Académique Documents

Professionnel Documents

Culture Documents

VPFW 979002 - C - Operation Follow Up Procedure

Transféré par

turkayTitre original

Copyright

Formats disponibles

Partager ce document

Partager ou intégrer le document

Avez-vous trouvé ce document utile ?

Ce contenu est-il inapproprié ?

Signaler ce documentDroits d'auteur :

Formats disponibles

VPFW 979002 - C - Operation Follow Up Procedure

Transféré par

turkayDroits d'auteur :

Formats disponibles

Valenciennes

AFFAIRE :

CONCERNING : CITADIS ISTANBUL

N° Identification Client N° Identification VPF

Customer identification number VPF identification number

VPFW 979 002

Type de document

Document type

Reliability note

Titre

Title

Reliability and availability operation

monitoring procedure

Langue d’origine :

WP : PBS :

Origin language: English

ébauche pour consultation bon pour application ✘ confidentiel

draft for consultation for application confidential

FONCTION NOM DATE SIGNATURE

FUNCTION NAME DATE SIGNATURE

REDIGE PAR RAMS project M. MORCHIDE.

WRITTEN BY manager CHUETTE

VERIFIE PAR RAM manager J-M. LEFEBVRE

VERIFIED BY

APPROUVE PAR RTP N. GARDASJ. COPIN

APPROVED BY

APPROUVE PAR PM L. DARMONM.

APPROVED BY WURSTEISEN

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 1/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

SUIVI DES MODIFICATIONS

MODIFICATION FOLLOW UP

Rév. Page/Chapitre Rédact./Date Désignation succincte de la modification

Rev. Sheet/Chapter Writter/Date Summarized designation of the modification

0 M. MORCHID CREATION

A M.MORCHID Update within Ulasim/Alstom meeting on 30/09/10

B M Wursteisen Update pages 7-8

C M Wursteisen Update following Ulasim comments Jan 2012

CONTENT

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 2/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

ABBREVIATIONS.............................................................................................................................................................4

1 INTRODUCTION.....................................................................................................................................................5

1.1 PURPOSE..............................................................................................................................................................5

1.2 SCOPE..................................................................................................................................................................5

2 REFERENCES..........................................................................................................................................................6

2.1 CUSTOMER DOCUMENTATION.............................................................................................................................6

2.2 ALSTOM DOCUMENTATION..................................................................................................................................6

2.3 REFERENCE DOCUMENTATION.............................................................................................................................6

3 ORGANIZATION.....................................................................................................................................................7

3.1 OPERATION MONITORING UP COMMISSION..........................................................................................................7

3.2 DATA GATHERING...............................................................................................................................................7

3.3 ANALYSIS OF ALSTOM DATABASE...................................................................................................................8

4 RELIABILITY.........................................................................................................................................................10

4.1 DEFINITIONS......................................................................................................................................................10

4.2 CONTRACTUAL RELIABILITY REQUIREMENT.....................................................................................................11

5 CONTRACTUAL COUNTING OF FAILURES.................................................................................................13

5.1 INTRODUCTION..................................................................................................................................................13

5.2 COUNTING RULES..............................................................................................................................................13

6 AVAILABILITY......................................................................................................................................................15

6.1 DEFINITION........................................................................................................................................................15

6.2 MEASUREMENT.................................................................................................................................................15

6.3 RULES................................................................................................................................................................15

7 SERIAL DEFETCS.................................................................................................................................................16

7.1 CONTRACTUAL DEFINITION...............................................................................................................................16

7.2 METHOD OF CALCULATIONS.............................................................................................................................16

8 MTBF Calculation method........................................................................................................................................17

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 3/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

ABBREVIATIONS

ATSA ALSTOM Transport SA

C&W Commissioning & Warranty

MTBF Mean Time Between Failures

MTBSF Mean Time Between Service Failures

MKBF Mean Kilometers Between Failures

NNFNFF No Fault Found

OCC Operation Control Center

RAM Reliability, Availability, and Maintainability.

RAMS Reliability, Availability, Maintainability, and Safety.

RS Rolling Stock

SU/MU Single Unit / Multiple Unit

TCMS Train Control and Monitoring System

VPF ALSTOM Valenciennes

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 4/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

1 INTRODUCTION

1.1 PURPOSE

The purpose of this document is to describe the methodology used for the operation follow up of the

ISTANBUL Tram rolling stock. The C&W and RAM engineer in charge of the reliability

monitoring in agreement with Ulasim will use it.

1.2 SCOPE

This procedure is applicable to the entire Rolling Stock, including all train borne systems. The

limits of the Rolling Stock system are given by its breakdown and interfaces.

This document is applicable for 37 tramways 301 NG

Kilometres predicted: 70 000 km/year/tram

Operation configuration: SU or MU

This procedure, and in particularly, the reliability and availability targets that are defined, is

applicable on ALSTOM Rolling Stock, and not on Ulasim supply

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 5/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

2 REFERENCES

2.1 CUSTOMER DOCUMENTATION

[A1]: CBC-Istanbul-rev.H- 29 July 2007

[A2] : CONTRACT FOR PROCUREMENT OF 30 EA. LOW FLOOR TRAMWAY VEHICLES

AND 1 EA. VEHICLE TRAINING SIMULATOR FOR ISTANBUL KABATAS-

ZEYTINBURNU- BAGCILAR LINE

2.2 ALSTOM DOCUMENTATION

[B1]: Functional Breakdown Structure VPFW 972 002

[B2]: RAM plan management VPFW 972 001

[B-3]: Reliability Preliminary analysis VPFW 979 001

2.3 REFERENCE DOCUMENTATION

[C1]: Standard EN 50126

[C2]: NF F01 305

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 6/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

3 ORGANIZATION

3.1 OPERATION MONITORING UP COMMISSION

A commission to analyse the reliability and availability performances will be set up with Ulasim

and ALSTOM staff after the delivery of the last trampreliminary acceptance of all trams (37th

tramway). This commission will be maintained

The first reliability meeting will take place each 3 months after the preliminary acceptance of all

trams. If the reliability targets are not demonstrated, the reliability meeting will be maintained each

month, until the targets are achieved.

The first availability meeting will take place 12 months after start of the revenue service. If the

availability target is not demonstrated, the availability meeting will be maintained each month, until

the target is achieved

The purpose of this commission is:

- To validate the contradictory checking of all failure descriptions happened during

operation, and to identify failures that are imputable to rolling stock

- To calculate the contractual reliability and availability parameters: MTBF and ,

MTBSF and availability

- To analyse serial defects

3.2 DATA GATHERING

The event descriptions are transmitted from the driver to the OCC, and then Ulasim registers them.

This record: The Event Information Form will has been be defined in agreement between Ulasim

and ALSTOM (IFR form). This notice has to containcontains at least those information:

- N° reference of the OCC that registers the event

- Date and hour of the event

- Identification of the tram, cab in service, and the concerned element: M1, NP, M2

- N° of mission/service

- Place where the failure was raised

- Information concerning the failure (what has been noticed and/or what has been read

on the DDU)

- Type of operation disturbance in accordance with the preliminary reliability analysis

[B5B3]

- Kilometers

- Hours in counters

In multiple unit configuration, those information must be for each tram (each single unit).

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 7/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

The events are recorded by Ulasim in the workshop (depot). For each event, when the

responsibility of the rolling stock constructor is proven, this notice has to be sent to the C&W of

ALSTOM for intervention. The record of the event has to be accompanied with the defects

memorised in the concerned equipments: it has to be communicated to the C&W within 18

hours after the observation of the anomaly. In case of overrunning of 48 hours, the event won’t

be taken into account, and won’t be part of MTBF or MTBSF calculations.

C&W will immediately enter the results of corrective maintenance interventions in ALSTOM

database.

A monthly report of reliability parameters MTBF and MTBSF will be set up by ALSTOM and

communicated to ULASIM during warranty period.

3.3 ANALYSIS OF ALSTOM DATABASE

The data will be analysed by Alstom and Ulasim periodically in order to:

Set up an harmonization of the data by filtering and attribution of the events using the knowledge of

interventions’ causes and results

A daily meeting between ALSTOM C&W and Ulasim representative, to make decisions about the

litigations identified: responsibility of events that are not agreed between ALSTOM and Ulasim.

The event in litigation mode will not be counted in contractual reliability calculations

To make fast decisions about the interventions, and to be as efficient as possible in anomaly

treatments.

ALSTOM database is analysed by the reliability department of VPF.

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 8/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

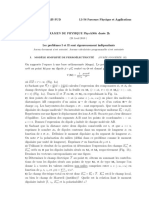

Driver

PCC

Record of the events Ulasim events

RS Responsability

Not RS responsibility Depot

filtering

C&W

Daily meetings

Intervention

between C&W

ALSTOM

Data entry by

C&W

Intervention notice to

Ulasim database Data base Record of

interventions and

events

ALSTOM Analysis of data by VPF

Reliability entity

and Ulasim

Database

treatment and

calculation of

reliability

parameters by

VPF

Reliability follow

up entity

Diagram of gathering, analysis and treatment of feedback data

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 9/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

4 RELIABILITY

4.1 DEFINITIONS

Reliability

The probability that an item can perform a required function under given conditions for a given time

interval

Failure

The inability of a system or component to fulfil its operational requirements. Failures may be

systematic or due to physical change.

MTBF

The MTBF (Mean Time Between Failure) is the mean time in hours traveled by a vehicle in

good working order between two fault events.

The MTBF is calculated according to the following formula:

Where: T1 is the total time of the trains operating,

N1 is the number of failures of the trains occurred in time T1.

MTBSF

The MTBSF (Mean Time Between Service Failure) is the mean time in hours traveled by a

vehicle in good working order between two fault events that impact the service.

The MTBF is calculated according to the following formula:

Where: T1 is the total time of the trains operating,

N1 is the number of failures of the trains occurred in time T1.

MKBF

The MKBF (Mean Kilometer Between Failure) is the mean distance in kilometers traveled

by a vehicle in good working order between two fault events.

The MKBF is calculated according to the following formula:

MKBF = Distance traveled by fleet in service

Total number of fleet faults

Failure rate (k)

This is defined by the following formula:

k = 1/MKBF

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 10/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

Tramway in service

A tramway that fulfils or ready to fulfil its operation planning. It can be an operation with

passengers or waiting to start at end of line (terminus).

Tramway is in service if the driver enters the mission number.A tramway is in service as from the

moment when the ignition key is placed to start the car for operation until the car is taken out of

service (ignition key is removed)

Wake up of a tramway

The tramway is waked up if all equipments are under voltage and have been tested. The tram is

activated by the driver and is waiting for the service mission.

4.2 CONTRACTUAL RELIABILITY REQUIREMENT

4.2.1 Definition of the contractual reliability parameters

The contractual parameters that will be calculated are: MTBF and MTBSF for a single unit

All failures under Classes A, B, C, D and E shall be applicable for the MTBF calculations, and only

Type A, B and C failures shall be taken into account in MTBSF calculations.

A: failures leading to rescue (towing/pushing)in which the car cannot move and the car has to be

towed as spare

B: failures leading to Return to Depot after evacuation of passengersthat require evacuation of

passengers, but that the car can go to the depot with its own power

C: failures leading to end of linethat do not require evacuation of passengers , but specific failures

that are found as obstacles for service by Istanbul Administration

D: failures leading to end of day and doesn’t impact the servicein which the car can continue

service until the end of the day

E: failures that can be treated at next maintenanceare repairable until the next maintenance

4.2.2. Reliability targets

Reliability targets are as per [B4B2]

4.2.3 Hypothesis taken into account for reliability calculations

The MTBF and MTBSF targets are for the whole fleet of 37 tramways.

The MTBF and MTBSF will be calculated each month for the whole fleet, taken to account

the information of: failures of the fleet and operation hours of the fleet of the three sliding

months.

The operation hours calculated is the sum of the operation hours of 37 tramways, single

units hours will be taken into account.

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 11/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

The calculations are based on 70 000 km/year/unit and 17km/h as average speed.

If those hypotheses below are not respected, the MTBF and MTBSF will be re evaluated.

The date of deliverypreliminary acceptance of the last tramway is the date of beginning of

the contractual reliability monitoring

For reliability calculations, each tramway has to exceed its first 10 000 Km: period of burn-

in. failure for tram not exceeding 10 000km, as burn in criteria , will not be taken into

account.

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 12/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

5 CONTRACTUAL COUNTING OF FAILURES

5.1 INTRODUCTION

The reliability measures are based on organic and functional failures.

The failures related to Ulasim equipment are not part of the measures; in particular the track point

antenna and radio track system are not part of ALSTOM supply.

5.2 COUNTING RULES

5.2.1 Case of the period before a corrective maintenance operation

During the period before a corrective maintenance operation, a same failure in the same tram at the

same equipment will be calculated one time even if we have several events according to that failure.

5.2.2. Case of resulting failures

The event should have one organic cause. The failures caused by other equipment or other tram will

not be taken to account.

5.2.3. Case of modification

Three dates will be taken in account

A: date of first failure

B: date of decision of retrofit (modification)

B’: date of validation of solution, modification

C: date of application of modification on one tram

Counting No counting Back to counting of trams modified

A B B’ C

A failure will not be taken to account at the beginning of application of ALSTOM modification

5.2.4. Case of repeating NFF

- Determination of a repeating NFF:

An event, that appears at the same equipment or function (if the equipment is not identified) at the

same tram, and has the same symptom, will be considered as a repeating event if it appears 1 weeks

after the first event.

- Counting of NFF:

o A NFF failure is counted if it is a repeating NFF and is ALSTOM responsibility.

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 13/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

o After 1 week, a repeating NFF is counted as a new NFF.

o A NFF failure that requires the defects memorised and recorded, will not be counted

if the records were not send at the right time

o A NFF failure, which memorised defects show that the failure is not ALSTOM

responsibility, will not be part of calculations

o A NFF failure according to an event that is not well described and not repeated

during line tests or maintenance will not be part of calculations

o Only NFF failures that have a well described event, memorised defects and has an

impact on service will be part of calculations

5.2.5. Case of failures caused by a non respect of maintenance plan

The usury of equipments has to be detected at preventive maintenance or during daily tests.

Failures caused by usury will not be part of calculations because they are considered as non-respect

of maintenance plan.

5.2.6. Case of bad adjustment

Failures caused by bad adjustments will not be part of calculations except if equipments have

systematic bad adjustments.

5.2.7. Case of storage

Failures caused by bad storage of equipments will not be part of calculations.

5.2.8. Case of maintenance or operation errors

Failures caused by an error of maintenance worker (during corrective or preventive maintenance) or

driver will not be part of calculations.

5.2.9. Case of failures out of operation

The operation zone: T1 and T2 zones. Failures observed out of this zone will not be part of

calculations.

Out of T1 and T2, failures occurring in section of LRT line between Zeytinburnu and Esenler are

counted in the MTBF and not in the MTBSF.

5.2.10. Case of exclusions

The management of these failures are not part of the reliability monitoring

Vandalism failures

Non-respect of maintenance process

Failures caused by traffic accidents that are not caused by a vehicle’s failure.

Conditions of the train operation that are not specified in the contract

Ulasim equipments

Particular climatic conditions

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 14/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

6 AVAILABILITY

6.1 DEFINITION

- Availability is the ratio of the realized number of travels to the planned number of travels.

Precision: Considering a train not available due to curative maintenance is not counted (i.e. a train

in preventive maintenance is considered as being available for service).

- The fleet of 37 cars shall be operated in the arrangements of 2 sets according to [A1]

- The availability of the remaining sets shall be minimum 99% during peak hours.

- The peak hours are during 07.30 – 10.00 a.m. and 05.00 – 08.30 p.m.

6.2 MEASUREMENT

- Measurements will start 12 months after revenue service start: at T0 + 12

- Each day: from Monday to Sunday, we consider the peak hours: 07.30 – 10.00 a.m. and 05.00 –

08.30 p.m.

- We consider 17 sets: multiple unit configuration because we have 37 tramways and three vehicles

as spares in depot. 17 = (36-2)/2

- Availability per day: (travels realised between 07.30 – 10.00 a.m + travels realised between 05.00

– 08.30 p.m). / (travels planned between 07.30 – 10.00 a.m + travels planned between 05.00 – 08.30

p.m )

- Average aAvailability will be calculated monthly., until the target is demonstrated

6.3 RULES

6.3.1. Case of Ulasim equipments

If a set is not available due to Ulasim equipments; this set will not be part of availability

calculations.

6.3.2. Case of preventive maintenance

The preventive maintenance operations shall not be planned at peak hours defined according to

[A1].

6.3.5. Case of exclusions

Sets not available for those reasons will not be part of availability calculations:

- Accidents

- Vandalism

- Ulasim immobilization of sets

- Strike

- Conditions of sets operation that are not specified in the contract

- Particular climatic conditions

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 15/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

7 SERIAL DEFETCS

7.1 CONTRACTUAL DEFINITION

If the same fault occurs on the same parts and components (these parts are indicated below) that

have the same function at minimum 15% (related to all tramway vehicles) within 5 years following

the preliminary acceptance, this fault shall be regarded as a Serial Defect. In case of serial defect,

the Contractor shall inspect all the related parts and provide a technical solution for remedial of the

defect with all costs on account of him. This solution provided by the contractor shall be put into

application after being approved by the contracting entity and the serial defect shall be remedied

free of charge.

Parts and components to be regarded within the scope of serial defect are as follows;

- Car body, main structure and connections (rivets, bolts and welds)

- Bottom flooring

- Bogies and all under frame equipment

- Axles, axle bearings, wheels

- Traction motors and gearboxes

- Brake calipers.

7.2 METHOD OF CALCULATIONS

- Calculations of the serial defects will be done each 12 months beginning at the date of delivery of

the last car

- The serial defects will be calculated on the components defined above § 7.1 within the 37 trams

- The ratio of serial defects shall not exceed 15%: counting will be for defects of same nature on

same equipment, counting the [number of same equipments presenting defect of the same nature /

number of same equipments on the fleet],defects of same nature on same equipment / number of

same equipments on the fleet

- Only components defined above § 7.1 will be analysed.

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 16/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

8 MTBF CALCULATION METHOD

The reliability parameters are calculated based on N FF 01305.

Extract from NFF 01305:

<MTBF> = T / c

avec,

T : Number of operating hours of the fleet,

c : Number of failures obesreved during this period.

With a probability fixed p=1-

This probability p is generally fixed at 60%, that means a risk to have the MTBF lower than the one given by

the upper bound <sup> of the interval is equal to :

= 20%.

The estimator repects an exponential law, the low and upper bounds of the MTBSF are estimated by the

formula following :

Upper bound : = = MTBFsup

Lower bound : = = MTBFinf

is the distribution law of the khi – deux.

The failure rates are defined as following :

< h >= ; ;

A reliability target will be stated as not respected if it’s not bordered by the confidence interval, that means:

h inf = > h objectif

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 17/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Valenciennes

The practical identification of the is determined as following :

Zp 3

, avec : Zp=0,84162

The reliability indicator calculation will be done each month on three sliding months.

Processus amont ENG-VPF-PRO-014 Référence modèle ENG-VPF-FRM-245 rév 0

Titre N° Identification VPF Révision N° Pages :

Title VPF identification number Revision Nr Pages :

Reliability and availability Operation monitoring procedure VPFW 979 002 AC 18/ 18

© 2007 - ALSTOM Transport SA Ce document et les informations qu'il comprend sont la propriété exclusive d'ALSTOM Transport SA

Toute publication, reproduction, présentation, adaptation, traduction sont interdites sans l'accord écrit d'ALSTOM Transport SA.

Vous aimerez peut-être aussi

- Modèle Protocole QP PSMDocument28 pagesModèle Protocole QP PSMAzeddine LA100% (3)

- AQUAP 2019 04 Rev3Document16 pagesAQUAP 2019 04 Rev3Emmanuel BoquetPas encore d'évaluation

- OR1SPE-2.1-D300-TIS-0004-A1 HW Specification - CLCDocument36 pagesOR1SPE-2.1-D300-TIS-0004-A1 HW Specification - CLCNiceMen SafaniPas encore d'évaluation

- 52 Manuel Moteur FocsDocument106 pages52 Manuel Moteur Focsna100% (1)

- Procedure de SoudageDocument8 pagesProcedure de SoudageHocine ChekrounPas encore d'évaluation

- Procédure D'execution Des TerrassementsDocument6 pagesProcédure D'execution Des TerrassementsPatrick Vivian NGOAMBE100% (1)

- 28/04/2016 Smain: TR Document Number: TR Numéro Du Document: REV. 05Document24 pages28/04/2016 Smain: TR Document Number: TR Numéro Du Document: REV. 05Bn BnPas encore d'évaluation

- 10 - CUBES Qualité - Plan de Surveillance Plaque DecantationDocument3 pages10 - CUBES Qualité - Plan de Surveillance Plaque DecantationAlexisPas encore d'évaluation

- 05 TC - Informations de Synthèse PDFDocument54 pages05 TC - Informations de Synthèse PDFBouzaida Maher100% (1)

- Audit Safe Portee InspectionDocument8 pagesAudit Safe Portee InspectionRim BdidaPas encore d'évaluation

- Manuel de Procedure v1 CADocument188 pagesManuel de Procedure v1 CAathauraPas encore d'évaluation

- 4760 Omnivista TCV013frDocument78 pages4760 Omnivista TCV013frdahvsatPas encore d'évaluation

- Referentiel Marque Fenetre Et Bloc BaieDocument73 pagesReferentiel Marque Fenetre Et Bloc Baieda sasaPas encore d'évaluation

- Tuyau Beton Référentielroctobre 2011version4Document99 pagesTuyau Beton Référentielroctobre 2011version4Yazid AbdelfettahPas encore d'évaluation

- 511 A - Fap - TransfoDocument5 pages511 A - Fap - TransfoelissaminoPas encore d'évaluation

- Référentiel de Certification AC-REF-001-02 - C - by - Apave - MachinesDocument30 pagesRéférentiel de Certification AC-REF-001-02 - C - by - Apave - MachinesMaïga YoussouphPas encore d'évaluation

- Cer Rob013Document3 pagesCer Rob013MORELLI silvioPas encore d'évaluation

- FLOWSERVE - Manuel D'installation & D'exploitation PDFDocument78 pagesFLOWSERVE - Manuel D'installation & D'exploitation PDFFredericVaianaPas encore d'évaluation

- Manuel de Procedures IPV Ver1.1 Nov 2015 PDocument71 pagesManuel de Procedures IPV Ver1.1 Nov 2015 PAminePas encore d'évaluation

- Manuel de Procedures IPV Ver1.1 Nov 2015 P PDFDocument71 pagesManuel de Procedures IPV Ver1.1 Nov 2015 P PDFBILPas encore d'évaluation

- Certificat Gamme VRDocument1 pageCertificat Gamme VRJean-Philippe MailletPas encore d'évaluation

- Tram InstructionDocument8 pagesTram Instructionhind BELMAYZIPas encore d'évaluation

- Rpifingma20140004 - FR - v3 1 - RmadDocument25 pagesRpifingma20140004 - FR - v3 1 - RmadAlexis NiviaPas encore d'évaluation

- PRC 001 MaintenanceDocument8 pagesPRC 001 MaintenanceHyppolite Edgard DEUGOUE KAMENIPas encore d'évaluation

- ManuelIntegrationPaybox MIF FR-v1.4Document35 pagesManuelIntegrationPaybox MIF FR-v1.4rh007Pas encore d'évaluation

- PG DAL 280 007 Expression Du Besoin - 000Document22 pagesPG DAL 280 007 Expression Du Besoin - 000mamadou kanePas encore d'évaluation

- Instruction Sous Traitance P InterneDocument5 pagesInstruction Sous Traitance P InterneHanin BouzianePas encore d'évaluation

- Réseau Ferré Port La NouvelleDocument54 pagesRéseau Ferré Port La NouvelleM'hammed AbouzianePas encore d'évaluation

- TP 6327Document62 pagesTP 6327Exploit DévelopperPas encore d'évaluation

- Demande de Delivrance Modification Ou de Renouvellement Du CTE - F-DSA-400-OPS-06Document8 pagesDemande de Delivrance Modification Ou de Renouvellement Du CTE - F-DSA-400-OPS-06LMI contentsPas encore d'évaluation

- ConvoyeursDocument84 pagesConvoyeursHanache MadaniPas encore d'évaluation

- Measurement Canada Mesures Canada An Agency of Industry Canada Un Organisme D'industrie CanadaDocument4 pagesMeasurement Canada Mesures Canada An Agency of Industry Canada Un Organisme D'industrie CanadahecjehepPas encore d'évaluation

- Cahier de Recette SAV 05102020Document32 pagesCahier de Recette SAV 05102020hifdiPas encore d'évaluation

- VITAM Cahier de Recette FonctionnelDocument768 pagesVITAM Cahier de Recette FonctionnelllllllllllllPas encore d'évaluation

- Apv Valves sw4 FRDocument48 pagesApv Valves sw4 FRayaaithassi19Pas encore d'évaluation

- 14 01306 8.0 EPS CMP SW VC2 NotebookDocument34 pages14 01306 8.0 EPS CMP SW VC2 Notebookmonutilisation0Pas encore d'évaluation

- Norme NF P 98-501Document93 pagesNorme NF P 98-501Philippe PoiretPas encore d'évaluation

- ATV 58-Manuel - Sodivar PDFDocument51 pagesATV 58-Manuel - Sodivar PDFJustin RichardPas encore d'évaluation

- Fiche de Poste PSV01Document14 pagesFiche de Poste PSV01être InstrumePas encore d'évaluation

- Plan Inspection Echangeur de ChaleurDocument5 pagesPlan Inspection Echangeur de Chaleurzakaria khaled100% (1)

- Compte-Rendu de Verification Annuelle D'Un Systeme D'Extinction Incendie Par SprinkleursDocument14 pagesCompte-Rendu de Verification Annuelle D'Un Systeme D'Extinction Incendie Par SprinkleurskdsessionsPas encore d'évaluation

- Composition Du Dossier Préliminaire de L'équipementDocument2 pagesComposition Du Dossier Préliminaire de L'équipementPFE100% (1)

- Référentiel NF063 Tuiles - Janvier 2021Document79 pagesRéférentiel NF063 Tuiles - Janvier 2021Dalia MonteagudoPas encore d'évaluation

- Easytome 1020-1515-1530-2040: Machine de CoupageDocument40 pagesEasytome 1020-1515-1530-2040: Machine de CoupageBilel Hajri100% (1)

- Raw BM700 70131Document26 pagesRaw BM700 70131Clemens RothmannPas encore d'évaluation

- IAA 1000 FR PDFDocument400 pagesIAA 1000 FR PDFzizouhichePas encore d'évaluation

- Notice Utilisation Digicode Noralsy Provic One X2Document23 pagesNotice Utilisation Digicode Noralsy Provic One X2paitierPas encore d'évaluation

- TRAITEMENT OFFRE CLIENTDocument5 pagesTRAITEMENT OFFRE CLIENTelhousni.kh09Pas encore d'évaluation

- 13-Po-Hse-10 - Gestion Des Sous Traitants Et Fournisseurs Rev 00Document5 pages13-Po-Hse-10 - Gestion Des Sous Traitants Et Fournisseurs Rev 00Armand NKOUNKOU100% (3)

- Referentiel NF Chambres TelecommunicationsDocument79 pagesReferentiel NF Chambres Telecommunicationschonger19970311Pas encore d'évaluation

- 258731472Document19 pages258731472Ayoub Magroud100% (1)

- 1 2016-07-05 Dec 014 Portant Adoption Du RAG 9 Relatif A La Gestion de La Securite 2Document25 pages1 2016-07-05 Dec 014 Portant Adoption Du RAG 9 Relatif A La Gestion de La Securite 2florentPas encore d'évaluation

- Info Iecfdis61378 3 (Ed2.0) BDocument23 pagesInfo Iecfdis61378 3 (Ed2.0) BJjamer Jjamer Jjamer50% (2)

- La Signalisation Vderticale Et HorizontaleDocument38 pagesLa Signalisation Vderticale Et Horizontaletafisco550550% (2)

- Referentiel NF Elements Structure Lineaires PDFDocument53 pagesReferentiel NF Elements Structure Lineaires PDFZeina NounPas encore d'évaluation

- nf202 Referentiel de Certification Du 1 Octobre 2018 011018Document44 pagesnf202 Referentiel de Certification Du 1 Octobre 2018 011018Menasri LounesPas encore d'évaluation

- Cofrac AcDocument21 pagesCofrac AcfouedPas encore d'évaluation

- CDC - Controle Regle. - Esp - DTM - 2023Document13 pagesCDC - Controle Regle. - Esp - DTM - 2023gccsecretariat1Pas encore d'évaluation

- Referentiel NF Elements ArchitecturauxDocument88 pagesReferentiel NF Elements ArchitecturauxWladimir CRPas encore d'évaluation

- Reporting pilier 3 de solvabilité II: Guide pour la production des QRTD'EverandReporting pilier 3 de solvabilité II: Guide pour la production des QRTPas encore d'évaluation

- Distr ProbaDocument37 pagesDistr ProbaOumaima OughnimaPas encore d'évaluation

- Syllabus LAITS ET PRODUITS LAITIERS - 2Document3 pagesSyllabus LAITS ET PRODUITS LAITIERS - 2Gedion DouaPas encore d'évaluation

- Dictionnaire Amoureux Des Dieux Et Des DéessesDocument273 pagesDictionnaire Amoureux Des Dieux Et Des DéessesKone Assane100% (1)

- Act2 1Document4 pagesAct2 1nassima ghallabiPas encore d'évaluation

- Exam MDMDocument4 pagesExam MDMHaithem AminePas encore d'évaluation

- Item 362 - AesDocument4 pagesItem 362 - AesSofia RhellabPas encore d'évaluation

- TIG Ta33 Panneau de Commande FRDocument22 pagesTIG Ta33 Panneau de Commande FRk.a55Pas encore d'évaluation

- Cours 3 ProthèseDocument4 pagesCours 3 ProthèseDDan2005Pas encore d'évaluation

- PDFDocument24 pagesPDFCompétitionPas encore d'évaluation

- Catalogue PHOTOFLEX en FrancaisDocument26 pagesCatalogue PHOTOFLEX en FrancaisAllanlitwinPas encore d'évaluation

- Introduction A L'immunologieDocument9 pagesIntroduction A L'immunologieBalakibawi ESSOPas encore d'évaluation

- Enquête de Fréquentation Culturelle 2015 PDFDocument35 pagesEnquête de Fréquentation Culturelle 2015 PDFilikesummer1234Pas encore d'évaluation

- Soukhoï Su-57 - WikipédiaDocument10 pagesSoukhoï Su-57 - WikipédiaMohamed Lamine TourePas encore d'évaluation

- Examples Questions Examen AcoustiqueDocument4 pagesExamples Questions Examen AcoustiquePierreFontenellePas encore d'évaluation

- Exos PDT Conjugaison G1Document16 pagesExos PDT Conjugaison G1Olivier Benard100% (1)

- Mur Types PDFDocument76 pagesMur Types PDFWafaa ElyaâgoubiPas encore d'évaluation

- NF EN 1993-1-7 NA Aout 2008Document4 pagesNF EN 1993-1-7 NA Aout 2008fauvyPas encore d'évaluation

- Sup'air SellettesDocument1 pageSup'air SellettesStefanoPas encore d'évaluation

- Hygiène HospitalièreDocument4 pagesHygiène HospitalièreJamal MalouPas encore d'évaluation

- AFAM - Projet de RechercheDocument23 pagesAFAM - Projet de RechercheAlbert Francis Abega MekongoPas encore d'évaluation

- Methode de TravailDocument2 pagesMethode de Travailamal akhoulouPas encore d'évaluation

- Jeremie Gouyon Ok-2Document289 pagesJeremie Gouyon Ok-2leucinedijaPas encore d'évaluation

- Cours de Gestion de Production 1.2.3 Gmp2 VPDocument30 pagesCours de Gestion de Production 1.2.3 Gmp2 VPMohamed SabrePas encore d'évaluation

- Estem: Eau Dans Le SolDocument27 pagesEstem: Eau Dans Le SolAlli BoukhchPas encore d'évaluation

- Matièreexamen 4 Ème Aet DDocument6 pagesMatièreexamen 4 Ème Aet DToby 17Pas encore d'évaluation

- AUguste Blanqui L'Éternité Par Les AstresDocument79 pagesAUguste Blanqui L'Éternité Par Les AstresYvan KalievPas encore d'évaluation

- S o Mortaiseuse MechesDocument2 pagesS o Mortaiseuse Mechesp bwPas encore d'évaluation

- Structure REFECTOIRE SODIGAZ PDFDocument44 pagesStructure REFECTOIRE SODIGAZ PDFheheheyPas encore d'évaluation

- Sco BP1Document5 pagesSco BP1Philippe Diego DelasvegasPas encore d'évaluation

- Les Thèmes Du Dalf C1Document28 pagesLes Thèmes Du Dalf C1Ioana Babarus100% (1)