Académique Documents

Professionnel Documents

Culture Documents

B-2 - Note de Calcul Mécanique Eau Brute 90GAD10BB001002 (GHN 90 M - K11 DC 002 C)

Transféré par

Achraf SametTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

B-2 - Note de Calcul Mécanique Eau Brute 90GAD10BB001002 (GHN 90 M - K11 DC 002 C)

Transféré par

Achraf SametDroits d'auteur :

Formats disponibles

Rservoirs Eau Brute

Note de Calcul Mcanique des Rservoirs Eau Brute 90GAD10BB001/002

Information Client / Projet :

Signataires du Contrat:

POWER Centrales

CENTRALE A CYCLE COMBINE DE GHANNOUCH 1 x 400 MW

Espace rserv aux tampons (Revue et validation du document - si ncessaire) :

Date d'Arrive:

Rfrence

N de Classement STEG:

Historique des Rvisions

Rev. A B Date 08/05/2009 19/06/2009 Auteur BSW BSW Vrifi par MS MS Approuv par IET IET Description / Modification Emis pour Approbation Mise Jour

Description de la Dernire Rvision Mise Jour Echelle Auteur Vrifi Par: BSW MS Type de Document Note de Calcul Titre, S Tit Sous Titre Tit Note de Calcul Mcanique des Rservoirs Eau Brute 90GAD10BB001/002 Numrotation ALSTOM GHN 90 M-------K11 DC 002 C Approuv par IET Statut du Document FA Numro d'identification N d'id tifi ti GHN 90 M-------K11 DC 002 C Rev. Date Lang. C 13/09/2009 Fr./En.

Remplace Responsable Dpt IET Origine du Document

Format A4

Page 1/ 36

Page 1 sur 36

GHN 90 M-------K11 DC 002 C

Rservoirs Eau Brute

SOCIETE TUNISIENNE DE L'ELECTRICITE ET DU GAZ CENTRALE A CYCLE COMBINE DE GHANNOUCH 1 x 400 MW Note de Calcul Mcanique des Rservoirs Eau Brute 90GAD10BB001/002 Ref.: GHN 90 M-------K11 DC 002 C SOMMAIRE (SUMMARY) 1 2 3 3 3 4 8 9 11 12 14 15 21 22 27 PAGE DE GARDE (COVER PAGE) SOMMAIRE (SUMMARY) 1- Objet (Subject) 2- Documents de Rfrence & Standards (Reference Standards & Documents) 3- Paramtres de Conception (Design Parameters) 4- Vrification des Epaisseurs des Viroles (Shell Thickness Check) 5- Vrification Epaisseur Fond (Bottom Thickness Check) 6- Vrification Epaisseur Tle Marginale (Annular Bottom Plate Thickness Check) 7- Vrification Epaisseur Tle Toit (Roof Plate Thickness Check)

Page 2 /

36

8- Vrification Non-Ncessit Poutre Intermdiaire (Intermediate Wind Girder Requirements Check) 9- Vrification Event Central (Check of Central Vent) 10- Analyse Sismique (Seismic Analysis) 11- Analyse de la Stabilit Sous l'Effet du Vent (Stability Check Under Wind Load) 12- Vrification des Ancrages (Anchorage Check) 13- Dimensionnement la Charpente du Toit (Check of Roof Structure)

GHN 90 M-------K11 DC 002 C

Page 2 sur 36

Rservoirs Eau Brute

SOCIETE TUNISIENNE DE L'ELECTRICITE ET DU GAZ CENTRALE A CYCLE COMBINE DE GHANNOUCH 1 x 400 MW Note de Calcul Mcanique des Rservoirs Eau Brute 90GAD10BB001/002 Ref.: GHN 90 M-------K11 DC 002 C

Page 3 /

36

1- OBJET (SUBJECT) L'objectif de ce document est de vrifier les diffrents Elments de deux rservoirs Eau Brute. L'analyse couvrira les diffrents lments du rservoir: Robe, Tle Toit, Tle Bordure/Fond, Raidisseur, Ancrage & Charpente du Toit. The Objective of this documents is to check the different components of two Raw Water Tanks . The analysis covers the differents components of Tanks: Shell, Roof Plate, Bottom & Annular Bottom Plate, Wind Girder, Anchorage and Roof Structure . 2- DOCUMENTS DE REFERENCE & STANDARDS (REFERENCE STANDARDS & DOCUMENTS) 2-1- DOCUMENTS DE REFERENCE (REFERENCE DOCUMENTS) Datasheet des Rservoirs Eau Brute 90GAD10BB001/002 Plan guide rservoir deau brute Plan guide rservoir deau brute Liste des Codes et Norme Equipment Technical Dossier: Miscellaneous Storage Tanks Miscellaneous Storage Tanks Equipment General Technical Requirements Piping Class Manual Spcification Gnrale Peinture 2-2- STANDARDS DE REFERENCE (REFERENCE STANDARDS) API650: Welded Steel Tanks for Oil Storage API RP2000: Venting Atmospheric and Low-Pressure Storage Tanks Nonrefrigerated and Refrigerated AISI T-192: Steel Plate Engineering Data Series - Useful Information - Design of Plate Structures, Volume I & II AISC 360-05: Specification for Structural Steel Buildings 3- PARAMETRES DE CONCEPTION (DESIGN PARAMETERS) Temprature Maximale (Maximum Temperature) Temprature Minimale (Minimum Temperature) Pression Interne (Internal Pressure) Pression Externe (External Pressure) Charge d'Exploitation sur Toit (Live Load on Roof) Vitesse du Vent (Wind Velocity) Acclration Sismique (Seismic Acceleration) Matire Robe (Shell Material) Matire Fond (Bottom Material) Matire Tle Toit (Roof Plate Material) Matire Charpente (Roof Structure Material) 50C -5C NA NA 200kg/m 180km/h 0.1g A283 GR C A283 GR C A283 GR C S235JR GHN/99/M/G02-------/DS/502/A GHN99MG02-------EA005A GHN99MG02-------EA006A GHN00M-------PMFNA131A GHN90M-------K11DL100B GHN90M-------K11ES001B GHN00M--------MEES500A GHN00M--------GS140D GHN00M GS140D GHN00M----------GS120A

GHN 90 M-------K11 DC 002 C

Page 3 sur 36

Rservoirs Eau Brute

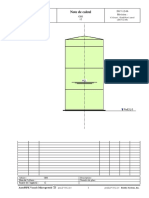

4- Vrification des Epaisseurs des Viroles (Shell Thickness Check)

tsn Hn Hi Zi H2 tsi Zn

Z1

Z2

ts2

ts1

Design Condition Definition 14 <-D: Nominal Tank Diameter (m) 13.5 <-H: Design Liquid Level (m) 1 <-G: Design Specific Gravity 3 <-Cs: Shell Corrosion Allowance (mm) 50 <-Tmax: Maximum Operating Temperature (C) -5 <-Tmin: Minimum Operating Temperature (C) 2.5 <-P: Design Pressure (kPa) Shell Courses Definition 6 <-n: Number of Shell Courses Shell Course Height Zi (m) 2.2 2.2 2.2 2.2 2.2 2.5 2.48 2.48 Nominal Shell Thickness tsi (mm) 10 9 8 8 6 6 8 8 Corro Allow Csi 3 3 3 3 3 3 3 3

No. 1 2 3 4 5 6 7 8 9 10 11 12

H1=Hm

Hm

Material Designation

ASTM A283 GR C [Killled Or Semikilled] ASTM A283 GR C [Killled Or Semikilled] ASTM A283 GR C [Killled Or Semikilled] ASTM A283 GR C [Killled Or Semikilled] ASTM A283 GR C [Killled Or Semikilled] ASTM A283 GR C [Killled Or Semikilled]

ASTM A283 GR C [Killled Or Semikilled] ASTM A283 GR C [Killled Or Semikilled]

GHN 90 M-------K11 DC 002 C

Page 4 sur 36

Rservoirs Eau Brute

Check of 1-Foot Method Applicability D 60m Check of Maximum Design Pressure P 18kPa Allowable Stresses Computation S d = Value From Table 3.2 [If T max <=90C] Sd = 2/3 Y x m [If T max >90C] Minimum Specified yield Strength Y (MPa) 205 205 205 205 205 205 205 205 #N/A #N/A #N/A #N/A Allowable Stress Allowable Stress for the Yield Strength for the design Hydrostatic Test Reduction Factor Condition Condition m Sd (MPa) St (MPa) NA NA NA NA NA NA NA NA #N/A #N/A #N/A #N/A 136.67 136.67 136.67 136.67 136.67 136.67 136.67 136.67 #N/A #N/A #N/A #N/A 154 154 154 154 154 154 154 154 #N/A #N/A #N/A #N/A OK OK OK

No.

1 2 3 4 5 6 7 8 9 10 11 12 Tmax 260C

Minimum Shell Thickness Computation 13.76 <-Hm: Modified Liquid Level (m)

Hm = H +

H i = Hm Z k

k =1 i

P 9.8G

tdi =

4.9 D ( H i 0.3) G

tti =

S di 4.9 D ( H i 0.3)

+ Csi

Sti

Design Shell Thickness tdi (mm) 9.75 8.65 7.55 6.44 5.34 4.23 0.00 0.00 0.00 0.00 0.00 0.00

5 6 tei = 8 10

if D < 15m if 15m D < 36m if 36m D < 60m if D 60m

Minimum Shell Thickness tsmi (mm) 9.75 8.65 7.55 6.44 5.34 5.00 0.00 0.00 0.00 0.00 0.00 0.00

No. 1 2 3 4 5 6 7 8 9 10 11 12

Shell Course Height Hi (m) 13.76 11.56 9.36 7.16 4.96 2.76 0.26 -2.22 -4.70 -4.70 -4.70 -4.70

Erection Shell Thickness tei (mm) 5 5 5 5 5 5 5 5 5 5 5 5

Hydrostatic Shell Thickness tti (mm) 5.99 5.01 4.03 3.05 2.07 1.09 0.00 0.00 0.00 0.00 0.00 0.00

GHN 90 M-------K11 DC 002 C

Page 5 sur 36

Rservoirs Eau Brute

tsi tsmi Allowable Maximum Shell Thickness Maximum Allowable Shell Thickness tmai (mm) 25.00 25.00 25.00 25.00 25.00 25.00 25.00 25.00 #N/A #N/A #N/A #N/A Nominal Shell Thickness tsi (mm) 10.00 9.00 8.00 8.00 6.00 6.00 8.00 8.00 0.00 0.00 0.00 0.00

OK

No. 1 2 3 4 5 6 7 8 9 10 11 12

Status OK OK OK OK OK OK OK OK #N/A #N/A #N/A #N/A

Impact Test Requirement Minimum Allowable Temperature without Impact Test Tai (C) -8.92 -9.69 -10.46 -10.46 -12.00 -12.00 -10.46 -10.46 #N/A #N/A #N/A #N/A Status (No Impact Test is required) OK OK OK OK OK OK OK OK #N/A #N/A #N/A #N/A

No. No 1 2 3 4 5 6 7 8 9 10 11 12

Material Group I I I I I I I I #N/A #N/A #N/A #N/A

GHN 90 M-------K11 DC 002 C

Page 6 sur 36

Rservoirs Eau Brute

Shell Weight Computation Shell Course Height Zi (m) 2.20 2.20 2.20 2.20 2.20 2.50 0.00 0.00 0.00 0.00 0.00 0.00 Nominal Shell Thickness tsi (mm) 10.00 9.00 8.00 8.00 6.00 6.00 0.00 0.00 0.00 0.00 0.00 0.00 Course Weight Wi (kg) 7595.74 6836.17 6076.59 6076.59 4557.45 5178.92 0.00 0.00 0.00 0.00 0.00 0.00 Corroded Course Weight Wci (kg) 5317.02 4557.45 3797.87 3797.87 2278.72 2589.46 0.00 0.00 0.00 0.00 0.00 0.00

No. 1 2 3 4 5 6 7 8 9 10 11 12

36 321.46 <-Ws: Non Corroded Shell Weight (kg) 22 338.39 <-Wsc: Corroded Shell Weight (kg)

GHN 90 M-------K11 DC 002 C

Page 7 sur 36

Rservoirs Eau Brute

5- Vrification Epaisseur Fond (Bottom Thickness Check) Input Parameters

ASTM A283 GR C [Semikilled] Singlewelded Full Fillet Lap Joint

<-Bottom Plate Material Designation

<-Bottom Plate Joint

Single-welded Butt Joint

Single-welded Butt Joint with Backing Strip Single-welded Full Fillet Lap Joint

tb

Z tb

Square or V Grooves

Square or V Grooves

tb

5 tb

50

Z5

min(25;5*tb)

14 3 9 -5 600

<-D: Nominal Tank Diameter (m) <-Cb: Bottom Plate Corrosion Allowance (mm) <-tb: Nominal Bottom Plate Thickness (mm) <-Tmin: Minimum Operating Temperature (C) <-rab: Distance inside shell and any lap-welded joint in the bottom (mm)

Bottom Plate Thickness Check 9 <-tbmin: Minimum Required Bottom Plate Thickness (mm) t bmin =6mm+C b tb tbmin Impact Test Requirement I <-Material Group -9.69 <-Ta: Minimum Allowable Temperature without Impact Test (C) Tmin Ta (No Impact Test is required) Bottom Plate Weight Computation 9 091.22 <-Wb: Non Corroded Bottom Plate Weight (kg) 6 060.81 <-Wbc: Corroded Bottom Plate Weight (kg) OK OK

GHN 90 M-------K11 DC 002 C

tb

Page 8 sur 36

Rservoirs Eau Brute

6- Vrification Epaisseur Tle Marginale (Annular Bottom Plate Thickness Check)

pab ts1

Input Parameters

ASTM A283 GR C [Semikilled] ASTM A283 GR C [Semikilled]

rab

50

<-Annular Bottom Plate Material Designation <-Shell Plate Material Designation <-ts1: First Shell Course Thickness (mm) <-D: Nominal Tank Diameter (m) <-H: Design Liquid Level (m) <-G: Design Specific Gravity (m) <-Cab: Annular Bottom Plate Corrosion Allowance (mm) <-tab: Nominal Annular Bottom Plate Thickness (mm) <-rab: Distance inside shell and any lap-welded joint in the bottom (mm) <-pab: Outside projection outside the shell (mm) <-Tmin: Minimum Operating Temperature (C)

10 14 13.5 1 3 9 600 60 -5

Check of Annular Bottom Plate Thickness 90.55 <-h: Hydrostatic Test Stress in the First Shell Course (MPa)

h =

4.9 D ( H 0.3) t s1

OK

9 <-tabmin: Minimum Required Annular Bottom Plate Thickness (mm) tab tabmin Check of Annular Bottom Plate Inside Projection 600.00 <-rabmin: Minimum Distance inside shell and any lap-welded joint in the bottom (mm)

215tab rab min = Max 600mm; 0.5 ( HG )

50 <-pabmin: Minimum Outside projection outside the shell (mm) rab rabmin pab pabmin OK OK

GHN 90 M-------K11 DC 002 C

Page 9 sur 36

Rservoirs Eau Brute

Impact Test Requirement I <-Material Group -9.69 <-Ta: Minimum Allowable Temperature without Impact Test (C) Tmin Ta (No Impact Test is required) Annular Bottom Plate Weight Computation 2 144.60 <-Wab: Non Corroded Annular Bottom Plate Weight (kg) 1 429.74 <-Wabc: Corroded Annular Bottom Plate Weight (kg) OK

GHN 90 M-------K11 DC 002 C

Page 10 sur 36

Rservoirs Eau Brute

7- Vrification Epaisseur Tle Toit (Roof Plate Thickness Check)

Input Parameters

ASTM A283 GR C [Semikilled]

<-Roof Plate Material Designation <-D: Nominal Tank Diameter (m) <-: Angle of the cone elements to the horizontal (Deg) <-tr: Nominal Roof Plate Thickness (mm) <-Cr: Roof Plate Corrosion Allowance (mm)

14 9.46 5 0

Roof Plate Thickness Check 5 <-trmin: Minimum Required Roof Plate Thickness (mm) t rmin =5mm+C r tr trmin Roof Plate Weight Computation 6 125.41 <-Wr: Non Corroded Roof Plate Weight (kg) 6 125.41 <-Wrc: Corroded Roof Plate Weight (kg) OK

GHN 90 M-------K11 DC 002 C

Page 11 sur 36

Rservoirs Eau Brute

8- Vrification Non-Ncessit Poutre Intermdiaire (Intermediate Wind Girder Requirements Check)

Design Condition Definition

ASTM A283 GR C [Semikilled]

<-Top Shell Course Material Designation

14 <-D: Nominal Tank Diameter (m) 180 <-V: Wind Velocity (km/h) 50 <-Tmax: Maximum Operating Temperature (C) Shell Courses Definition 6 <-n: Number of Shell Courses Shell Course Height Zi (m) 2.2 2.2 2.2 2.2 2.2 2.5 Nominal Shell Thickness tsi (mm) 10 9 8 8 6 6

No. 1 2 3 4 5 6 7 8 9 10 11 12

Maximum Design Temperature Factor Computation 205 <-Y: Minimum Specified yield Strength (MPa) NA <-m: Yield Strength Reduction Factor 205 <-YT: Specified yield Strength at maximum Design Temperature (MPa) 1 <-k: Intermediate Wind Girder Reduction Factor at maximum Design Temperature Maximum Height of unstiffened Shell Computation 6 <-tsn: As ordered thickness of the top shell course (mm) 0.79 <-: Wind Modification Factor

= V

12.60 <-H1: Vertical Distance between intermediate wind girder and the top angle of the shell or the top wind girder of an open-top tank (m)

3

160

t H1 = 9.47t sn sn k D

GHN 90 M-------K11 DC 002 C

Page 12 sur 36

Rservoirs Eau Brute

Maximum Height of unstiffened Shell Computation

t Wtri = Z i sn t si

No. 1 2 3 4 5 6 7 8 9 10 11 12 Shell Course Height Zi (m) 2.2 2.2 2.2 2.2 2.2 2.5 0 0 0 0 0 0

Nominal Shell Thickness tsi (mm) 10 9 8 8 6 6 0 0 0 0 0 0

Transposed width of Each Shell Course Wtri (mm) 0.61 0.80 1.07 1.07 2.20 2.50 0.00 0.00 0.00 0.00 0.00 0.00

8.26 <-Wtr: Height of the transformed shell (m)

Wtr = Wtri

i =1

12.60 <-H1: Vertical Distance between intermediate wind girder and the top angle of the shell or the top wind girder of an open-top tank (m) Wtr < H1 OK

GHN 90 M-------K11 DC 002 C

Page 13 sur 36

Rservoirs Eau Brute

9- Vrification Event Central (Check of Central Vent)

di Z6

6

150

SS316 MESH 0.5MM

Z5

Input

Flash Point 37.8C

<-Flash Point <-Qin: Liquid Inlet Flow Rate (m3/h) <-Qout: Liquid Outlet Flow Rate (m3/h) <-V: Tank Capacity (m3) <-Pi: Maximum Inlet Pressure (kPa) <-Pe: Maximum Vacuum Pressure (kPa) <-K: Head Loss Coefficient <-: Air Density (kg/m3) <-di: Vent Pipe Internal Diameter (mm)

200 200 2 000 2.5 0.25 2.5 1.2 154.08

In/Out Breathing Resulting from maximum Out/In flow of liquid from the tank 188.000 <-Qain: Air Inbreath Flow Rate (m3/h) 188.000 <-Qaout: Air Outbreath Flow Rate (m3/h)

In/Out Breathing Resulting From Thermal Effect 337.000 <-Qainth: Air Inbreath Flow Rate (m3/h) 202.000 <-Qaoutth: Air Outbreath Flow Rate (m3/h) 10 V 30 000m3 Maximum Out/In flow of liquid from the tank 525.000 <-Qe: Maximum Inbreath Flow Rate (m3/h) 390.000 <-Qi: Maximum Outbreath Flow Rate (m3/h) 0.011 <-A: Minimum Venting Area (m) OK

KQ 2 KQ 2 i e A = Max ; 2 Pe 2 Pi

0.019 <-An: Nominal Venting Area (m) An A OK

GHN 90 M-------K11 DC 002 C

Page 14 sur 36

Rservoirs Eau Brute

10- Analyse Sismique (Seismic Analysis) Mechanically Anchored Tank

Geometric Parameters 14 <-D: Nominal Tank Diameter (m) 13.5 <-H: Maximum Design Product Level (m) 7.66666667 <-tu: Equivalent Uniform Thickness of Tank Shell (mm) 5.97705314 <-Xs: Height from Bottom of the Tank Shell to Shell Center of Gravity (m) 14.0833333 <-Xr: Height from Bottom of the Tank Shell to Roof Center of Gravity (m) 6 <-ta: Corroded Thickness of the Annular Bottom Plate (mm) 60 <-ra: Annular Bottom Plate Outside Projection (mm) 0.7 <-Hfh: Net Free Height Between Maximum Liquid Level & Shell Top Angle (m) Shell Plate Parameters 6 <-n: Number of Shell Courses No. 1 2 3 4 5 6 7 8 9 10 11 12 Zk (mm)

2500 2500 2500 2500 2000 1500

tsk (mm)

10 9 8 6 6 6

Ck (mm)

3 3 3 3 3 3

Sk (MPa)

137 137 137 137 137 137

Ftyk (MPa)

205 205 205 205 205 205

<-Zk: Shell Course Height (mm) <-tsk: Nominal Shell Thickness (mm) <-Csk: Shell Course Corrosion Allowance (mm) <-Sk: Allowable Stress for the design Condition (MPa) <-Ftyk: Mnimum Specified Yield Strength of Shell Course (MPa) Seismic Parameters

Self-Anchored

<-Type of Anchorage (Self-Anchored;Mechanically-Anchored)

0.1 <-SP: Design Level Peak Ground Acceleration (%g) 1.25 <-I: Seismic Importance Factor (Table E-5) Class E <-Site Class (Class A/B/C/D/E) Weight & Material Propperties Definition 110 223 <-Wf: Weight of Tank Bottom (N) 21 141 850 <-Wp: Total Weight of Tank Content (N) 73 605 <-Wr: Total Weight of Tank Roof (Plate, Structure, Roof Nozzle & Handrail) (N) 377 425 <-Ws: Total Weight of Tank Shell & Appurtenances (Shell, Ladder, Shell Nozzle & Platform) (N) 2.5 <P: Internal Design Pressure (kPa) 1 <G: Design Specific Gravity 1 000 <-: Density of Fluid (kg/m3) 200 000 <-E: Elastic Modulus of Tank Material (MPa) 205 <-Fy: Minimum Specified Yield Strength of Annular Bottom Plate (MPa)

GHN 90 M-------K11 DC 002 C

Page 15 sur 36

Rservoirs Eau Brute

Impulsive Natural Period Computation 0.96 <-H/D: Maximum Design Liquid Level To Nominal Tank Diameter Ratio 6.15 <-Ci: Coefficient for Determining Impulsive Period of Tank System (Fig. E-1) 0.223 <-Ti: Natural Period of Vibration for Impulsive mode of Behavior (s)

Ti =

1 Ci H 2000 tu D

Convective Period Computation 0.58 <-Ks: Sloshing Period Coefficient

Ks =

0.578 3.68H tanh D

3.90 <-Tc: Natural Period of the Convective (Sloshing) Mode of Behaviour of the Liquid (s)

Tc = 1.8K s D

Impulsive Spectral Acceleration Coefficients Computation 0.25 <-SS: Mapped Earthquake Spectral Response Acceleration Parameter at 0.2s (%g)

S S = 2.5S P

2.5 3.5 0.67 0.15 <-Fa: Acceleration-based Site Coefficient (at 0.2s Period) (Table E-1) <-Rwi: Force Reduction Coefficient for the Impulsive Mode (Table E-4) R E 4) <-Q: Scaling Factor <-Ai: Impulsive Design Response Spectrum Acceleration Coefficient (%g)

I I Ai = Max 0.007; 2.5QFa S P If Class E 0.5S1 Rwi Rwi

Convective Spectral Acceleration Coefficients Computation 0.125 <-S1: Mapped Earthquake Spectral Response Acceleration Parameter at 1s (%g)

S1 = 1.25S P

3.425 2 4 0.685 <-Fv: Velocity-based Site Coefficient (at 1s Period) (Table E-2) <-Rwc: Force Reduction Coefficient for the Convective Mode (Table E-4) <-TL: Regional-dependent Transition Period for longer period Ground Motion (s) <-TS: Time Coefficient

TS =

Fv S1 Fa S S

1.5 <-K: Coefficient to Adjust the Spectral Acceleration for 5% to 0.5% 0.07 <-Ac: Convective Design Response Spectrum Acceleration Coefficient (%g)

TS I 2.5KQFa S P T R if Tc TL c wc Ac = Ai 2.5KQF S TS TL I if T > T a P c L Tc2 Rwc

GHN 90 M-------K11 DC 002 C

Page 16 sur 36

Rservoirs Eau Brute

Design Loads Computation 16 362 226 <-Wi: Effective Impulsive Portion of the Liquid Weight (N)

5 034 222 <-Wc: Effective Convective (Sloshing) Portion of the Liquid Weight (N)

D tanh 0.866 H W if D 1.333 p D H 0.866 Wi = H D D 1 0.218 H W p if H < 1.333

Wc = 0.230 D 3.67 H tanh H D Wp

2 518 375 <-Vi: Design Base Shear due to Impulsive Component (N)

Vi = Ai (Ws + Wr + W f + Wi )

345 748 <-Vc: Design Base Shear due to Convective Component (N)

Vc = AcWc

2 541 998 <-V: Total Design Base Shear (N)

V = Ai2 + Ac2

Center of Action Computation (For Ring Wall Overturning Moment) 5.434 <-Xi: Height From Bottom of Tank Shell to the Center of Action of Lateral Impulsive Force (m)

D 0.375H if H 1.333 Xi = 0.5 0.094 D H if D < 1.333 H H

9.901 <-Xc: Height From Bottom of Tank Shell to the Center of Action of Lateral Convective Force (m)

3.67 H cosh 1 D X c = 1 3.67 H sinh 3.67 H D D

Center of Action Computation (For Slab Overturning Moment) 7.590 <-Xis: Height From Bottom of Tank Shell to the Center of Action of Lateral Impulsive Force (m)

D 0.866 D H 0.375 1 + 1.333 1 H if 1.333 H tanh 0.866 D X is = H D D < 1.333 0.5 + 0.06 H if H H

10.108 <-Xcs: Height From Bottom of Tank Shell to the Center of Action of Lateral Convective Force (m)

3.67 H cosh D 1.937 H X cs = 1 3.67 H 3.67 H sinh D D

GHN 90 M-------K11 DC 002 C

Page 17 sur 36

Rservoirs Eau Brute

Overturning Moment Computation 14 141 514 <-Mrw: Ringwall Moment (Nm)

M rw = Ai (Wi X i + Ws X s + Wr X r ) + Ac (Wc X c )

2

19 289 761 <-Ms: Slab Moment (Nm)

M s = Ai (Wi X is + Ws X s + Wr X r ) + Ac (Wc X cs )

2

Vertical Seismic Acceleration Computation 0.058 <-Av: Vertical Seismic Acceleration Coefficient (%g)

Av = 0.35QFa S P

10 524 <-Fv: Vertical Seismic Up/Down Load (N)

Fv = 0.4 Av (Ws + Wr )

Dynamic Liquid Hoop Stresses Computation

2 Yk D D Yk Yk = H Z j 1.333 8.48 AGDH 0.5 tanh 0.866 if i H H j =1 H H 2 Yk Yk D 2 tk = t sk Ck N ik = 5.22 AGD 0.5 i if H < 1.33 & Yk < 0.75D 0.75D 0.75D N hk = 4.9GYk D 2.6 Ai GD 2 if D < 1.33 & Yk 0.75D H 2 3.68 ( H Yk ) 2 2 N hk + N ik + N ck + ( Av N hk ) 1.85 AcGD 2 cosh Tk = D tk N ck = 3.68H cosh STk = 1.33Sk D

k 1

No. 1 2 3 4 5 6 7 8 9 10 11 12

Yk (m)

13.5 11 8.5 6 3.5 1.5

tk (mm)

7 6 5 3 3 3

Nik Nck Nhk (N/mm) (N/mm) (N/mm)

75.83 75.83 73.36 62.14 42.29 20.20 1.43 1.75 2.86 5.24 9.97 16.81 926.10 754.60 583.10 411.60 240.10 102.90

Tk (MPa)

145.60 140.38 132.80 159.48 95.25 43.28

Check STk (MPa) TkSTk

182.21 182.21 182.21 182.21 182.21 182.21 OK OK OK OK OK OK

<-Yk: Distance From Liquid Surface to Shell Course Bottom (m) <-tk: Corroded Shell Thickness (mm) <-Nik: Impulsive Hoop Membrane Force in Tank Shell (N/mm) <-Nck: Convective Hoop Membrane Force in Tank Shell (N/mm) <-Nhk: Product Hydrostatic Membrane Force (N/mm) <-Tk: Total Combined Hoop Stress in the Shell (MPa) < S : Allowable Tensile Stress For Seismic Load Case (MPa)

GHN 90 M-------K11 DC 002 C

Page 18 sur 36

Rservoirs Eau Brute

Anchorage Requirement Check 0.977 <-Ge: Effective Specific Gravity Including Vertical Seismic Effects

Ge = G (1 0.4 Av )

30 882 <-wa: Force Resisting Uplift in Annular Region (N/m)

wa = Min 99ta Fy HGe ; 201.1HDGe

1 674 <-wrs: Roof Loading Acting on Shell (N/m)

wrs =

Wr D

10 255 <-wt: Shell & Roof Weight Acting at Base of Shell (N/m)

wt =

Ws + Wrs D PD 4

8 750 <-wint: Design uplift Load due to Product Pressure (N/m)

wint =

1.93 <-J: Anchorage Ratio

J=

J > 1.54

M rw D ( wt (1 0.4 Av ) + wa 0.4wint )

2

OK

Anchor Load Computation 81 832 <-wAB: Design uplift Load On Anchors per Unit Circumferential Length (N/m)

1.273M rw wAB = wt (1 0.4 Av ) 2 D

3 599 166 <-US: Seismic Uplift Load (N)

U S = DwAB

Shell Compression Stresses Computation 15 <-c: Maximum Longitudinal Shell Compression Stress (MPa)

c = wt (1 + 0.4 Av ) +

1.273M rw D

1 1000t1

42 <-Fc: Allowable Longitudinal Shell-Membrane Compression Stress (MPa)

t1 GHD 2 83 if 44 t12 D Fc = 2 Min 83 t1 + 7.5 GH ; 0.5 F if GHD < 44 ty1 2.5 D t12

c Fc OK

GHN 90 M-------K11 DC 002 C

Page 19 sur 36

Rservoirs Eau Brute

Tank Freeboard Check 0.137 <-Af: Acceleration Coefficient for Sloshing Wave Height Calculation (%g)

Ts 2.5KQFa S P I if Tc 4 Tc Af = 4T 2.5KQFa S P I 2s if Tc > 4 Tc

0.962 <-s: Height of Sloshing Wave Above the Product (m)

s = 0.5 DAf

0.673 <-Hf: Minimum Free Height (m)

H f = 0.7 s

Hf Hfh OK

Seismic Loading Computation 0.15 <-Ai: Impulsive Design Response Spectrum Acceleration Coefficient (%g) 0.058 <-Av: Vertical Seismic Acceleration Coefficient (%g) 10 524 <-Fv: Vertical Seismic Up/Down Load (N) 2 541 998 <-V: Total Design Base Shear (N) 14 141 514 <-Mrw: Ringwall Moment (Nm) 146 <-T1: First Shell Course Hoop Stress due To Seismic Loading & Product Weight (MPa) 3 599 166 <-US: Ring Wall Uplift Load due to Seismic & Dead Load (N)

GHN 90 M-------K11 DC 002 C

Page 20 sur 36

Rservoirs Eau Brute

11- Analyse de la Stabilit Sous l'Effet du Vent (Stability Check Under Wind Load) Anchored Tank

Geometric Parameters 14 <-D: Nominal Tank Diameter (m) 13.5 <-H: Maximum Design Product Level (m) 6 <-ta: Corroded Thickness of the Annular Bottom Plate (mm) 7 <-t1: Corroded Thickness of First Shell Course (mm) Weight & Material Propperties Definition 73 605 <-Wr: Total Weight of Tank Roof (Plate, Structure, Roof Nozzle & Handrail) (N) 377 425 <-Ws: Total Weight of Tank Shell & Appurtenances (Shell, Ladder, Shell Nozzle & Platform) (N) 577 882 <-WT: Total Weight of Tank (N) 1 <G: Design Specific Gravity 180 <-V: Design Wind Speed (m/s) Wind Overturning Moment Computation 0.77 <-PC: Wind Pressure on Vertical Projected Areas of Cylindrical Surface (kPa)

V PC = 0.86 190

1.29 <-PU: Wind Pressure Uplift on Roof Surface (kPa)

V P = 1.44 U 190

1 021 165 <-Mw: Wind Overturning Moment About Shell-to-Bottom Joint (Nm)

Mw =

HD 2 PC D 3 P U + 2 8

Wind Loading on Foundation 1.29 <-PU: Wind Pressure Uplift on Roof Surface (kPa) 1 021 165 <-Mw: Wind Overturning Moment About Shell-to-Bottom Joint (Nm) 795 804 <-Fvw: Wind Upward Vertical Loading (N) 145 881 <-Vw: Wind Horizontal Loading (N)

GHN 90 M-------K11 DC 002 C

Page 21 sur 36

Rservoirs Eau Brute

12- Vrification des Ancrages (Anchorage Check) Mechanically Anchored Tank

t1 e c w

dh

k ta ra db

g f

Anchorage Parameters S275JR <-Anchor Bolt Material 265 <-Sya: Anchor Bolt Material Yield Strength (MPa) <S 206 <-Sy: First Shell Course Material Yield Strength (MPa) 1.5 <-Ca: Anchor Chair Corrosion Allowance (MPa) 13.5 <H: Design Liquid Level (m) 14 <-D: Nominal Tank Diameter (m) M30 <-Anchor Bolt Diameter 36 <-nA: Number of Equally-Spaced Anchors Around Tank Circumference 220 <-a: Top Plate Width (mm) 150 <-b: Top Plate Length (mm) 30 <-c: Top Plate Thickness (mm) 80 <-e: Anchor Bolt Eccentricity (mm) 120 <-g: Distance Between Vertical Plate (mm) 500 <-h: Chair Height (mm) 25 <-j: Vertical Plate Thickness (mm) 10 <-w: Weld Size (Leg Dimension) (mm) 6 <-ta: Corroded Thickness of the Annular Bottom Plate (mm) 60 <-ra: Annular Bottom Plate Outside Projection (mm) 7 <-t1: First Shell Course Corroded Thickness (mm) 5 <-th: Roof Plate Thickness (mm) 42 <-dh: Bolt Hole Diameter (mm) Seismic Load Parameters 10 524 <-Fv: Vertical Seismic Up/Down Load (N) 2 541 998 <-V: Total Design Base Shear (N) 14 141 514 <-Mrw: Ringwall Moment (Nm) 146 <-T1: First Shell Course Hoop Stress due To Seismic Loading & Product Weight (MPa) 3 599 166 <-US: Ring Wall Uplift Load due to Seismic & Dead Load (N) Wind Load Parameters 1 021 165 <-Mw: Wind Overturning Moment About Shell-to-Bottom Joint (Nm) M Shell to Bottom 795 804 <-Fvw: Wind Upward Vertical Loading (N) 145 881 <-Vw: Wind Horizontal Loading (N)

GHN 90 M-------K11 DC 002 C

Page 22 sur 36

Rservoirs Eau Brute

Design Parameters 1.5 <P: Internal Design Pressure (kPa) 1 <G: Design Specific Gravity <Frangible Joint Design (Yes/No) No 0 <Pf: Failure Pressure (0 if None Frangible Joint Design) (kPa) 0 <Pt: Internal Test Pressure (kPa) 252 589 <-W1: Corroded Dead Load of Shell & Roof Excluding Roof Plate Weight (N) 313 857 <-W2: Corroded Dead Load of Shell & Roof (N) 389 763 <-W3: Dead Load of Shell & Roof Excluding Roof Plate Weight (N) Bolt Parameters Computation 30 <-db: Nominal Bolt Diameter (mm) 519 <-As: Bolt Nominal Stress Area (mm) db 25mm D/nA 3m Anchor Bolt Check OK OK

PABi =

No.

Ui nA

PAi = Min ( S ya As ;1.5 PABi )

Load Case

ABi =

PAi As

Ui (N) 0 0 0 0 0 PABi (N) 0 0 0 0 0 103 516 5 375 109 505 PAi (N) 0 0 0 0 0 137 535 8 063 137 535 ABi (MPa) 0 0 0 0 0 199 10 211

SABi (MPa) Formula Value Check ABi SABi OK OK OK OK OK OK OK OK

Net Uplift Formula U (N) (P-0.08th)D-W1 )D -W (Pt-0.08th)D-W1 (1.5Pf-0.08th)D-W3 (3Pf-0.08th)D-W3 4Mw/D-W2 4Mrw/D-W2 (P-0.08th)D+ 4Mw/D-W1 (P-0.08th)D+ 4Mrw/D-W1

1 2 3 4 5 6 7 8

Dead Weight & Internal Design Pressure P Dead Weight & Test Pressure

105 140 Sya Sya 0.8 Sya 0.8 Sya 140 0.8 Sya

105 140 265 265 212 212 140 212

Failure Pressure

Frangible Pressure

Dead Weight & Wind Load

Dead Weight & Seismic Load Design Pressure, Dead Weight & Wind Load Design Pressure, Dead Weight & Seismic Load

3 726 576 193 505 3 942 176

<-Ui: Net Uplift (0 if Negative Value) (N) <-PABi: Anchor Design Load (N) <-PAi: Anchorage Attachment Design Load (N) <-ABi: Anchor Bolt Tensile Stress (MPa) <-ABi: Anchor Bolt Tensile Stress (MPa) <-SABi: Allowable Anchor Bolt Stress (MPa)

GHN 90 M-------K11 DC 002 C

Page 23 sur 36

Rservoirs Eau Brute

Anchor Chair Parameters Computation 28.5 <-cc: Corroded Thickness of Anchor Chair Top Plate (mm)

cc = c Ca

23.5 <-jc: Vertical Plate Corroded Thickness (mm)

jc = j Ca

49 <-f: Distance from Outside of Top Plate to Edge of Hole (mm)

f = be b + ra 2 D 2

dh 2

105 <-k: Average Vertical Plate width (mm)

k=

7000 <-R: Shell Internal Radius (mm)

R=

0.970 <-Z: Reduction Factor

Z=

1 0.177ata 25.4 Rt1 ta +1 t1

2

Anchor Chair Top Plate Check

Stbi =

PAi ( 0.375 g 0.22db ) fcc2

SSi (MPa) Net Uplift Formula U (N) (P-0.08th)D-W1 (Pt-0.08th)D-W1 (1.5Pf-0.08th)D-W3 (3Pf-0.08th)D-W3 4Mw/D-W2 4Mrw/D-W2 (P-0.08th)D+ 4Mw/D-W1 (P-0.08th)D+ 4Mrw/D-W1 Stbi (MPa) 0 0 0 0 0 133 8 133 Check Stbi Ssi OK OK OK OK OK OK OK OK

No.

Load Case Dead Weight & Internal Design Pressure Dead Weight & Test Pressure

Formula

Value

1 2 3 4 5 6 7 8

140 170 Sy Sy 170 170 170 170

140 170 206 206 170 170 170 170

Failure Pressure

Frangible Pressure

Dead Weight & Wind Load

Dead Weight & Seismic Load Design Pressure, Dead Weight & Wind Load Design Pressure, Dead Weight & Seismic Load

<-Stbi: Anchor Chair Top Plate Bending Stress (MPa) <-SSi: Allowable Anchor Chair & Shell Stress (MPa)

GHN 90 M-------K11 DC 002 C

Page 24 sur 36

Rservoirs Eau Brute

Shell Stresses Check

P e 1.32Z 0.031 Sbi = Ai + t12 1.43ah + 4ah 0.333 Rt1 ( ) Rt1

Si = S1i S2i

S1i = S2i

S1i (MPa) 135 132 132 132 132 165 135 165 S2i (MPa) 0 0 0 0 0 142 9 145

i =

PAi 2 w ( a + 2h )

Sbi (MPa) 0 0 0 0 0 162 9 162

Smax i = Max ( S1i ; S2i ; Si )

Hoop Stress Formula h (MPa) PD/t1+4.9GHD/t1 PtD/t1+4.9HD/t1 hi (MPa) 135 132 132 132 132 146 135 149 i (MPa) 0.00 0.00 0.00 0.00 0.00 7.97 0.47 7.97

{ 1 = { 2

135 132 132 132 132 23 126 21

1 bi + hi + 2

bi

( bi hi ) ( bi hi

SSi (MPa) 140 170 206 206 170 170 170 170

+ hi

Smaxi (MPa) 135 132 132 132 132 165 135 165

} ) + 4 }

2

+ 4 i2

2 i

No.

Si (MPa)

Check Smaxi Ssi OK OK OK OK OK OK OK OK

1 2 3 4 5 6 7 8

1.5PfD/t1+4.9GHD/t1 3PfD/t1+4.9GHD/t1 4.9GHD/t1 T1 PD/t1+4.9GHD/t1 PD/t1+T1

<-Sbi: Shell Bending Stress at Anchor Chair Junction (MPa) <-Shi: Hoop Stress at Anchor Chair Junction (MPa) <-i: Shear Stress at Anchor Chair Junction (MPa) <-S1i: First Principal Stress at Anchor Chair Junction (MPa) <-S2i: Second Principal Stress at Anchor Chair Junction (MPa) <-Si: Tresca Combined Stress at Anchor Chair Junction (MPa) <-Smaxi: Tresca Combined Stress at Anchor Chair Junction (MPa) <-SSi: Allowable Anchor Chair & Shell Stress (MPa) Vertical Side Plate Check 137 535 <-PAmi: Anchorage Attachment Maximum Design Load (N) 20 <-jmin: Minimum Vertical Plate Thickness (mm)

1 PAmi ;12.7 mm; 0.04 [ h c ] + Ca jmin = Max k 170 MPa

j jmin OK

GHN 90 M-------K11 DC 002 C

Page 25 sur 36

Rservoirs Eau Brute

Weld Check

vi =

PAi 2 w ( a + 2h )

hi =

PAi e 2 w ( ah + 0.667h )

2 2 Ti = vi + hi

No.

vi (MPa) 0.00 0.00 0.00 0.00 0.00 7.97 0.47 7.97

hi (MPa) 0.00 0.00 0.00 0.00 0.00 2.81 0.16 2.81

Ti (MPa) 0.00 0.00 0.00 0.00 0.00 8.45 0.50 8.45

SSi (MPa) 140 170 206 206 170 170 170 170

Check Smaxi Ssi OK OK OK OK OK OK OK OK

1 2 3 4 5 6 7 8

<-vi: Weld Vertical Stress (MPa) <-hi: Weld Horizontal Stress (MPa) <-i: Weld Total Stress (MPa) <-SSi: Allowable Anchor Chair & Shell Stress (MPa)

GHN 90 M-------K11 DC 002 C

Page 26 sur 36

Rservoirs Eau Brute

13- Dimensionnement la Charpente du Toit (Check of Roof Structure)

Dc

Main Geometric Parameters 14000 <-D: Nominal Tank Diameter (mm) 9.46 <-: Slope Angle (Deg) Compression Ring Parameters

tcr

tcr tcr

1400 10 140 S235JR 200 000 235

<-Dc: Compression Ring Outside Diameter (mm) <-tcr: Compression Ring Box Plate Thickness (mm) <-a: Compression Ring Box Width (mm) <-Compression Ring Material Designation <-Ecr: Compression Ring Material Young Modulus (MPa) <-Ycr: Compression Ring Minimum Yield Strength (MPa)

GHN 90 M-------K11 DC 002 C

b=Dr/cos()

Dr

Page 27 sur 36

Rservoirs Eau Brute

Shell Compression Ring Definition 5 <-tr: Nominal Roof Plate Thickness (mm) 0 <-Cr: Roof Plate Corrosion Allowance (mm) 6 <-ts: Nominal Shell Plate Thickness (mm) 3 <-Cs: Shell Plate Corrosion Allowance (mm) 20 <-r: Roof Plate Position (mm) L130x12 <-Shell Compression Ring Section S275JR <-Shell Compression Ring Material Designation 200 000 <-Eco: ShellCompression Ring Material Young Modulus (MPa) 235 <-Yco: Shell Compression Ring Minimum Yield Strength (MPa) Loadings Definition 45 <-DLs: Self Weight of Roof Structure (kg/m) 45 <-DL: Roof Plate Roof Accessories Weight (kg/m) 200 <-LL: Live Load on Roof (kg/m) 1.292 <-PU: Wind Pressure Uplift on Roof Surface (kPa) 0.058 <-Av: Vertical Seismic Acceleration Coefficient (%g) 2.5 <-Pi: Design Internal Pressure (kPa) 0.25 <-Pe: Design External Pressure (kPa) 0 <-Pt: Hydrostatic Test Pressure (kPa) Rafter Definition IPE180 <-Rafter Section 28 <-N: Total Number of Roof Rafter S235JR <-Rafter Material Designation 200 000 <-E: Rafter Material Young Modulus (MPa) 235 <-Y: Rafter Minimum Yield Strength (MPa) Main Rafter Characteristics 2 395 <-A: Rafter Section Area (mm) 180 <-Dr: Rafter Section Height (mm) 91 <-h: Rafter Section Width (mm) 8.00 <-tf : Rafter Flange Thickness (mm) 5.30 <-tw: Rafter Web Thickness (mm) 13 169 590 <-Ix: Rafter Moment of Inertia along x-axis (mm4) 1 008 504 <-Iy: Rafter Moment of Inertia along y-axis (mm4) 146 329 <-Zx: Rafter Modulus About x-axis (mm3) 22 165 <-Zy: Rafter Modulus About y-axis (mm3) 74 <-rx: Rafter Moment radius of Gyration along x-axis (mm) 21 <-ry: Rafter Moment radius of Gyration along y-axis (mm) 19 <-Wl: Rafter Unit Weight (kg/m) Rafter Parameters Computation 5 <-E: Vertical Seismic Down Load (kg/m)

tr

wh

ts

wc

tw Dr

E = Av ( DL + DLs )

6 387 <-L: Rafter Length (mm)

L=

D Dc 2cos ( )

Y 1.67

141 <-a: Allowable Rafter Bending Stress (MPa)

a =

GHN 90 M-------K11 DC 002 C

tf

Page 28 sur 36

Rservoirs Eau Brute

Rafter Loading Computation

q2 i =

Dpi

N

q1i =

Dc pi

N

q2 ni = q2i cos ( ) q1ni = q1i cos ( )

pi (N/m)

q2ti = q2i sin ( ) q1ti = q1i sin ( )

No.

Load Case Designation

Formula

Value

q2i (N/mm) -2.54

q1i (N/mm) -0.25

q2ni (N/mm) -2.51

q1ni (N/mm) -0.25

q2ti (N/mm) -0.42

q1ti (N/mm) -0.04

(a) Fluid and Internal DL+DLs-Pi Pressure (b) Hydrostatic Pressure (c) Wind & Internal Pressure (d) Wind & External Pressure (e-1) Gravity Loads DL+DLsPt DL+DLsPU-0.4Pi DL+DLsPU+0.4Pi DL+DLs+ LL+0.4Pe DL+DLs+ Pe+0.4LL DL+DLsE-0.4Pi

-1 617.10

882.90

1.39

0.14

1.37

0.14

0.23

0.02

-1 409.51

-2.21

-0.22

-2.18

-0.22

-0.36

-0.04

-309.51

-0.49

-0.05

-0.48

-0.05

-0.08

-0.01

2 944.90

4.63

0.46

4.56

0.46

0.76

0.08

(e-2) Gravity Loads

1 917.70

3.01

0.30

2.97

0.30

0.50

0.05

(f) Seismic

-168.60

-0.26

-0.03

-0.26

-0.03

-0.04

0.00

<-pi: Design Load (N/m) <-q2i: Maximum Linear Load Applied on Rafter (N/mm) <-q1i: Minimum Linear Load Applied on Rafter (N/mm) <-q2ni: Maximum Normal Linear Load Applied on Rafter (N/mm) <-q1ni: Minimum Normal Linear Load Applied on Rafter (N/mm) <-q2ti: Maximum Compression/Tension linear load applied on Rafter (N/mm) <-q1ti: Minimum Compression/Tension Linear Load Applied on Rafter (N/mm)

GHN 90 M-------K11 DC 002 C

Page 29 sur 36

Rservoirs Eau Brute

Rafter Stresses Check

q2 + q q + q2 L 2 ni x0i = 1ni 1ni 2 ni q1ni 3 q2 ni q1ni

q x2 ( q q ) x ( 2q1ni + q2ni ) Lx0i M bi = 1ni 0i 2 ni 1ni 0 i + 2 6L 6

3

bi =

M bi Zx

ci =

( q2ti + q1ti ) L

2A

i = bi + ci

No.

Load Case Designation (a) Fluid and Internal Pressure (b) Hydrostatic Pressure (c) Wind & Internal Pressure (d) Wind & External Pressure (e-1) Gravity Loads

x0i (mm) 5 026.32

M bi (Nmm) -5 449 680

bi (MPa) 37.24

ci (MPa) 0.89

i (MPa) 38.13

Check 1i a OK

3 607.01

3 905 383

26.69

0.49

27.18

OK

5 026.32

-4 750 095

32.46

0.78

33.24

OK

5 026.32

-1 043 059

7.13

0.17

7.30

OK

3 607.01 13 026 349

89.02

1.62

90.64

OK

(e-2) Gravity Loads

3 607.01

8 482 675

57.97

1.06

59.03

OK

(f) Seismic

5 026.32

-568 196

3.88

0.09

3.98

OK

<-x0i: Abscisse of Maximum Moment (mm) <-Mbi: Maximum Moment due to Normal Loading on Rafter (Nmm) <-bi: Rafter Bending Stress (MPa) <-c: Rafter Compression/Tension Stress (MPa) <-i: Rafter due to combined bending & Compression/Tension Stress (MPa)

GHN 90 M-------K11 DC 002 C

Page 30 sur 36

Rservoirs Eau Brute

Rafter Reaction Computation & Displacement Check

5 3 3 4 q1ni x0i ( q2 ni q1ni ) x0 i ( 2q1ni + q2 ni ) Lx0i ( 7 q1ni + 8q2 ni ) L x0 i fi = + 24 EI x 120 EI x L 36 EI x 360 EI x

Rvi =

q1i + q2 i L 2

q L q Rhi = 1i + 2i 6 sin ( ) 3

No.

Load Case Designation (a) Fluid and Internal Pressure (b) Hydrostatic Pressure (c) Wind & Internal Pressure (d) Wind & External Pressure (e-1) Gravity Loads

Rvi (N) -8 923

Rhi (N) -19 737

fi (mm) 7.97

L/fi

Check L/fi 200 OK

801

4 872

10 776

-6.98

915

OK

-7 778

-17 203

6.95

919

OK

-1 708

-3 778

1.53

4 186

OK

16 250

35 943

-23.28

274

OK

(e-2) Gravity Loads

10 582

23 406

-15.16

421

OK

(f) Seismic

-930

-2 058

0.83

7 683

OK

<-Rvi: Vertical Shell Reaction (N) <-Rhi: Radial Load on Compression Ring & Shell Stiffener (N) <-fi: Maximum Rafter Displacement (mm)

GHN 90 M-------K11 DC 002 C

Page 31 sur 36

Rservoirs Eau Brute

Compression Ring Parameters Computation 182 <-b: Compression Ring Box Height (mm)

b=

Dr cos ( )

6 050 <-Acr: Compression Ring Box Cross Section Area (mm)

Acr = 2atcr + 2 ( b 2tcr ) tcr

4 18 330 217 <-Icry: Compression Ring Box Section Moment of Inertia Along y-Axis (mm )

I cry =

ba 3 ( b 2tcr )( a 2tcr ) 12

3 309 228 <-Zcry: Compression Ring Box Section Modulus Along y-Axis (mm )

Z cry =

ba 2 ( b 2tcr )( a 2tcr ) 4

13 <-: Angle Between Rafters (Deg)

360 N Dc a 2

630 <-Rc: Compression Ring Mean Radius (mm)

Rc =

0.992 <-k2: Compression Ring Hoop Stress Deformation Factor

k2 = 1

I ycr Acr Rc2

141 <-cra: Allowable Stresses for Compression Ring (MPa)

cra =

Ycr 1.67

GHN 90 M-------K11 DC 002 C

Page 32 sur 36

Rservoirs Eau Brute

Compression Ring Stresses Check

N pi =

Rhi 4sin 2

M pi =

Rhi Rc 2

k2 1 tan ( )

pi =

mi =

M pi Z cry

N pi Acr

Rhi N mi = 2sin ( )

M mi

R R 1 k = hi c 2 2 sin ( )

Npi (N) -19 924 M pi (Nmm) 255 101 Nmi (N) -20 050

M mi N + mi Z cry Acr

cri = Max ( pi ; mi )

M mi (Nmm) -445 398 pi (MPa) 4 mi (MPa) 5 cri (MPa) 5 Check cri cra OK

No.

Load Case Designation (a) Fluid and Internal Pressure (b) Hydrostatic Pressure (c) Wind & Internal Pressure (d) Wind & External Pressure (e-1) Gravity Loads

10 878

-139 280

10 947

243 177

OK

-17 366

222 354

-17 476

-388 222

OK

-3 813

48 826

-3 837

-85 248

OK

36 283

-464 565

36 513

811 115

OK

(e-2) Gravity Loads

23 627

-302 522

23 777

528 193

OK

(f) Seismic

-2 077

26 597

-2 090

-46 438

OK

<-Npi: Axial Effort Applied to Compression Ring at Point Load (N) <-Mpi: Bending Moment Applied to Compression Ring at Point Load (Nmm) <-Nmi : Axial Effort Applied to Compression Ring at Mid Point (N) <-Mmi : Bending Moment Applied to Compression Ring at Mid Point (Nmm) <-pi: Compression Ring Bending & Axial Stress at Point Load (MPa) <-mi : Compression Ring Bending & Axial Stress at Mid Point (MPa) <-cri: Compression Ring Maximum Bending & Axial Stress (MPa)

GHN 90 M-------K11 DC 002 C

Page 33 sur 36

Rservoirs Eau Brute

Shell Compression Ring Parameters

trc

XRP r

wh

tsc XSP

42 579 <-R2: Length of the Normal to the Roof Measured from the Verical Centerline (mm)

R2 =

D 2sin ( )

138 <-wh: Maximum Width of Participating Roof (mm)

wh = Min 300; 0.3 R2 ( tr Cr )

87 <-wc: Maximum Width of Participating Shell (mm)

wc = 0.6

130 4 720 000 3 000 94 1 075 282

D ( t s Cs ) 2

<-aS: L Shape Height (mm) <-IyS: L Shape Neutral Axis Moment of Inertia Along y-Axis (mm4) <-AS: L Shape Section Area (mm) <-XS: L Shape Neutral Position (mm) <-IyRP: Roof Plate Neutral Axis Moment of Inertia Along y-Axis (mm4)

( tr Cr ) wh3 cos + wh ( tr Cr ) I yRP = ( )

12 12

692 <-ARP: Roof Plate Section Area (mm)

wc

sin ( )

ARP = ( tr Cr ) wh

178 <-XRP: Roof Plate Neutral Position (mm)

X RP = aS r +

wh cos ( ) 2

3

196 <-IySP: Shell Plate Neutral Axis Moment of Inertia Along y-Axis (mm4)

I ySP =

wc ( ts Cs ) 12

GHN 90 M-------K11 DC 002 C

Page 34 sur 36

Rservoirs Eau Brute

261 <-ASP: Shell Plate Section Area (mm)

ASP = ( ts Cs ) wc

132 <-XSP: Shell Plate Neutral Position (mm)

X SP = aS +

( t s Cs )

2

3 953 <-Aco: Shell Compression Ring Cross Section Area (mm)

Aco = As + ARP + ASP

111 <-Xco: Compression Ring Plate Neutral Position (mm)

X co =

X RP ARP + X SP ASP + X S AS Aco

2 2 2

9 945 277 <-Iyco: Shell Compression Ring Moment of Inertia Along y-axis (mm4)

I yco = I yRP + ARP ( X co X RP ) + I ySP + ASP ( X co X SP ) + I yS + AS ( X co X S )

73 336 <-Zyco: Shell Compression Ring Section Modulus Along y-Axis (mm3)

7 000 <-R: Shell Compression Ring Mean Radius (mm)

I yco I yco Z yco = Min ; X a r + w cos ( ) X h co co S

R= D 2

1.000 <-k2o: Shell Compression Ring Hoop Stress Deformation Factor

k2 o = 1

I yco Aco R 2

141 <-coa: Allowable Stresses for Shell Compression Ring (MPa)

coa =

Yco 1.67

GHN 90 M-------K11 DC 002 C

Page 35 sur 36

Rservoirs Eau Brute

Shell Compression Ring Stresses Check

N poi =

Rhi 4 sin 2

M poi

R Rk 1 = hi 2 2 tan ( )

poi =

moi =

M poi Z coy

N poi Aco

N moi

Rhi = 2sin ( )

Load Case Designation

M moi =

Rhi R 1 k 2 2 sin ( )

M poi (Nmm) 2 834 460 Nmoi (N) -20 050

M moi N + moi Z coy Aco

coi = Max ( poi ; moi )

M moi (Nmm) -4 948 870 poi (MPa) 44 moi (MPa) 73 coi (MPa) 73 Check cri cra OK

No.

Npoi (N) -19 924

(a) Fluid and Internal Pressure (b) Hydrostatic Pressure (c) Wind & Internal Pressure (d) Wind & External Pressure (e-1) Gravity Loads

10 878

-1 547 551

10 947

2 701 971

24

40

40

OK

-17 366

2 470 595

-17 476

-4 313 575

38

63

63

OK

-3 813

542 510

-3 837

-947 205

14

14

OK

36 283

-5 161 834

36 513

9 012 385

80

132

132

OK

(e-2) Gravity Loads

23 627

-3 361 353

23 777

5 868 807

52

86

86

OK

(f) Seismic

-2 077

295 527

-2 090

-515 980

OK

<-Npoi: Axial Effort Applied to Outside Compression Ring at Point Load (N) <-Mpoi: Bending Moment Applied to Outside Compression Ring at Point Load (Nmm) <-Nmoi: Axial Effort Applied to Outside Compression Ring at Mid Point (N) <-Mmoi: Bending Moment Applied to Outside Compression Ring at Mid Point (Nmm) <-poi: Outside Compression Ring Bending & Axial Stress at Point Load (MPa) <-moi: Outside Compression Ring Bending & Axial Stress at Mid Point (MPa) <-coi: Outside Compression Ring Maximum Bending & Axial Stress (MPa)

GHN 90 M-------K11 DC 002 C

Page 36 sur 36

Vous aimerez peut-être aussi

- Baremage de Reservoirs de Stockage Fc025Document1 pageBaremage de Reservoirs de Stockage Fc025macao100100% (1)

- PQR/WPSDocument148 pagesPQR/WPSadel bengharbiPas encore d'évaluation

- Guide Canalisations PDFDocument134 pagesGuide Canalisations PDFessamyPas encore d'évaluation

- PR Ehs Gr6 Pc03-Ta Rév eDocument34 pagesPR Ehs Gr6 Pc03-Ta Rév ekarech mounir100% (5)

- DesignDocument19 pagesDesignMhd OuakPas encore d'évaluation

- Bride D'ancrage ExecutionDocument9 pagesBride D'ancrage ExecutionMed Samai83% (6)

- Guide Sablage Et Peinture Antico TopDocument67 pagesGuide Sablage Et Peinture Antico TopAchraf Bouziane100% (1)

- Dossier InterventionDocument60 pagesDossier InterventiontroisvirgulePas encore d'évaluation

- Tableau Volume FondDocument2 pagesTableau Volume FondazizkhouribgaPas encore d'évaluation

- AFIAP CTP Reservoirs Sous Talus Juil 04 Rev1Document9 pagesAFIAP CTP Reservoirs Sous Talus Juil 04 Rev1Anonymous 24lnhhPas encore d'évaluation

- Codeti 2001Document662 pagesCodeti 2001mohammed addalaPas encore d'évaluation

- Reglementation PressionDocument40 pagesReglementation PressionImane Mjimer100% (1)

- DT 110 Partie C Guides Réservoirs de Stockage AtmosphériquesDocument21 pagesDT 110 Partie C Guides Réservoirs de Stockage AtmosphériquesmlamourPas encore d'évaluation

- Bras de Chargement 1Document37 pagesBras de Chargement 1Salah JallaliPas encore d'évaluation

- Guide Professionnel GESIP 2007.05 - Edition de Janvier 2014 PDFDocument130 pagesGuide Professionnel GESIP 2007.05 - Edition de Janvier 2014 PDFNa Rjis100% (1)

- NF en 14015Document1 pageNF en 14015elamigosolitarioPas encore d'évaluation

- Plan m18 RESERVOIR PDFDocument2 pagesPlan m18 RESERVOIR PDFBouraoui Ben AyedPas encore d'évaluation

- Catalogue Tuyauterie Devauze2005Document16 pagesCatalogue Tuyauterie Devauze2005aamenaPas encore d'évaluation

- Les Cables Des Remontees Mecaniques1 PDFDocument122 pagesLes Cables Des Remontees Mecaniques1 PDFpreslePas encore d'évaluation

- Réservoir de StockageDocument4 pagesRéservoir de StockagePeter Bird67% (3)

- Rouibet, SidaliDocument197 pagesRouibet, SidaliYøü ČęfPas encore d'évaluation

- Rapport D'expertise Schneider Rev01Document28 pagesRapport D'expertise Schneider Rev01Touil HoussemPas encore d'évaluation

- Poteau D'incendie A120-A125Document4 pagesPoteau D'incendie A120-A125YOUDBIB Youssef100% (1)

- A1. Note de Calcul Du Ru00E9servoir Mu00E9tallique - Diamu00e8tre 100 Mu00B3Document14 pagesA1. Note de Calcul Du Ru00E9servoir Mu00E9tallique - Diamu00e8tre 100 Mu00B3YacoudimaPas encore d'évaluation

- GIL Mise Sous Talus V1Document9 pagesGIL Mise Sous Talus V1dieego001Pas encore d'évaluation

- Procedure DP Lala Abdia 8x40 GZ1Document17 pagesProcedure DP Lala Abdia 8x40 GZ1Tayyeb Ouis100% (1)

- Réservoirs À Toit FixeDocument4 pagesRéservoirs À Toit FixeSaad Doukali100% (1)

- GLPFDocument48 pagesGLPFSalah Jallali100% (1)

- Procedure Boite À VideDocument6 pagesProcedure Boite À VideHocine Chekroun100% (1)

- PCI-PR-04-04 Procedure Epreuve Hydraulique Officielle Akram ApprouvéDocument13 pagesPCI-PR-04-04 Procedure Epreuve Hydraulique Officielle Akram ApprouvéomarPas encore d'évaluation

- General Brochure (FR)Document4 pagesGeneral Brochure (FR)Mukiara LuffyPas encore d'évaluation

- Section DDocument142 pagesSection DyosriPas encore d'évaluation

- Ecran Flottant Interne - LARCO PDFDocument1 pageEcran Flottant Interne - LARCO PDFSacre EwaPas encore d'évaluation

- ConceptionDocument37 pagesConceptionArajaaePas encore d'évaluation

- Defauts de Soudure - CouleurDocument15 pagesDefauts de Soudure - CouleurFethi BELOUISPas encore d'évaluation

- Les Reservoirs de StockageDocument13 pagesLes Reservoirs de StockageAkram BELHADJPas encore d'évaluation

- Pont Roulant Et PortiqueDocument2 pagesPont Roulant Et PortiqueHasnaoui AsmaaPas encore d'évaluation

- Data Sheet Rev0 Inspection FourDocument17 pagesData Sheet Rev0 Inspection Fourenact uraPas encore d'évaluation

- 10420-SAR-CI-CN-001-01-Note de Calcul Fondation Du Réservoir T-506Document12 pages10420-SAR-CI-CN-001-01-Note de Calcul Fondation Du Réservoir T-506Bilel MahjoubPas encore d'évaluation

- Codes Et Normes ApiDocument3 pagesCodes Et Normes ApiAlexandra moussi PaolaPas encore d'évaluation

- EquipementsDocument83 pagesEquipementsaminPas encore d'évaluation

- Cours Corrosion-Partie 3 PDFDocument24 pagesCours Corrosion-Partie 3 PDFCris GauchoPas encore d'évaluation

- Norme 109-14Document84 pagesNorme 109-14Le Bacha BachaPas encore d'évaluation

- Aide Memoire Api 650Document19 pagesAide Memoire Api 650Saïd EL GHANDOURPas encore d'évaluation

- Essais HydrostatiquesDocument52 pagesEssais Hydrostatiquesمحترف من عالم آخرPas encore d'évaluation

- Socle PompeDocument1 pageSocle PompeomarPas encore d'évaluation

- CCTG AEP - Tome 1 - Equipements - Version 1 (Octobre 2012) - OnEE-Branche EauDocument93 pagesCCTG AEP - Tome 1 - Equipements - Version 1 (Octobre 2012) - OnEE-Branche EauNouna Bing100% (1)

- 10.soudure Au PlatreDocument17 pages10.soudure Au Platreabdellah100% (1)

- Standard Log 049 - 00 - Inspection Des Tuyauteries HydrocarburesDocument10 pagesStandard Log 049 - 00 - Inspection Des Tuyauteries HydrocarburesTeddy Smith100% (1)

- Normes Internationales Appareils de LevageDocument3 pagesNormes Internationales Appareils de LevagerezokaPas encore d'évaluation

- CCTP Equi Forage Base AerienDocument23 pagesCCTP Equi Forage Base AerienBen Hssen SaberPas encore d'évaluation

- RéservoirDocument11 pagesRéservoirAnonymous YgEKXgWPas encore d'évaluation

- RéservoirDocument11 pagesRéservoirtraore zachariePas encore d'évaluation

- 15 Fers A BetonDocument25 pages15 Fers A BetongvmepdfPas encore d'évaluation

- Asme B31.3Document5 pagesAsme B31.3tassioPas encore d'évaluation

- Joint Pont Cipec WPDocument20 pagesJoint Pont Cipec WPfanion47Pas encore d'évaluation

- Cour 2Document24 pagesCour 2Houssem Eddine HizemPas encore d'évaluation

- Note de Calcul Gare de Racleur Depart ExecutionDocument9 pagesNote de Calcul Gare de Racleur Depart ExecutionMed SamaiPas encore d'évaluation

- Joint Pont Gts 160-300Document16 pagesJoint Pont Gts 160-300fanion47Pas encore d'évaluation

- C9620 ST607 Rev.0Document28 pagesC9620 ST607 Rev.0Joseph MidouPas encore d'évaluation