78

155 85 114 54 71 86 80

160 87 116 56 73 88 82

165 89 118 58 75 90 84

170 91 120 60 77 91 86

175 93 122 61 78 93 88

180 94 123 63 80 95 90

185 96 125 65 82 96 91

190 98 127 66 84 98 93

195 100 129 68 85 99 95

200 101 130 69 87 101 97

205 103 132 71 89 102 98

210 105 134 72 90 104 100

220 108 137 75 93 107 103

230 111 140 78 96 109 106

240 114 143 81 99 112 109

250 117 146 84 102 115 112

260 120 149 86 105 117 115

275 124 153 90 109 121 119

290 128 157 94 113 124 123

305 132 161 97 117 128 127

320 136 165 100 120 131 130

335 139 169 104 124 134 134

350 143 172 107 127 137 137

365 146 176 110 130 140 141

380 150 179 113 133 143 144

400 154 183 117 138 147 148

420 158 187 120 141 150 152

440 162 191 124 145 154 156

460 166 195 127 149 157 160

480 170 198 130 152 160 164

500 173 202 134 156 163 167

* Inches mercury below one atmosphere

MAKE A SYSTEMATIC ANALYSIS

Based on the complaint and measurements taken

Changing Parts Might Be The First Reaction

BUT... SuctioHigh

n Pres

1. May not be necessary and... sure

Low

2. Does not always solve the problem Superh

eat

SUPERHEAT AND POSSIBLE CAUSES

SUCTION PRESSURE 1. Oversized valve

symptoms can provide the real cause 2. TEV seat leak

High eat 3. Low superheat adjustment

Superh 4. Bulb installation

Low ssure a. Poor thermal contact

n Pre b. Warm location

Suctio 5. Wrong thermostatic charge

POSSIBLE CAUSES 6. Bad compressor – low capacity

7. Moisture, dirt, wax

1. Moisture, dirt, wax 8. Incorrectly located external equalizer

2. Undersized valve

3. High superheat adjustment

4. Gas charge condensation C R A CK

5. Dead thermostatic element charge

6. Wrong thermostatic charge Low ssure Low

Pre Superh

7. Evaporator pressure drop — S uction eat

no external equalizer

8. External equalizer location POSSIBLE CAUSES

9. Restricted or capped external equalizer 1. Low load

10. Low refrigerant charge a. Not enough air

11. Liquid line vapor b. Dirty air filters

a. Vertical lift c. Air too cold

b. High friction loss d. Coil icing

c. Long or small line 2. Poor air distribution

d. Plugged drier or strainer 3. Poor refrigerant distribution

12. Low pressure drop across valve 4. Improper compressor-evaporator balance

a. Same as #11 above 5. Evaporator oil logged

b. Undersized distributor nozzle or circuits 6. Flow from one TEV affecting

c. Low condensing temperature another’s bulb

OBTAIN SUCTION PRESSURE

68 PSIG (at bulb)

Parker Hannifin Corporation

1-800-742-2681

www.parker.com/coolparts

© 2012 by Parker Hannifin Corporation • Broadview, IL 60155 Form P-213-612

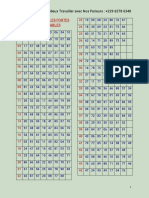

Pressure-Temperature Chart at Sea Level

TEMPERATURE °F

PSIG REFRIGERANT - (REFRIGERANT DESIGNATION)

401A (J) 404A (S) 407A (V) 407C (V) 407F (V) 422D (V)

5* -24 -57 -44 -41 -46 -44

4* -23 -55 -43 -39 -45 -42

3* -21 -54 -41 -38 -43 -41

2* -20 -52 -40 -36 -42 -40

1* -18 -51 -39 -35 -41 -38

0 -17 -50 -37 -34 -39 -37

1 -14 -47 -35 -31 -37 -35

2 -12 -45 -33 -29 -35 -32

3 -9 -43 -31 -27 -33 -30

4 -7 -41 -28 -25 -30 -28

5 -5 -39 -26 -23 -28 -26

6 -3 -37 -25 -21 -27 -24

7 -1 -35 -23 -19 -25 -22

8 1 -33 -21 -17 -23 -20

9 3 -31 -19 -15 -21 -18

10 5 -29 -17 -14 -20 -17

11 7 -28 -16 -12 -18 -15

12 8 -26 -14 -11 -16 -13

13 10 -24 -13 -9 -15 -12

14 12 -23 -11 -7 -13 -10

15 13 -21 -10 -6 -12 -9

16 15 -20 -8 -5 -11 -7

17 16 -19 -7 -3 -9 -6

18 18 -17 -6 -2 -8 -5

19 19 -16 -4 -1 -7 -3

20 21 -15 -3 1 -5 -2

21 22 -13 -2 2 -4 -1

BUBBLE POINT

22 23 -12 -1 3 -3 0

23 25 -11 1 4 -2 2

24 26 -10 2 6 0 3

25 27 -8 3 7 1 4

26 28 -7 4 8 2 5

27 30 -6 5 9 3 6

28 31 -5 6 10 4 7

29 32 -4 7 11 5 9

30 33 -3 8 12 6 10

31 34 -2 9 13 7 11

32 35 -1 10 14 8 12

33 36 0 11 15 9 13

34 37 1 12 16 10 14

35 38 29 2 13 17 11 15

36 39 30 3 14 18 12 16

BUBBLE POINT

37 41 31 4 15 19 13 17

38 42 32 5 16 20 14 18

BUBBLE POINT

39 43 33 6 17 21 15 18

40 44 34 7 18 22 16 19

BUBBLE POINT

42 45 36 9 20 24 17 21

BUBBLE POINT

44 47 38 11 21 25 19 23

46 49 40 13 23 27 21 25

BUBBLE POINT

48 51 42 14 25 29 22 26

50 53 43 16 26 30 24 28

52 54 45 17 28 32 25 30

54 56 47 19 29 33 27 31

56 58 48 21 31 35 28 33

58 59 50 22 32 36 30 34

60 61 52 24 34 38 31 36 29

62 62 53 25 35 39 33 37 31

64 64 55 26 36 41 29 34 38 32

66 65 56 28 38 42 31 35 40 33

68 67 58 29 39 29 43 32 37 41 35

70 68 59 30 30 40 30 45 34 38 42 36

72 69 61 32 31 42 32 46 35 39 44 37

74 71 62 33 32 43 33 47 36 40 30 45 39

76 63 34 33 44 34 48 37 42 32 46 40

78 65 36 35 45 35 50 39 43 33 47 41

80 66 37 36 47 37 51 40 44 34 49 43

85 69 40 39 49 40 54 43 47 37 52 46

90 72 43 42 52 42 56 46 50 40 54 49

DEW POINT

95 75 45 45 55 45 59 48 52 43 57 51

100 78 48 47 57 48 62 51 55 45 60 54

105 81 51 50 60 50 64 54 57 48 62 57

110 84 53 52 62 53 67 56 60 50 65 59

115 86 56 55 65 55 69 59 62 53 67 62

120 89 58 57 67 58 71 61 64 55 70 64

125 91 60 60 69 60 63 66 57 72 67

130 94 63 62 71 62 65 69 59 69

135 96 65 64 64 68 71 61 71

140 98 67 66 66 70 64 73

145 101 69 68 68 72 66 75

DEW POINT

150 103 71 70 70 74 68 77

DEW POINT

155 105 72 72 76 69 79

DEW POINT

160 107 74 74 78 71 81

DEW POINT

165 109 76 76 80 73 83

170 111 78 78 82 75 85

DEW POINT

175 113 80 80 83 77 87

180 115 82 82 85 79 89

185 117 83 83 87 80 91

190 119 85 85 89 82 93

195 121 87 87 90 84 94

200 123 89 88 92 85 96

205 124 90 90 94 87 98

210 126 92 92 95 88 99

220 130 95 95 98 92 103

230 133 98 98 101 95 106

240 136 101 101 104 97 109

250 139 104 104 107 100 112

260 142 107 106 110 103 114

275 147 111 110 114 107 119

290 151 115 114 118 111 122

305 155 118 118 122 114 126

320 159 122 121 125 118 130

335 163 125 125 129 121 134

350 166 129 128 132 125 137

365 170 132 132 135 128 140

380 174 135 135 139 131 144

400 178 139 139 143 135 148

420 182 143 143 147 139 152

440 187 147 147 151 143 156

460 191 151 150 154 146 159

480 195 154 154 158 150 163

500 198 157 157 161 153 166

* Inches mercury below one atmosphere

P-H DIAGRAM — BLENDS

Bubble Point Refrigeration Cycle

Dew Point

Lines of Constant Temperature

To detemine superheat, use Dew Point values. To determine subcooling, use Bubble Point values.

APPROXIMATE PRESSURE CONTROL SETTINGS

Pressure - Pounds Per Square Inch Gauge

REFRIGERANT

TEMPERATURE EVAPORATOR

APPLICATION 22 134a 404A 507

RANGE (°F) TD (°F)

Out In Out In Out In Out In

Beverage Cooler

Floral Cooler 35 to 38 15 41 66 17 33 53 82 56 86

Produce Cooler

Smoked Meat Cooler

Meat Reach Thru

32 to 35 15 38 62 15 30 49 77 52 81

Service Deli

Seafood

Multi-Deck Fresh Meat 26 to 29 15 32 54 11 25 42 68 45 72

Frozen Glass Door

-10 to 0 10 9 24 - - 15 33 16 35

Frozen Walk-In

Frozen Ice Cream

-30 to -20 10 0 10 - - 4 16 4 18

Frozen Food - Open Type

Pressure control settings assume a suction line pressure loss equivalent to 2°F.

CARRYING CAPACITY OF REFRIGERATION LINES

Tons of Refrigeration - 200 Feet Equivalent Pipe Length

REFRIGERANT REFRIGERANT

IRON

TYPE L 22 134a 404A / 507 717 (Ammonia)

PIPE

COPPER TUBE Liquid Suction Liquid Suction Liquid Suction SCHEDULE Liquid Suction

SIZE

O.D. Inches Line Line Line Line Line Line Line Line

Inches

20°F Evap. 20°F Evap. -20°F Evap. 20°F Evap.

3/8 0.99 0.09 0.73 0.06 0.71 0.04 3/8 80 10.2 0.41

1/2 2.37 0.23 1.77 0.13 1.71 0.10 1/2 80 20.1 0.81

5/8 4.48 0.43 3.36 0.25 3.23 0.18 3/4 80 45.5 1.85

7/8 11.9 1.13 8.97 0.67 8.58 0.49 1 80 89.4 3.64

1-1/8 24.3 2.30 18.3 1.36 17.5 0.99 1-1/4 80 192 7.84

1-3/8 42.6 4.02 32.2 2.38 30.6 1.74 1-1/2 80 293 12.0

1-5/8 67.6 6.37 51.1 3.78 48.4 2.76 2 40 683 28.0

2-1/8 141 13.2 107 7.88 101 5.74 2-1/2 40 1090 44.7

2-5/8 250 23.4 190 14.0 179 10.2 3 40 1930 79.1

3-1/8 400 37.5 304 22.4 286 16.3 3-1/2 40 2820 116

3-5/8 595 55.7 453 33.3 425 24.2 4 40 3930 162

4-1/8 841 78.7 641 47.0 600 34.2 5 40 7100 292

Refrigerants 22, 134a, 404A, and 507 values are based on 100°F liquid temperature and the stated evaporator temperature.

Refrigerant 717 (ammonia) values are based on 86°F liquid temperature and 20°F evaporator temperature. Both suction

and liquid line values are based on a pressure drop equivalent to 1°F change in saturation temperature. For additional

information on refrigerant line sizing, consult ASHRAE’s Refrigeration Handbook or equipment manufacturer.

Vous aimerez peut-être aussi

- Normas y Tablas de Conversion WAIS IV PDFDocument25 pagesNormas y Tablas de Conversion WAIS IV PDFGaby Alcaraz88% (8)

- Acleis NGLM 24-7mDocument40 pagesAcleis NGLM 24-7mSeovicPas encore d'évaluation

- IBM-313 MarksDocument3 pagesIBM-313 Marksgopal_svsemails8998100% (1)

- r454b PT Chart PDFDocument5 pagesr454b PT Chart PDFRachel Lam BarbosaPas encore d'évaluation

- Sporlan PT Chart PDFDocument2 pagesSporlan PT Chart PDFtanweer khan100% (2)

- Tabela de Arqueação Teórica: Capacidade Nominal: 15.333 LitrosDocument1 pageTabela de Arqueação Teórica: Capacidade Nominal: 15.333 LitrosKlayton AquinoPas encore d'évaluation

- Aide Mémoire: Manuel À L'usage Du Personnel SpécialiséDocument112 pagesAide Mémoire: Manuel À L'usage Du Personnel SpécialiséSibony yanivPas encore d'évaluation

- 04 Neos Unit Operation-Reva FreDocument14 pages04 Neos Unit Operation-Reva FreHoussemTunisinoPas encore d'évaluation

- Moulinex Ovatio 3 Duo PressDocument14 pagesMoulinex Ovatio 3 Duo PressLeGalizienPas encore d'évaluation

- SERVICE 3501i-4501i-5501iDocument1 188 pagesSERVICE 3501i-4501i-5501iabm503181Pas encore d'évaluation

- 675 SIP Regional Prodigy 2023 Abacus Question Paper For Foundation Level 1 Below 9 YrsDocument141 pages675 SIP Regional Prodigy 2023 Abacus Question Paper For Foundation Level 1 Below 9 YrsSouvik MondalPas encore d'évaluation

- 95 Resume Meca 2019Document6 pages95 Resume Meca 2019Hicham ZghariPas encore d'évaluation

- C5autovolt PDFDocument61 pagesC5autovolt PDFilja5nill100% (2)

- N2X7FDocument60 pagesN2X7FbeezeinPas encore d'évaluation

- Starch Bume DensityDocument4 pagesStarch Bume DensityKebo NdigarPas encore d'évaluation

- Catalog Fitinguri CompresiuneDocument8 pagesCatalog Fitinguri CompresiunerudyschmidtPas encore d'évaluation

- Actarit Iguratimod Tablets ExcelDocument21 pagesActarit Iguratimod Tablets Excelmamatha mammuPas encore d'évaluation

- Starch Slurry Baume TableDocument4 pagesStarch Slurry Baume TableKebo NdigarPas encore d'évaluation

- Tabla de Presión-TemperaturaDocument3 pagesTabla de Presión-TemperaturaPillo Ing100% (1)

- Linea 92 Cuneo Dronero Roccabruna: TPL Extraurbano ProvinciaDocument2 pagesLinea 92 Cuneo Dronero Roccabruna: TPL Extraurbano ProvinciaTomaso AlifrediPas encore d'évaluation

- Verins Cnomo IsoDocument21 pagesVerins Cnomo Isoyouri59490Pas encore d'évaluation

- Résultats Duathlon S Relais Nevers 2022Document1 pageRésultats Duathlon S Relais Nevers 2022Jean-Baptiste DURANDPas encore d'évaluation

- MF ACT002033A FR PreviewDocument31 pagesMF ACT002033A FR PreviewwiqueprofiroPas encore d'évaluation

- Maintenance MRS 3.4 - N99 58ADocument56 pagesMaintenance MRS 3.4 - N99 58AabdourahouPas encore d'évaluation

- Manuel DR1524manuel DR1524Document81 pagesManuel DR1524manuel DR1524Kire Mitrovski100% (1)

- Interclisa MACV034-054Document2 pagesInterclisa MACV034-054David Lemos SanchezPas encore d'évaluation

- MCD II Centora, Calydra Delta-Notice D'installation Et D'emplDocument12 pagesMCD II Centora, Calydra Delta-Notice D'installation Et D'emplLahouari FatahPas encore d'évaluation

- TtableDocument2 pagesTtableN APas encore d'évaluation

- DA58 FRDocument90 pagesDA58 FRBout de FicelPas encore d'évaluation

- Gestão de Banca Guilherme DelpinoDocument10 pagesGestão de Banca Guilherme Delpinocharles carvalhoPas encore d'évaluation

- DieciDocument82 pagesDieciDaniel Bravo HernandezPas encore d'évaluation

- ASmet - Śrub Z Łbem Sześciokątnym Z Gwintem Na Całej Długości Trzpienia - PN-EN ISO 4017 PDFDocument4 pagesASmet - Śrub Z Łbem Sześciokątnym Z Gwintem Na Całej Długości Trzpienia - PN-EN ISO 4017 PDFSzymonPas encore d'évaluation

- C12EX1Document2 pagesC12EX1YoussefBharPas encore d'évaluation

- HUAGUANG R600aDocument1 pageHUAGUANG R600aCesar Visamón HistolPas encore d'évaluation

- Fraction Conversion ChartDocument2 pagesFraction Conversion ChartpptmnltPas encore d'évaluation

- Tableau Boules Fortes IncontournablesDocument2 pagesTableau Boules Fortes IncontournablesGénéral KalacutaPas encore d'évaluation

- Buderus Logamatic 2107 UtilisateurDocument68 pagesBuderus Logamatic 2107 Utilisateurheugen.marcoPas encore d'évaluation

- Pone 0026729 s001Document858 pagesPone 0026729 s001Sukrisdianto DiantoPas encore d'évaluation

- Cataloguefr2009 Sumer NR80Document108 pagesCataloguefr2009 Sumer NR80Stephane ChevalierPas encore d'évaluation

- Manual TecnicoDocument67 pagesManual TecnicoYolwin FloresPas encore d'évaluation

- Bticino CatalogueDocument252 pagesBticino CatalogueMoustapha SeyePas encore d'évaluation

- CA.02.00 Catalogue OTEC 2020Document35 pagesCA.02.00 Catalogue OTEC 2020loic100% (2)

- Manuel Technique SurveyEVO Close Control 2.0 PDFDocument108 pagesManuel Technique SurveyEVO Close Control 2.0 PDFsig-hanaPas encore d'évaluation

- Sporlan P&T ChartDocument2 pagesSporlan P&T ChartMuhammadAsimPas encore d'évaluation

- Los Números Enteros - Juego de Cálculo - Cartones - OnMAT 1Document3 pagesLos Números Enteros - Juego de Cálculo - Cartones - OnMAT 1jayjayalves02Pas encore d'évaluation

- Sporlan TP ChartDocument2 pagesSporlan TP Chartcalvin.bloodaxe4478100% (1)

- 1 Data SPTDocument3 pages1 Data SPTTikaPas encore d'évaluation

- A-Gas Kirby PT Chart - Tabela - Pressao - Temp - GasDocument1 pageA-Gas Kirby PT Chart - Tabela - Pressao - Temp - GasWeimannPas encore d'évaluation

- Deret Angka 01Document1 pageDeret Angka 01Latihan SoalpsikotestPas encore d'évaluation

- Faham e Islam (Book) - By: DR - Mufti Abdulwahid SahabDocument209 pagesFaham e Islam (Book) - By: DR - Mufti Abdulwahid Sahabthebestislam_comPas encore d'évaluation

- Total Jumlah Kunjungan Jan - AgtsDocument3 pagesTotal Jumlah Kunjungan Jan - Agtsibnu hajarPas encore d'évaluation

- AbacoDocument3 pagesAbacoENSIL AMERICASPas encore d'évaluation

- Baremo DAT-5 22Document1 pageBaremo DAT-5 22Erika ZáratePas encore d'évaluation

- Pembukuan Ud - TosDocument6 238 pagesPembukuan Ud - TosWahyudi AjjhPas encore d'évaluation

- Appendi Vineland3_App_B-E (1)-26-50Document30 pagesAppendi Vineland3_App_B-E (1)-26-50Buro GroupPas encore d'évaluation

- Bodová StupnicaDocument2 pagesBodová StupnicaGeneral KenobiPas encore d'évaluation

- SBR FDocument8 pagesSBR FJérôme MoiPas encore d'évaluation

- Adobe Scan 03-Feb-2023Document2 pagesAdobe Scan 03-Feb-2023Vineeta TailwalPas encore d'évaluation

- Analisa GambarDocument2 pagesAnalisa GambarSyaifudin LutfiPas encore d'évaluation

- 469 SIP Regional Prodigy 2023 Abacus Question Paper For Foundation Level 1 Below 9 YrsDocument40 pages469 SIP Regional Prodigy 2023 Abacus Question Paper For Foundation Level 1 Below 9 YrsAswini AllePas encore d'évaluation

- Estratégia de Cavalos para Roleta OnlineDocument1 pageEstratégia de Cavalos para Roleta OnlineFrancisco dos Santos PadilhaPas encore d'évaluation

- Scores Amp Percentages Out of 50 Basiccomposition Com PDFDocument2 pagesScores Amp Percentages Out of 50 Basiccomposition Com PDFJOPEARL MAE DELA TORREPas encore d'évaluation

- Evolution 2G 3G PDFDocument94 pagesEvolution 2G 3G PDFAbderrahmen Abderrahmen100% (1)

- Placo 3Document1 pagePlaco 3dersvincePas encore d'évaluation

- Souss-Massa Examen Regional PC 2021 Sujet PDFDocument4 pagesSouss-Massa Examen Regional PC 2021 Sujet PDFAhmed Taha RazinPas encore d'évaluation

- BP 2Document23 pagesBP 2Salem AbkaPas encore d'évaluation

- Iec 60038Document17 pagesIec 60038elyes issaouiPas encore d'évaluation

- Rapport 2émeDocument28 pagesRapport 2émeAdam Ben HamoudaPas encore d'évaluation

- Exercices Dexamens Precedents - Licence s5 TelecommunicationsDocument24 pagesExercices Dexamens Precedents - Licence s5 TelecommunicationsImma StylesPas encore d'évaluation

- BR 132003 FRDocument48 pagesBR 132003 FRsedjalPas encore d'évaluation

- Arrêté Aménagement-Exploitation Dépôts (1968)Document6 pagesArrêté Aménagement-Exploitation Dépôts (1968)Anonh AdikoPas encore d'évaluation

- Le Québec CyclableDocument292 pagesLe Québec CyclableDamselaPas encore d'évaluation

- Commande MPPT Et Contrôle D'un Système PDFDocument6 pagesCommande MPPT Et Contrôle D'un Système PDFspeedov73100% (1)

- PQBE46 S5 PDocument5 pagesPQBE46 S5 PmilevPas encore d'évaluation

- TD 3 Thermodynamique ChimiqueDocument3 pagesTD 3 Thermodynamique Chimiquebabdelmalek202Pas encore d'évaluation

- 8) 30-10-2023-Réunion Sur L'ami de La Step de TamellaletDocument1 page8) 30-10-2023-Réunion Sur L'ami de La Step de TamellaletfdrePas encore d'évaluation

- Accura AntigoDocument46 pagesAccura AntigoLuciandro CunhaPas encore d'évaluation

- Atelier MEF QuestionsDocument10 pagesAtelier MEF QuestionsLau MilPas encore d'évaluation

- Chapitre 1 (Version Sécuricer)Document12 pagesChapitre 1 (Version Sécuricer)rofaidahacini2Pas encore d'évaluation

- Hamdaoui Abdelilah PDFDocument29 pagesHamdaoui Abdelilah PDFzack3443amcPas encore d'évaluation

- Airline ManagerDocument7 pagesAirline ManagerassoPas encore d'évaluation

- Chapitre 5Document19 pagesChapitre 5BodawdSouri100% (1)

- Livrable 3Document11 pagesLivrable 3JossPas encore d'évaluation

- 199 Modele CV LuxembourgDocument2 pages199 Modele CV Luxembourgadegbegilles68Pas encore d'évaluation

- Razafimandrantotl Espa LC 07Document99 pagesRazafimandrantotl Espa LC 07gharsaliihamza3Pas encore d'évaluation

- Print 2023Document46 pagesPrint 2023med.med.1996.mmPas encore d'évaluation

- Cour Eln Diode322Document28 pagesCour Eln Diode322Joujou JuPas encore d'évaluation

- AlgorithmeDocument8 pagesAlgorithmeAbderrahmane OufaqirPas encore d'évaluation

- QCMDocument29 pagesQCMgikkou100% (2)

- Uv VisDocument36 pagesUv Visanon_224403045Pas encore d'évaluation